Eccentric rotator and flat type motor having same

An eccentric rotor, eccentric technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve problems such as efficiency deterioration, and achieve the effects of reducing bearing loss, sufficient starting torque, and less pressing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the configuration of the present invention will be described with reference to various embodiments shown in the drawings.

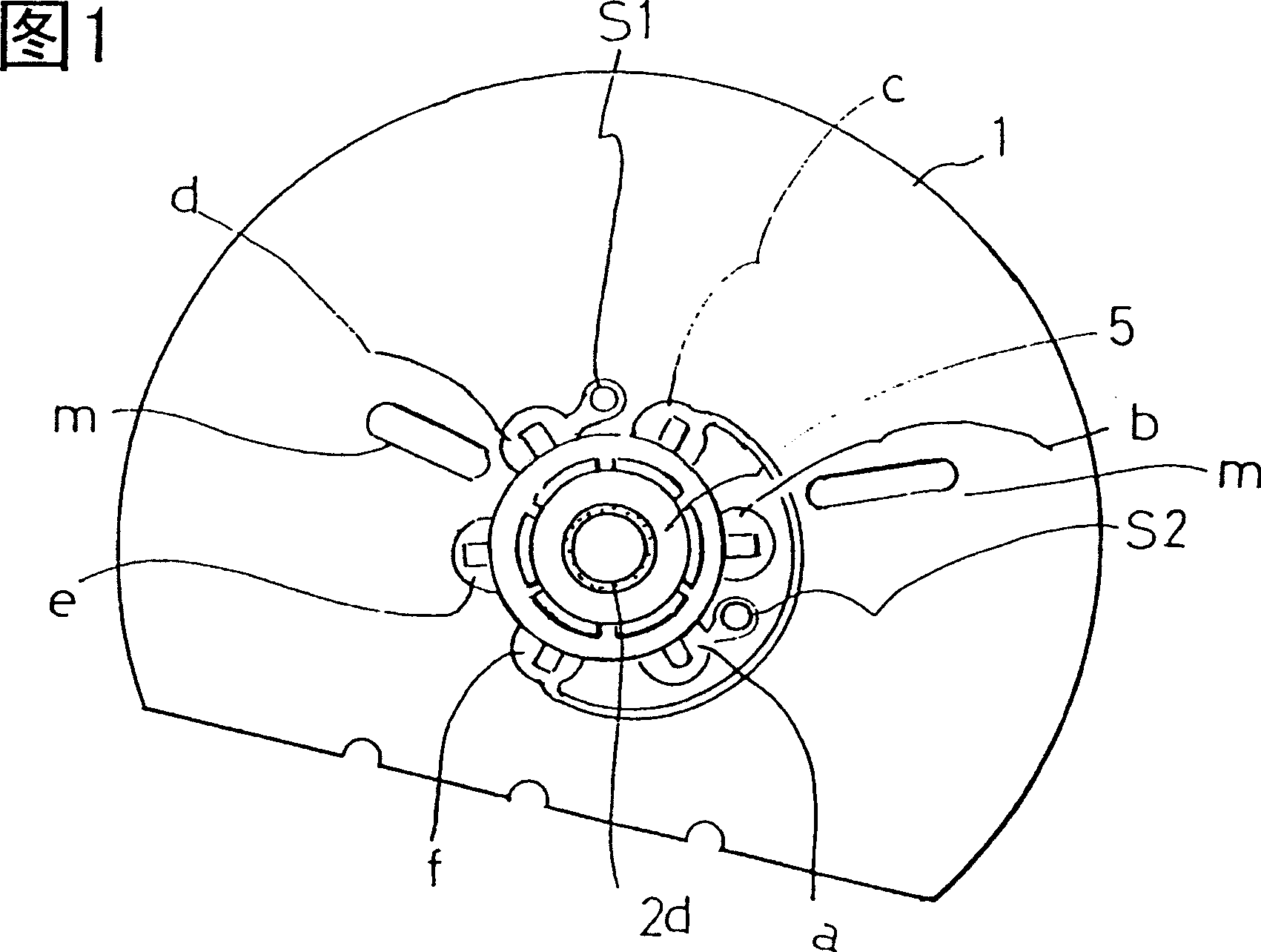

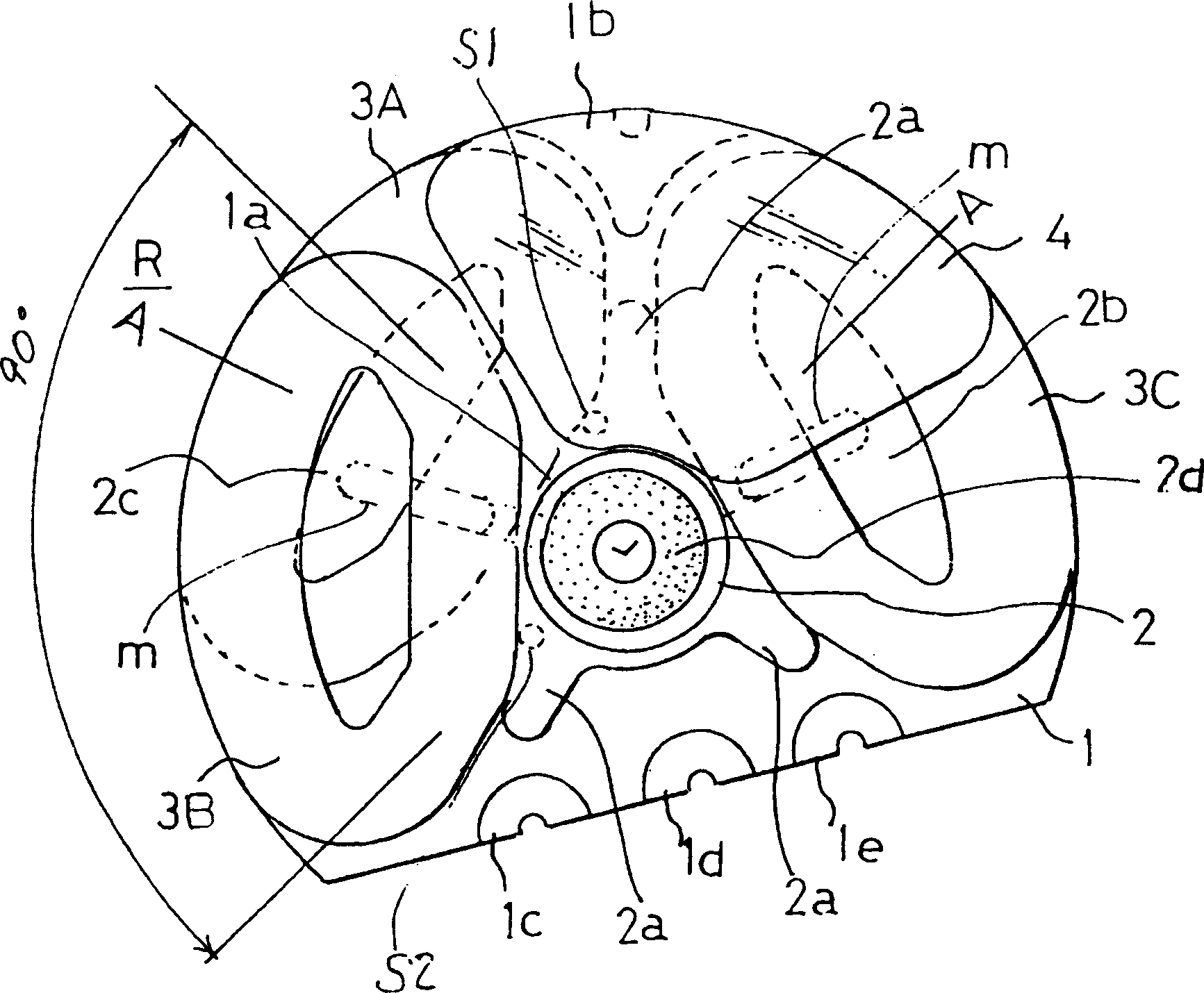

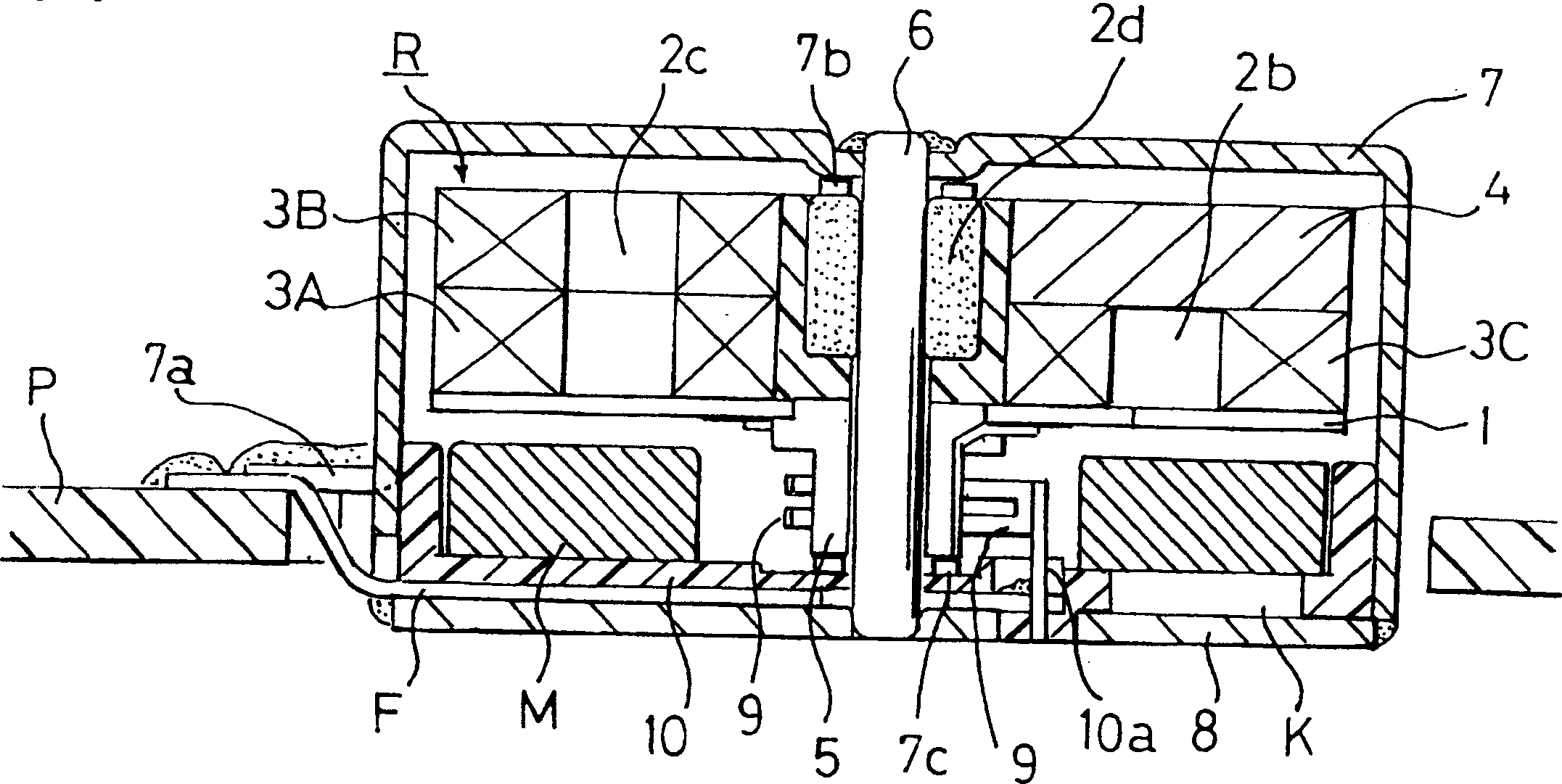

[0039] Fig. 1 is a plan view showing a main part of an eccentric rotor according to a first embodiment of the present invention, viewed from a commutator side. figure 2 is a plan view of the main part of the above-mentioned eccentric rotor viewed from the side opposite to the commutator. image 3 Yes means cut off by line A-A figure 2 It is a cross-sectional view of the flat vibration motor of the present invention housed in the state of the rotor shown. Figure 4 is image 3 An explanatory diagram of the operation of the shown motor. 5 is a plan view showing an eccentric rotor according to a modified example of the first embodiment. Fig. 6 is a plan view showing the main parts of the eccentric rotor according to the second embodiment, seen from the commutator side. Figure 7 It is a longitudinal sectional view of the flat vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com