Detecting method and structure for microstructure binding process

A bonding process and detection method technology, which is applied in the direction of applying stable shear force to test the strength of materials, instruments, scanning probe technology, etc., can solve the problem that the bonded sample should not be too small to reflect the bond strength , Can not accurately reflect the microstructure bonding strength and other issues, to achieve the effect of improving the processing yield of MEMS devices, convenient detection, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is mainly applicable to MEMS microstructures produced by the bonding strength detection of various microstructures using bonding techniques (for example: silicon-glass bonding, silicon ICP deep etching), and the present invention can also be used in other forms of bonding (such as silicon fusion bonding direct, adhesive bonding bonding, etc.) detection of microstructure bonding strength.

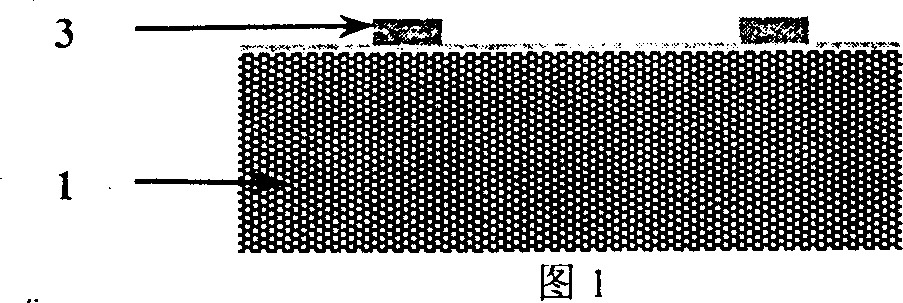

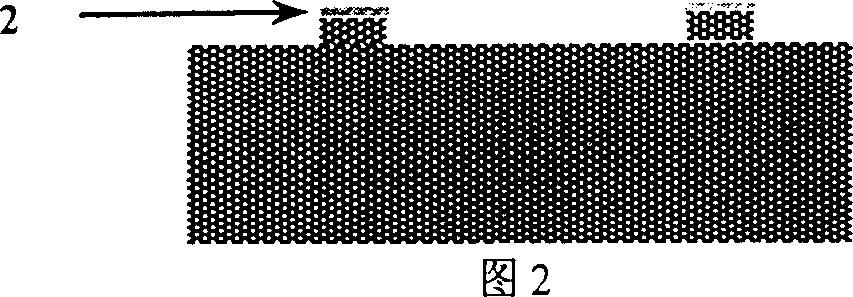

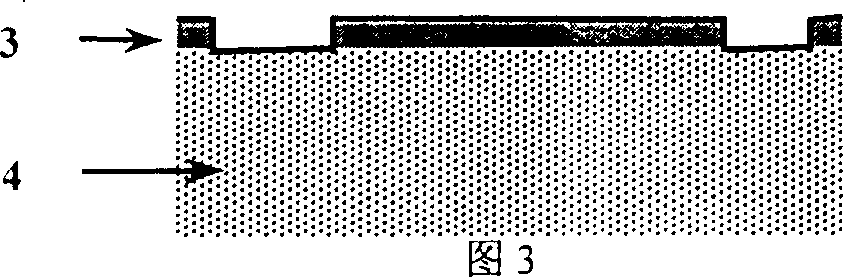

[0045] In this embodiment, the process of silicon-glass bonding and silicon ICP deep etching is specifically described, but the application of the present invention to other bonding methods is not limited. The specific process flow is shown in Figures 1-7 and their descriptions.

[0046] Silicon-glass bonding part:

[0047] In order to increase the bonding strength, necessary cleaning is performed on the bonding surfaces of the silicon structure wafer before the bonding alignment between the bonding surfaces is performed. Especially for silicon structural wafers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com