Pipeline steel with high acid medium corrosion resistance and production method thereof

A technology of acidic medium and production method, applied in the direction of manufacturing converters, etc., to achieve the effect of reducing production costs, optimizing process parameters, reducing types and additions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

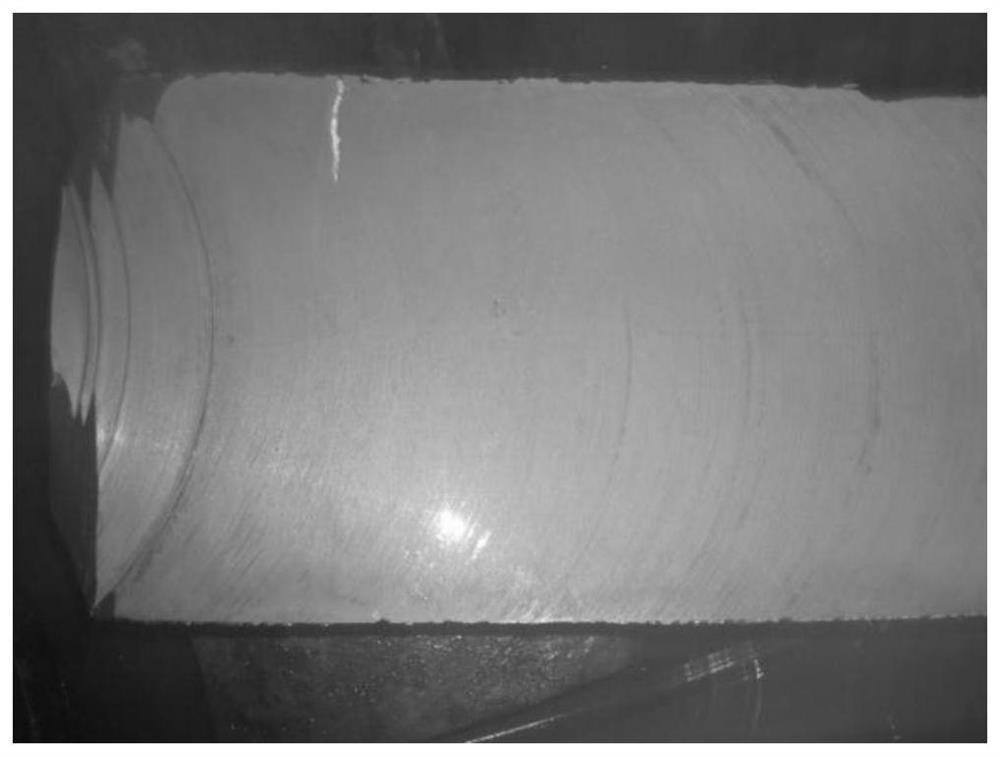

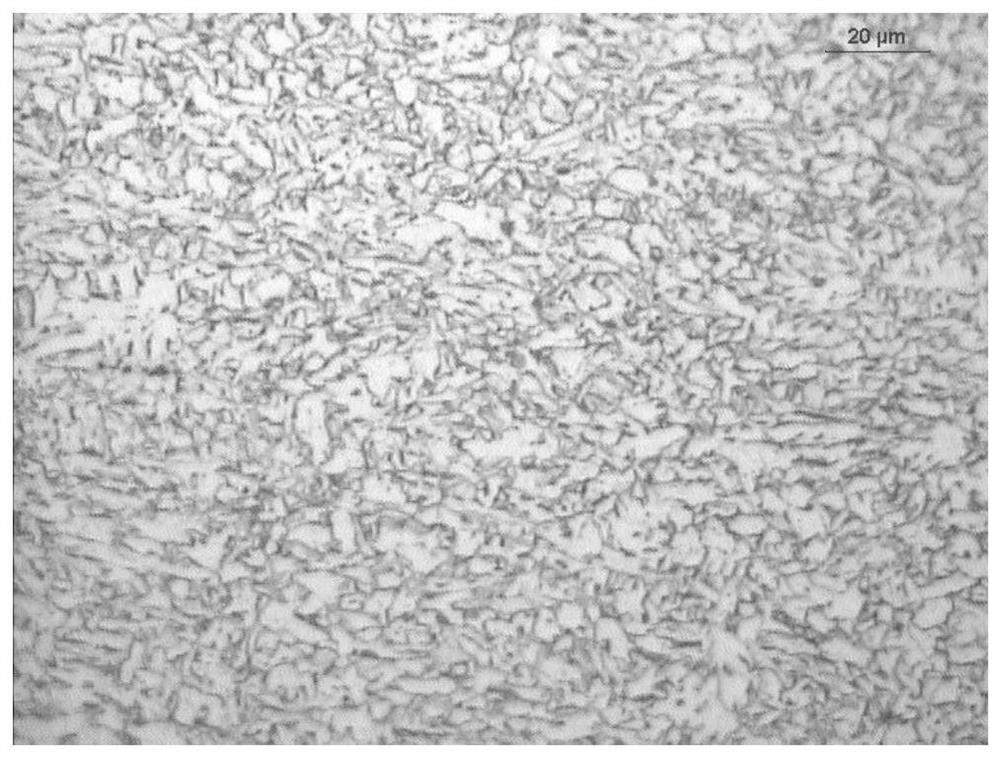

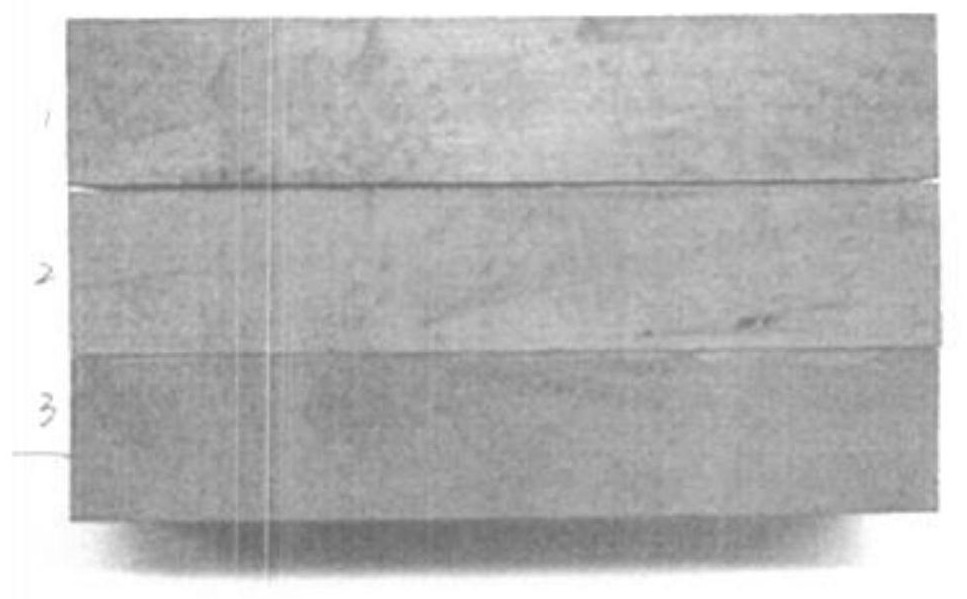

Embodiment 1

[0031] For pipeline steel with a thickness of 3mm and high resistance to acidic medium corrosion, the steelmaking is carried out according to the design process, and the steel rolling is produced according to the original process. The composition and process parameters of the finished product are C: 0.035%, Si: 0.20%, Mn: 1.30%, P: 0.008%, S: 0.001%, Als: 0.035%, Nb: 0.050%, Mo: 0.10%, Ti: 0.010%. The amount of steel scrap added to the converter is 30 tons, and the amount of oxygen blowing is 13000Nm 3 , the end point oxygen is 700ppm, the amount of lime added in the blowing process is 12 tons, the tapping C: 0.025%, the tapping P: 0.007%, the tapping temperature is 1610°C, and the amount of lime added in the tapping process is 0.75 tons. The amount of lime added in the LF refining process is 2.4 tons. At the same time, the first-level computer operating system is used to automatically adjust the opening of the air valve to ensure the slight positive pressure in the ladle furn...

Embodiment 2

[0035] For pipeline steel with a thickness of 3mm and high resistance to acidic medium corrosion, the steelmaking is carried out according to the design process, and the steel rolling is produced according to the original process. The composition and process parameters of the finished product are C: 0.025%, Si: 0.10%, Mn: 1.10%, P: 0.009%, S: 0.0008%, Als: 0.015%, Nb: 0.030%, Mo: 0.16%, Ti: 0.020%. 25 tons of steel scrap added to the converter, 14000Nm of oxygen blowing 3 , the end point oxygen is 900ppm, the amount of lime added in the blowing process is 13 tons, the tapping C: 0.020%, the tapping P: 0.008%, the tapping temperature is 1630°C, and the amount of lime added in the tapping process is 1 ton. The amount of lime added in the LF refining process is 2.5 tons. At the same time, the first-level computer operating system is used to automatically adjust the opening of the air valve to ensure the slight positive pressure in the ladle furnace during the entire smelting proc...

Embodiment 3

[0039] For pipeline steel with a thickness of 3mm and high resistance to acidic medium corrosion, steelmaking is carried out according to the design process, and steel rolling is produced according to the original process. The composition and process parameters of the finished product are C: 0.030%, Si: 0.15%, Mn: 1.20%, P: 0.008%, S: 0.0006%, Als: 0.020%, Nb: 0.044%, Mo: 0.14%, Ti: 0.015%. 25 tons of steel scrap added to the converter, 13500Nm of oxygen blowing 3 , the end point oxygen is 800ppm, the amount of lime added in the blowing process is 12.5 tons, the tapping C: 0.022%, the tapping P: 0.007%, the tapping temperature is 1620°C, and the amount of lime added in the tapping process is 0.9 tons. The amount of lime added in the LF refining process is 2.45 tons. At the same time, the first-level computer operating system is used to automatically adjust the opening of the air valve to ensure the slight positive pressure in the ladle furnace during the entire smelting proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com