Grinding machine parameter testing and analytical system

A technology of parameter detection and analysis system, used in grinding machine parts, workpiece feed motion control, grinding/polishing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

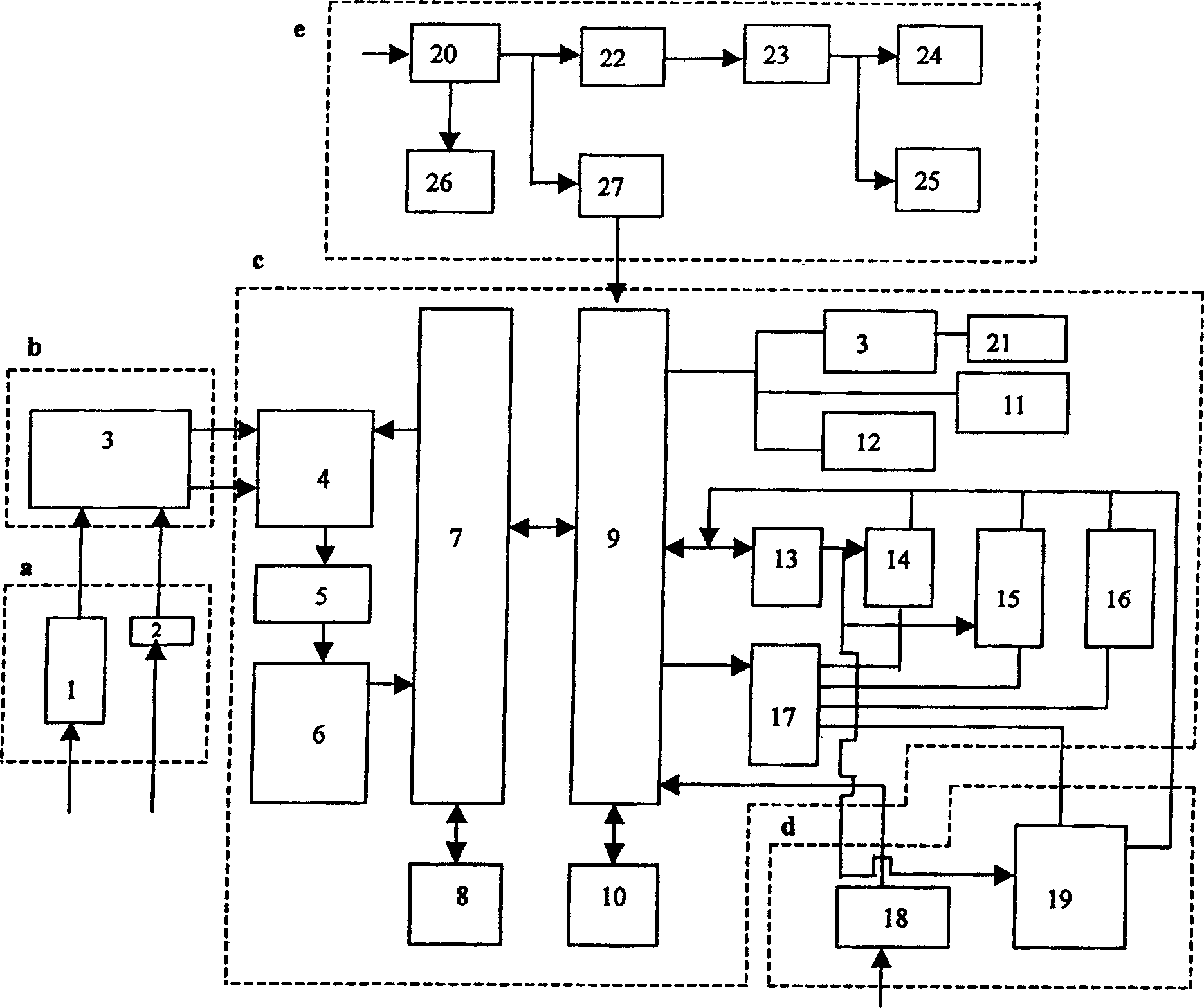

[0019] Such as figure 1 As shown, the present invention includes:

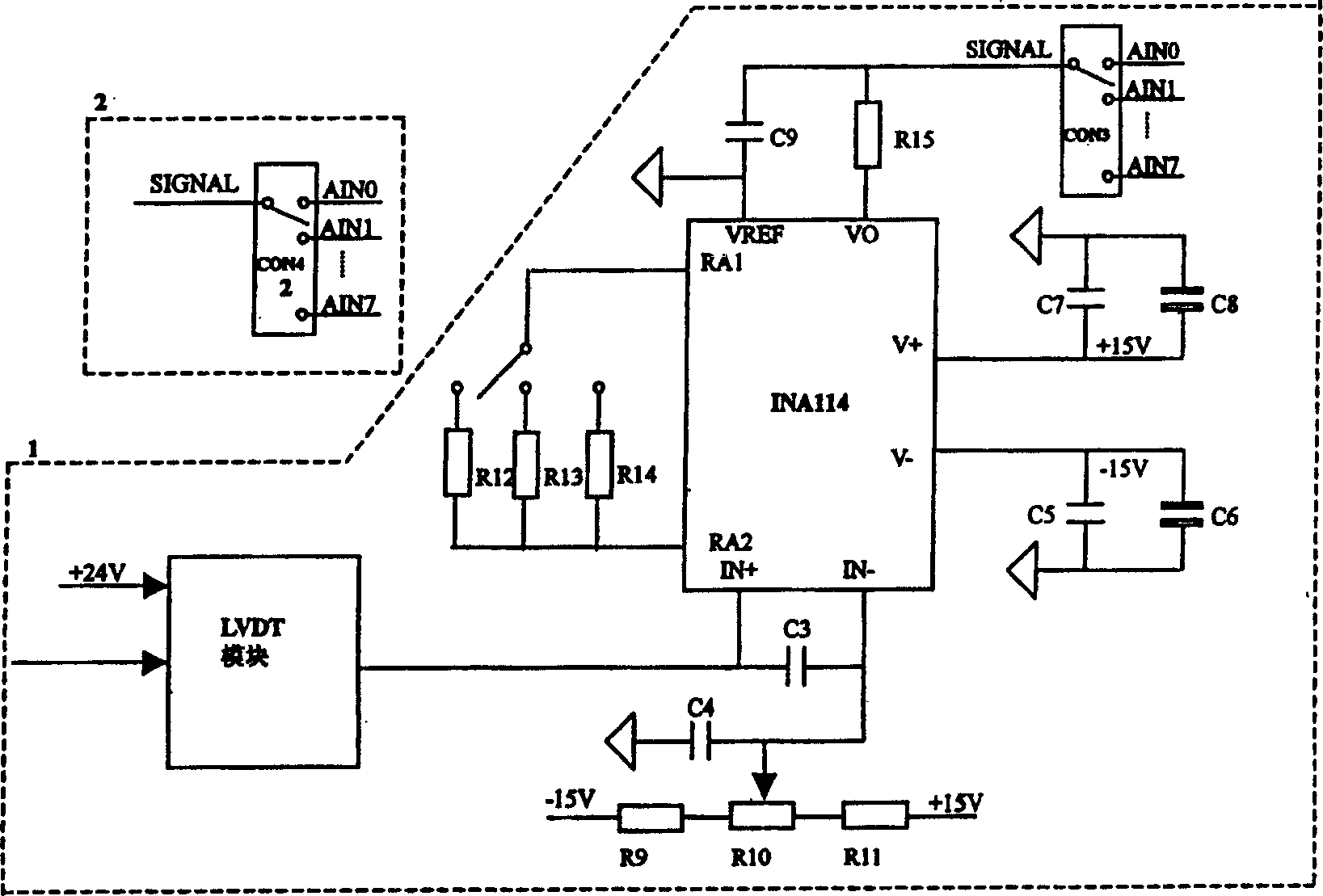

[0020] 1) Detection signal preprocessing board module a: includes a first acquisition board 1 connected to the sensor signal for detecting the feed rate of the grinding machine at one end, and connected to a signal input end of the expansion board 3 at the other end; The second acquisition board 2 that is connected to the sensor signal, and the other end is connected to the other signal input end of the expansion board 3 . The sensor signal for detecting the feed rate of the grinding machine is input to the first acquisition board 1, and then input to the expansion board 3 after being conditioned by the LVDT and amplified by the signal amplification circuit. The sensor signal for detecting the power of the main motor of the grinding machine is selected by the second acquisition board 2 and then input to the expansion board 3 .

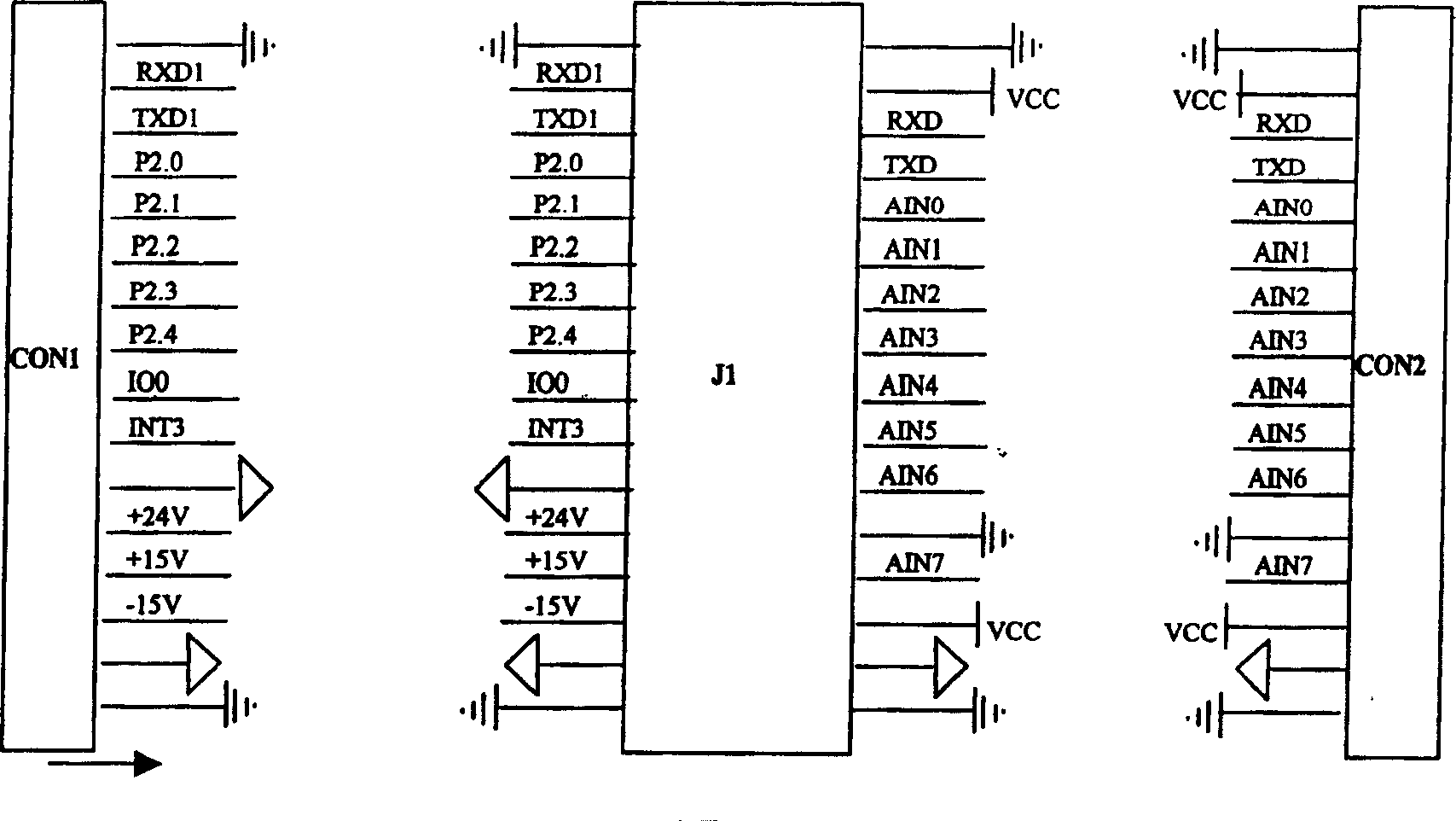

[0021] 2) Expansion board module b: includes an expansion board 3 whose two inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com