Device and method for preheating combustibles in combined gas and turbine installations

A steam turbine and combined technology, which is applied in the direction of steam engine devices, mechanical equipment, turbine/propellant fuel delivery systems, etc., can solve the problems of high processing and maintenance costs, rarely achieved, sensitive to temperature changes of fuel preheaters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

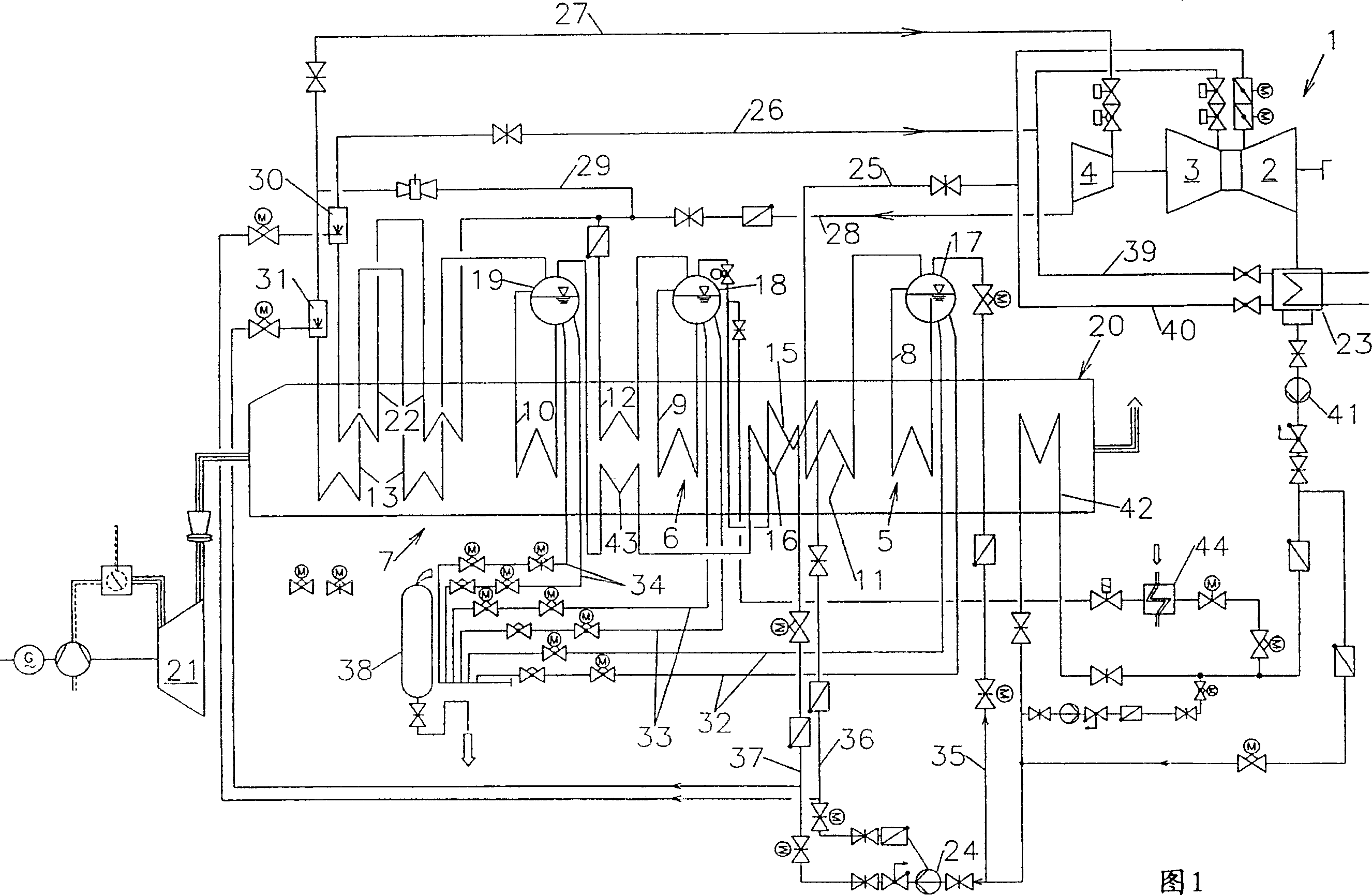

[0029] FIG. 1 shows a gas and steam turbine plant in schematic form. The steam turbine unit 1 consists of three turbine stages 2 , 3 , 4 , namely a low-pressure steam stage 2 , a medium-pressure steam stage 3 and a high-pressure steam stage 4 . The turbine stages 2 , 3 , 4 are each supplied with steam via three steam generators 5 , 6 , 7 , namely a low-pressure steam generator 5 , a medium-pressure steam generator 6 and a high-pressure steam generator 7 .

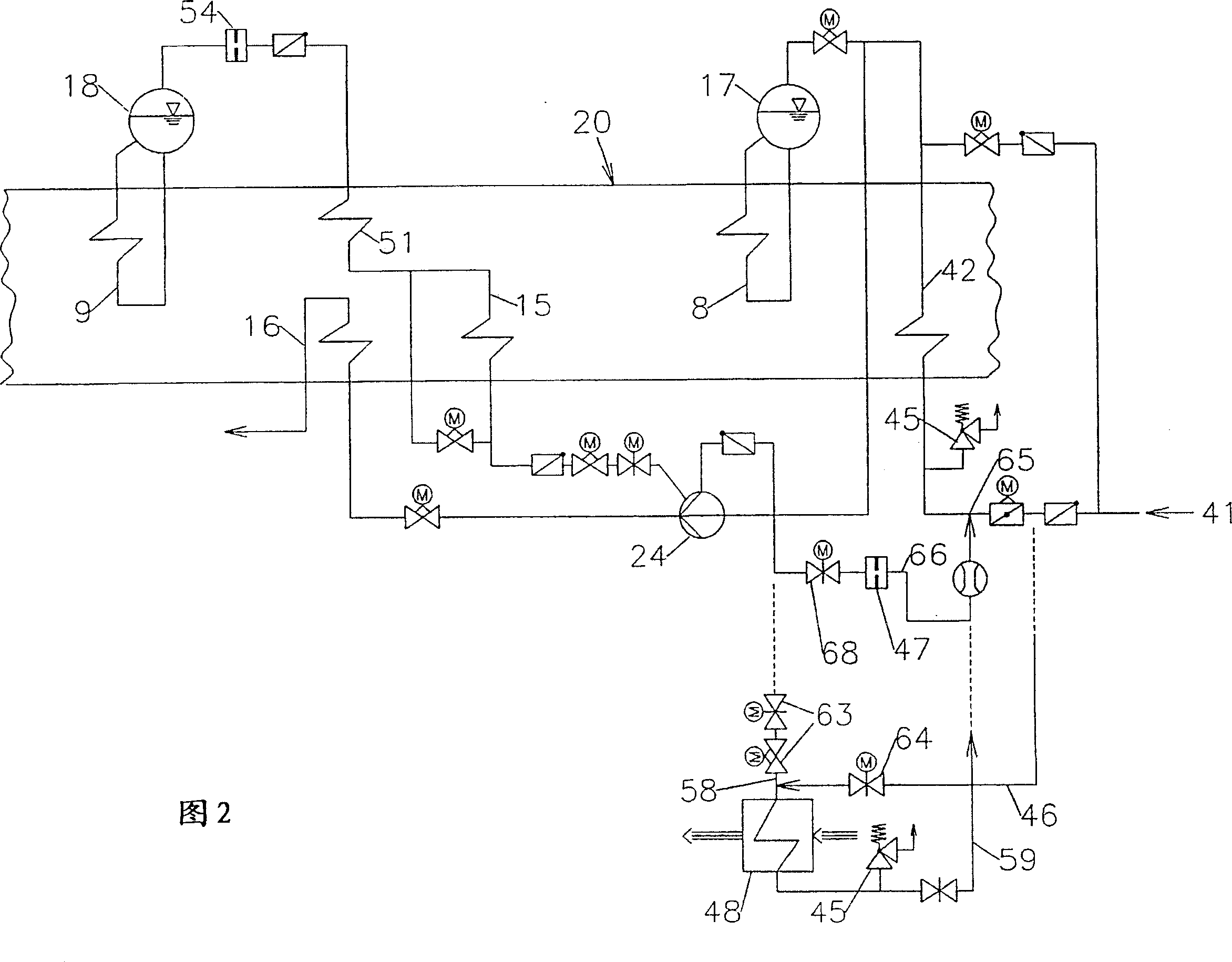

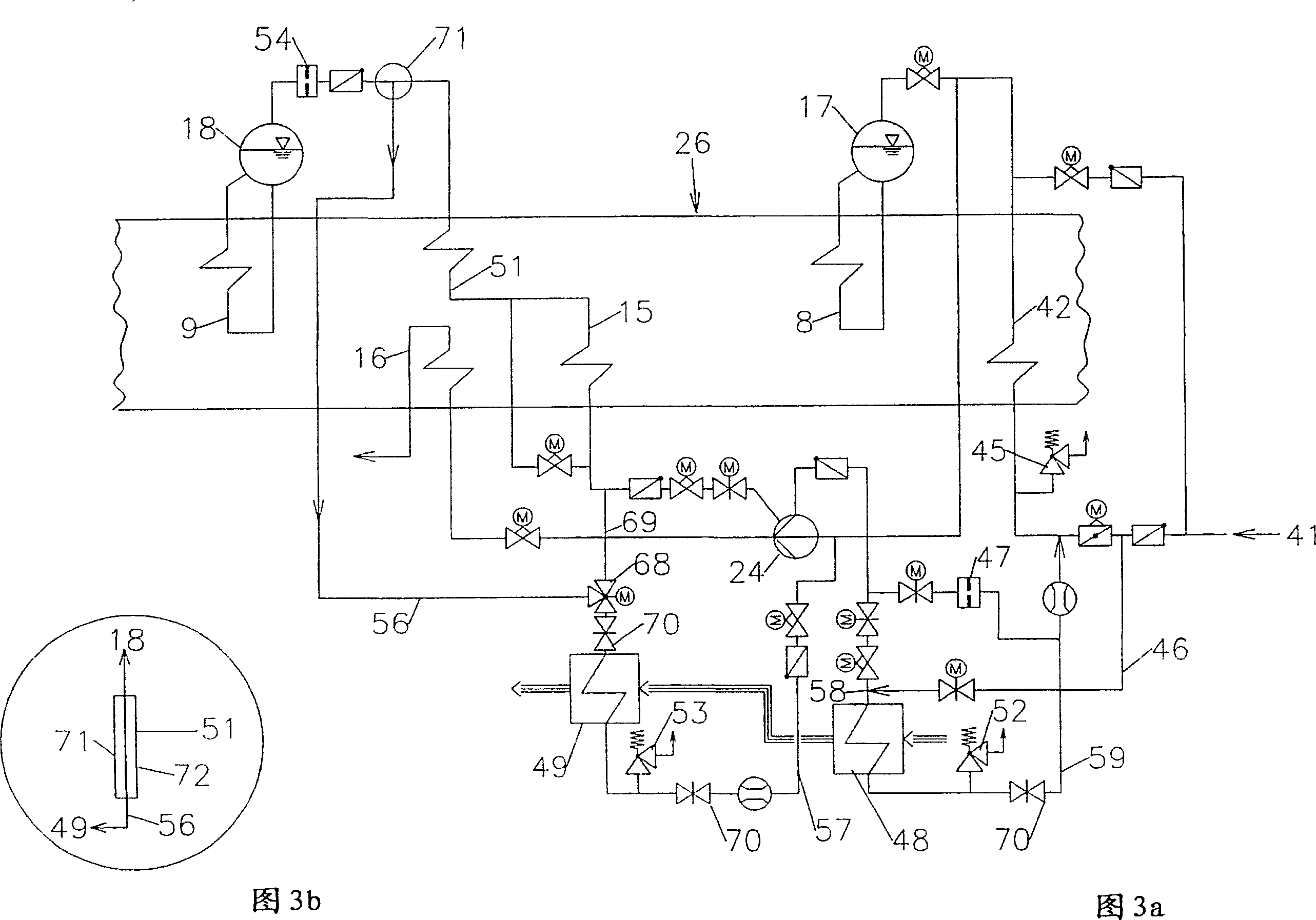

[0030]The steam generators 5, 6, 7 are of similar construction in principle. These steam generators 5,6,7 are respectively composed of an evaporator 8,9,10, a superheater 11,12,13, a condensation preheater 42 or a feed water preheater 15,16 and a steam drum 17, 18 , 19 , and a heat source 20 , in which feedwater condensate and feedwater steam are collected in a steam drum, which heat source 20 is supplied by the exhaust gas of a gas turbine 21 in the illustrated case.

[0031] The feed water is first preheated in a conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com