Regeneration technique for fumes and gas flue in imperfect combustion

A combustion method, a technology of complete regeneration, applied in chemical instruments and methods, catalyst regeneration/reactivation, hydrocarbon oil cracking, etc., can solve the problems of increased energy consumption of the device, complicated control, low efficiency of the hood, etc., to improve the recovery power , the effect of flexible control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

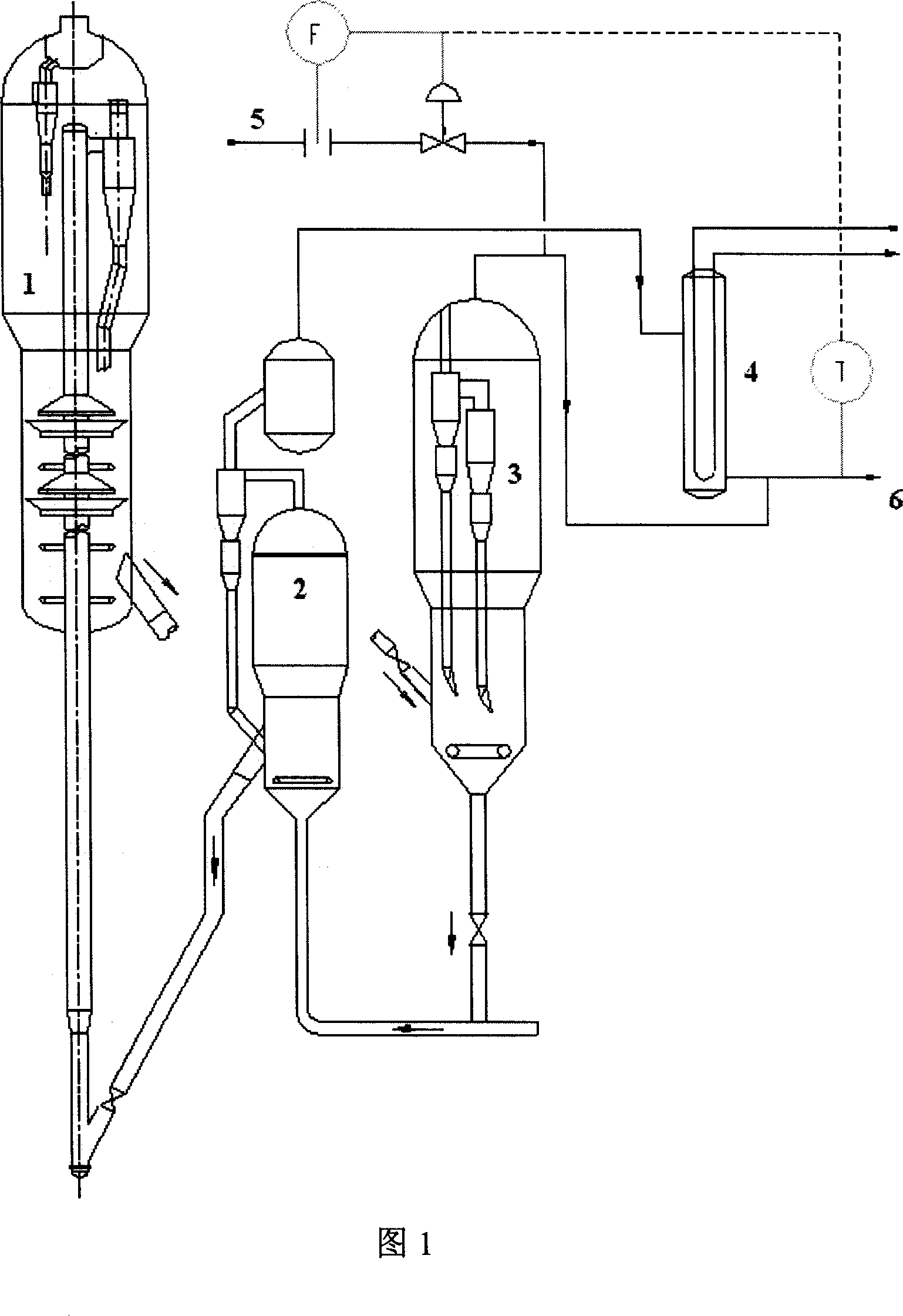

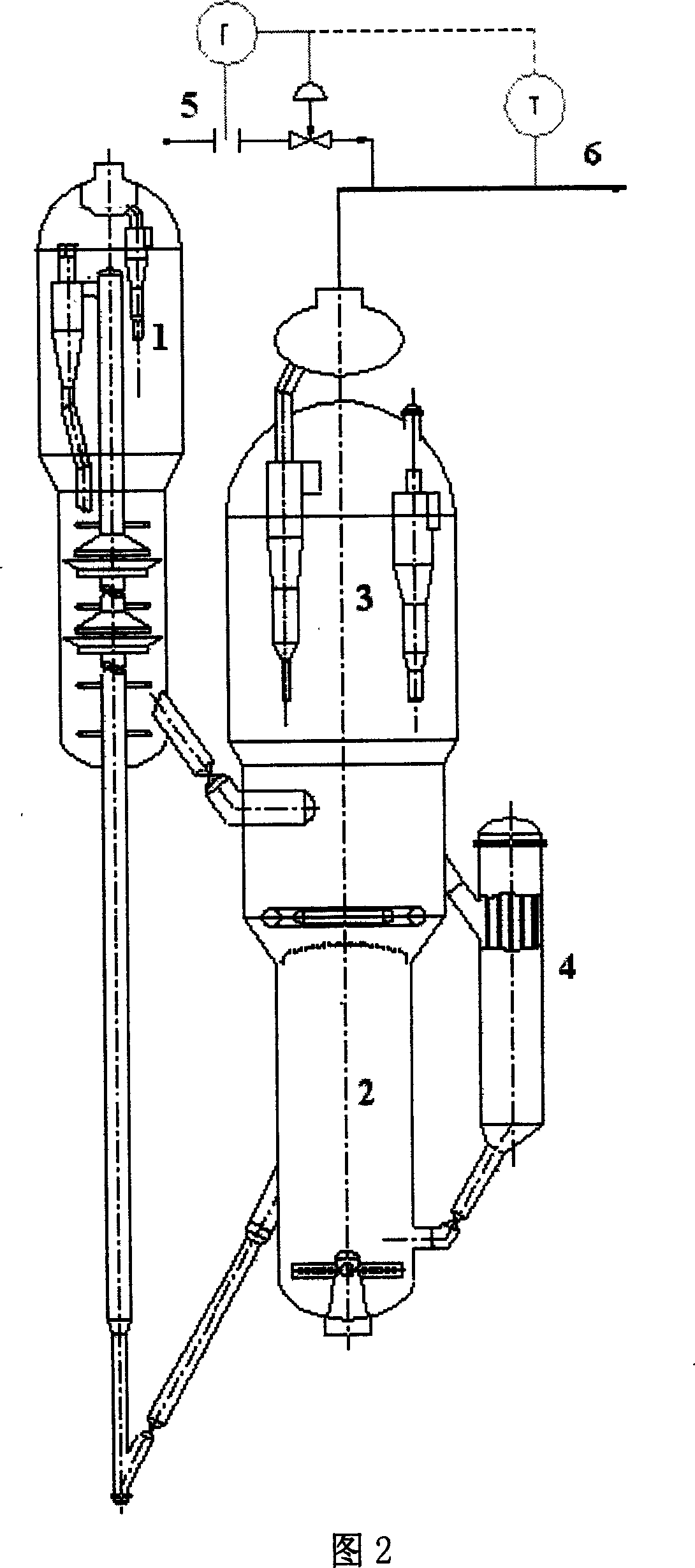

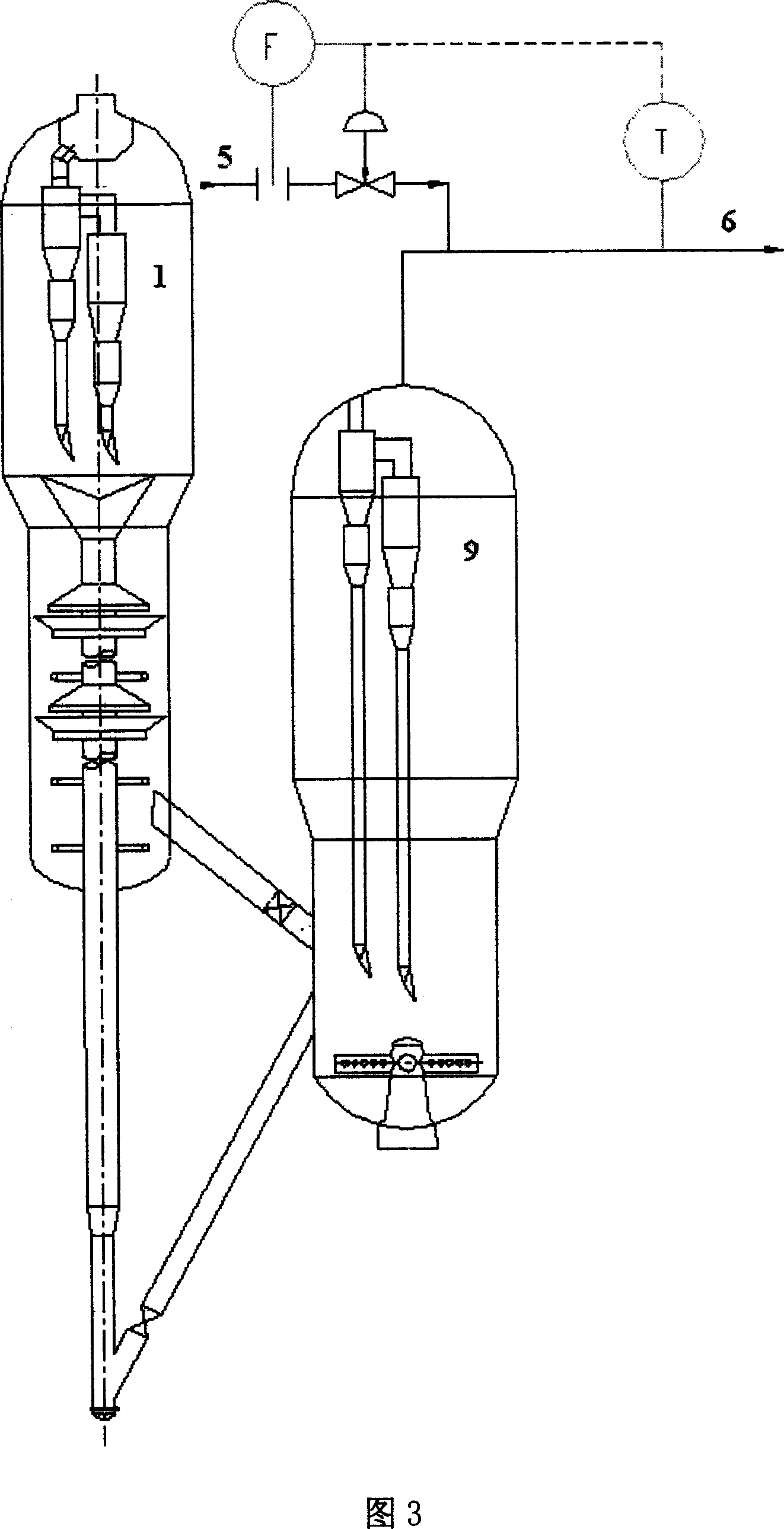

[0021] For the overlapping two-stage regeneration of the 1.4 million tons / year heavy oil catalytic cracking unit, implement the technical transformation of the present invention (see Fig. 4).

[0022] The raw catalyst enters the first regenerator 3 from the reactor 1 through the inclined pipe to be raw, and is partially burnt in the third, and the catalyst that still contains part of coke enters the second regenerator 2 through the external heat extractor 4 and continues to burn. The catalyst is regenerated to restore its activity, and enters the riser through the regeneration inclined pipe for recycling. The bottom of 2 and 3 are both fed with fresh air, the excess of oxygen in 3 is complete regeneration, the flue gas containing oxygen enters 2 after combustion, and the 2 is incomplete regeneration, the flue gas after combustion contains CO comes out from the top of 2 and enters the flue . Add air in the flue, and the air is drawn out from the air distribution ring by four b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com