Low-speed airflow drying equipment

An airflow drying and equipment technology, which is applied in the direction of drying gas arrangement, lighting and heating equipment, drying, etc., can solve the problems of unguaranteed quality of dried materials, reduced drying efficiency, and poor drying effect, so as to improve the uniformity of moisture content, Improve the sensory quality and reduce the extreme difference in moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

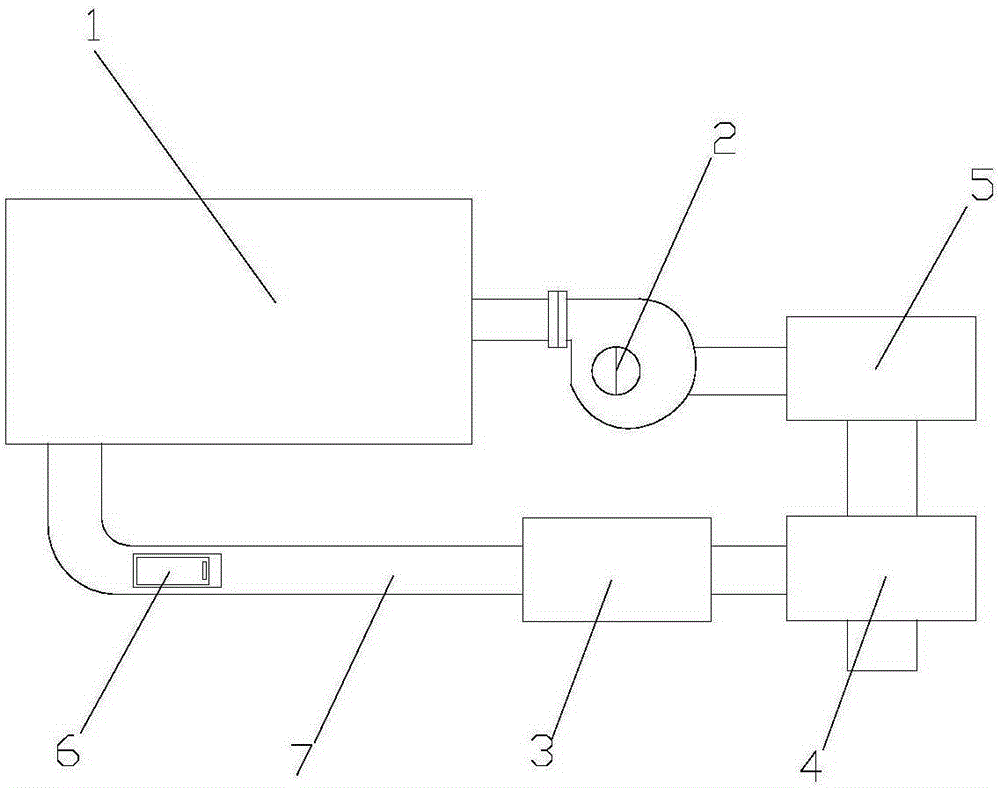

[0021] This embodiment provides a low-speed airflow drying device with a structure such as figure 1 As shown, it includes a hot blast boiler 1, an induced draft fan 2, an airflow drying chamber 3, a gas material cyclone separator 4 and a bag filter 5. The air outlet of the hot blast boiler is connected to the air inlet of the airflow drying chamber through a feeding pipeline 7. On the feeding pipeline, There is a feed inlet 6, the air outlet of the airflow drying chamber is connected with the gas material separator, the exhaust gas outlet of the gas material separator is connected with the dust collector, and the air outlet of the dust collector is connected with the air inlet of the hot blast boiler through the induced draft fan; The inner wall of the feeding pipe and air drying chamber is coated with an anti-adhesive coating. The anti-adhesive coating includes the following components in parts by mass: novolac epoxy resin: 55 parts, pigments and fillers: 13 parts, KH560 silan...

Embodiment 2

[0033] This embodiment provides a low-speed airflow drying device, the structure is the same as that of Embodiment 1, the difference lies in the components of the anti-adhesive coating, and the anti-adhesive coating includes the following components in parts by mass: novolac epoxy resin: 57 Parts, pigments and fillers: 14 parts, KH560 silane coupling agent: 5 parts, ethylenediamine curing agent: 5 parts, polyvinyl acetate: 3 parts, ammonium molybdate: 4 parts, polymethylphenylsiloxane: 5 parts, zinc borate: 5 parts, solvent: 31 parts, barium sulfate: 7 parts;

[0034] The solvent is a mixed solvent of cyclohexanone and n-butanol, and the volume ratio of cyclohexanone and n-butanol is 3.5:1; the fineness of the pigment and filler is 150 mesh, and the pigment and filler include the following components in parts by mass: barium sulfate: 16 parts, talcum powder: 8 parts, lead oxide: 8 parts, carbon black: 4 parts, zinc powder: 3 parts;

[0035] The preparation method of the novol...

Embodiment 3

[0045] This embodiment provides a low-speed airflow drying device, the structure is the same as that of Embodiment 1, the difference lies in the components of the anti-adhesive coating, and the anti-adhesive coating includes the following components in parts by mass: novolak epoxy resin: 59 Parts, pigments and fillers: 15 parts, KH560 silane coupling agent: 7 parts, polyamide-650: 7 parts, silicone: 4 parts, ammonium molybdate: 6 parts, acrylic acid: 7 parts, zinc borate: 6 parts, solvent : 38 parts, barium sulfate: 10 parts;

[0046] The solvent is a mixed solvent of cyclohexanone and n-butanol, and the volume ratio of cyclohexanone and n-butanol is 3.5:1; the fineness of the pigment and filler is 200 mesh, and the pigment and filler include the following components in parts by mass: barium sulfate: 18 parts, talcum powder: 10 parts, lead oxide: 10 parts, carbon black: 5 parts, zinc powder: 5 parts;

[0047] The preparation method of the novolac epoxy resin in the anti-adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com