Gas dissolving device

A technology of dissolving device and gas, applied in the directions of dissolving, dissolving, transportation and packaging, can solve the problems of high water discharge, increased manufacturing cost, and reduced oxygen dissolved amount, etc., to reduce manufacturing cost, reduce maintenance cost, and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

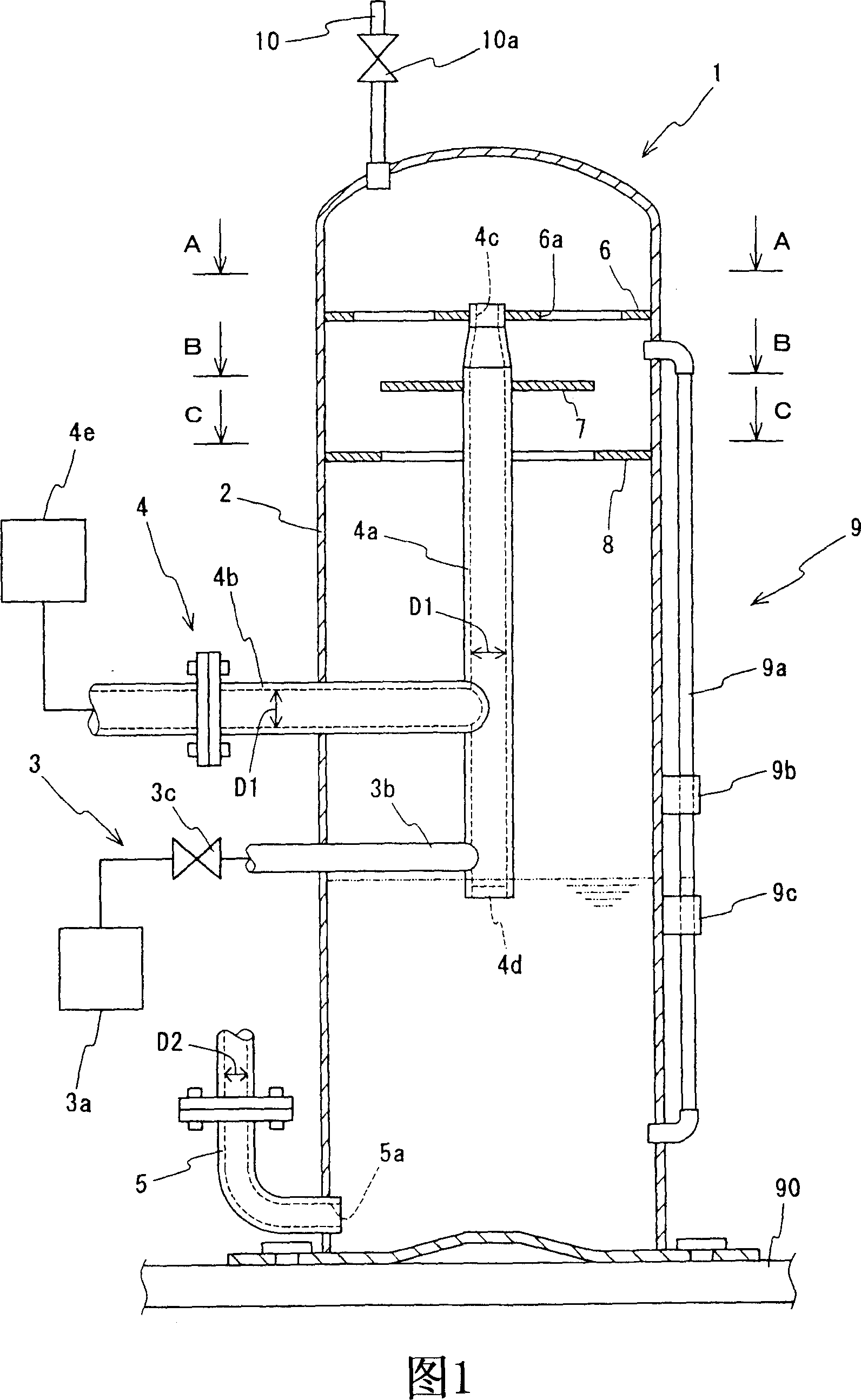

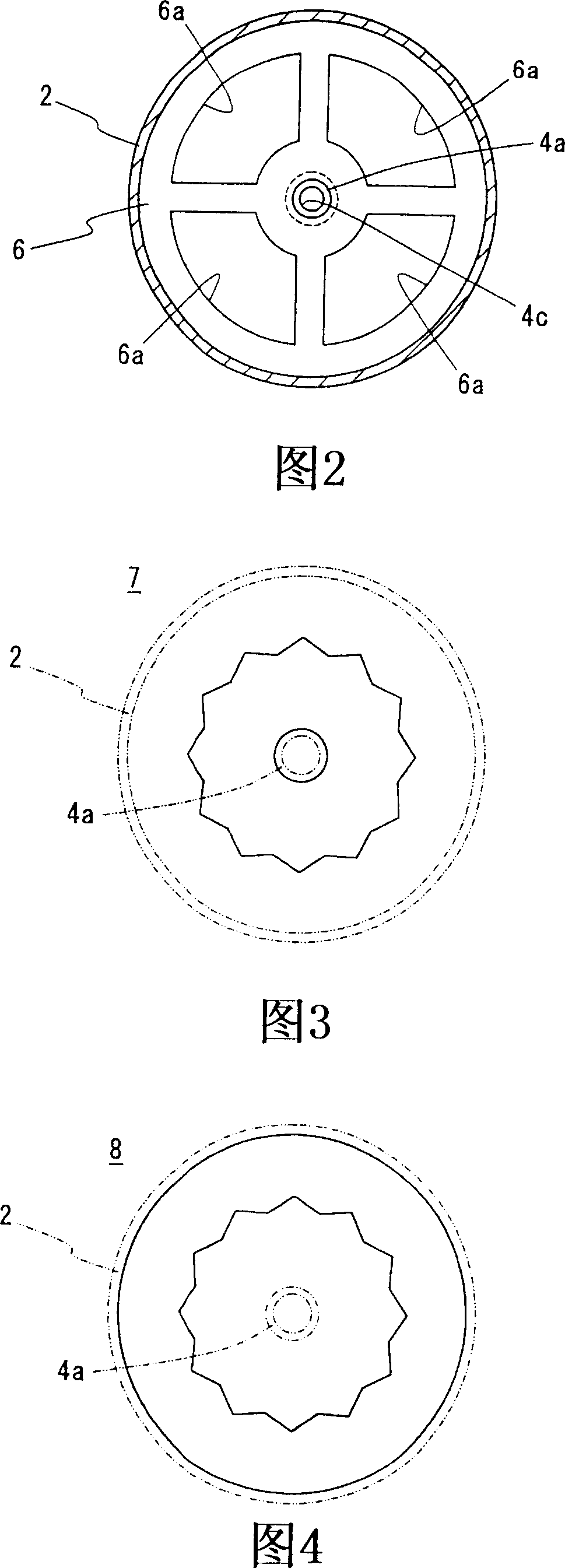

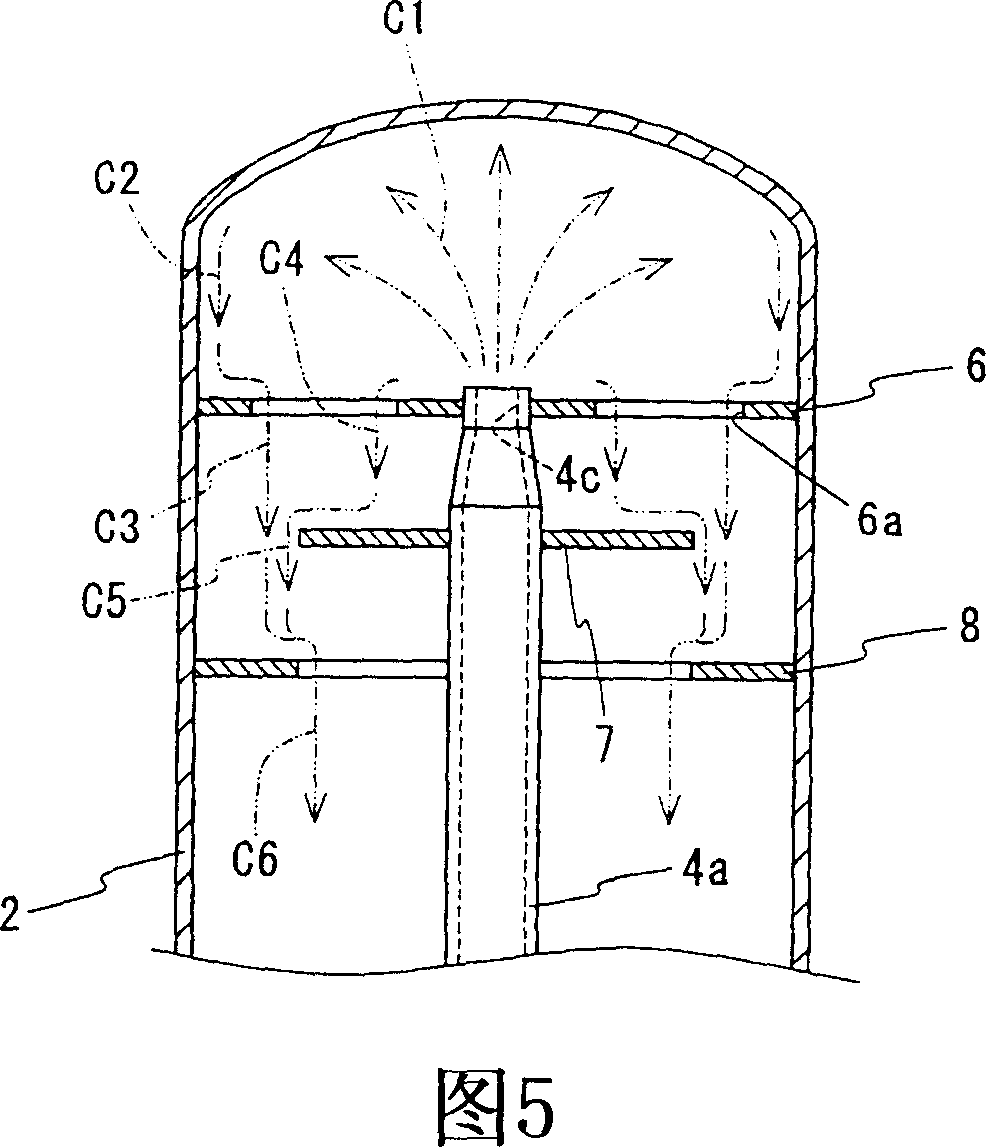

[0050] First, Embodiment 1 of the present invention will be described with reference to FIGS. 1 to 5 . Wherein, Fig. 1 is a sectional view of the brief structure of the oxygen dissolving device according to Embodiment 1 of the present invention; Fig. 2 is a sectional view along the arrow A-A direction in Fig. 1; Fig. 3 is a sectional view along the arrow B-B direction in Fig. 1; Fig. 4 is a cross-sectional view along the arrow C-C direction in FIG. 1; FIG. 5 is a schematic diagram of water flow in Embodiment 1.

[0051] As shown in FIGS. 1 to 4 , the oxygen dissolving device 1 of the present embodiment includes: a container 2 with a closed space; an oxygen supply mechanism 3 for supplying oxygen in the container 2; a pressure detector ( not shown in the figure); the water supply mechanism 4 for supplying water in the container 2; the drain pipe 5 for discharging the water inside the container 2; , 8; and a water level detector 9 that detects the water level in the container 2...

Embodiment approach 2

[0102] Next, Embodiment 2 of the present invention will be described with reference to FIGS. 6 to 8 . Fig. 6 is a cross-sectional view of the brief structure of the oxygen dissolving device according to Embodiment 2 of the present invention; Fig. 7 is a cross-sectional view along the arrow D-D direction in Fig. 1; Fig. 8 is a schematic diagram of water flow in Embodiment 2.

[0103] As shown in Figure 6, in the present embodiment, the oxygen dissolving device 20 has the oxygen supply mechanism 3, the water supply mechanism 4, the drain pipe 5 and the restrictor plates 6, 7, 8 in the oxygen dissolving device 1 of the above-mentioned embodiment 1. different, but the same structural parts as the oxygen dissolving device 1 are marked with the same symbols, and the detailed description thereof will be omitted.

[0104] As shown in Fig. 6 and Fig. 7, the oxygen dissolving device 20 of the present embodiment has: the above-mentioned container 2; an oxygen supply mechanism 21 for supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com