Bottom plate material for container

A technology for container floor and sheet material, applied in packaging, wrapping paper, lamination devices, etc., can solve the problems of perishability, moisture deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

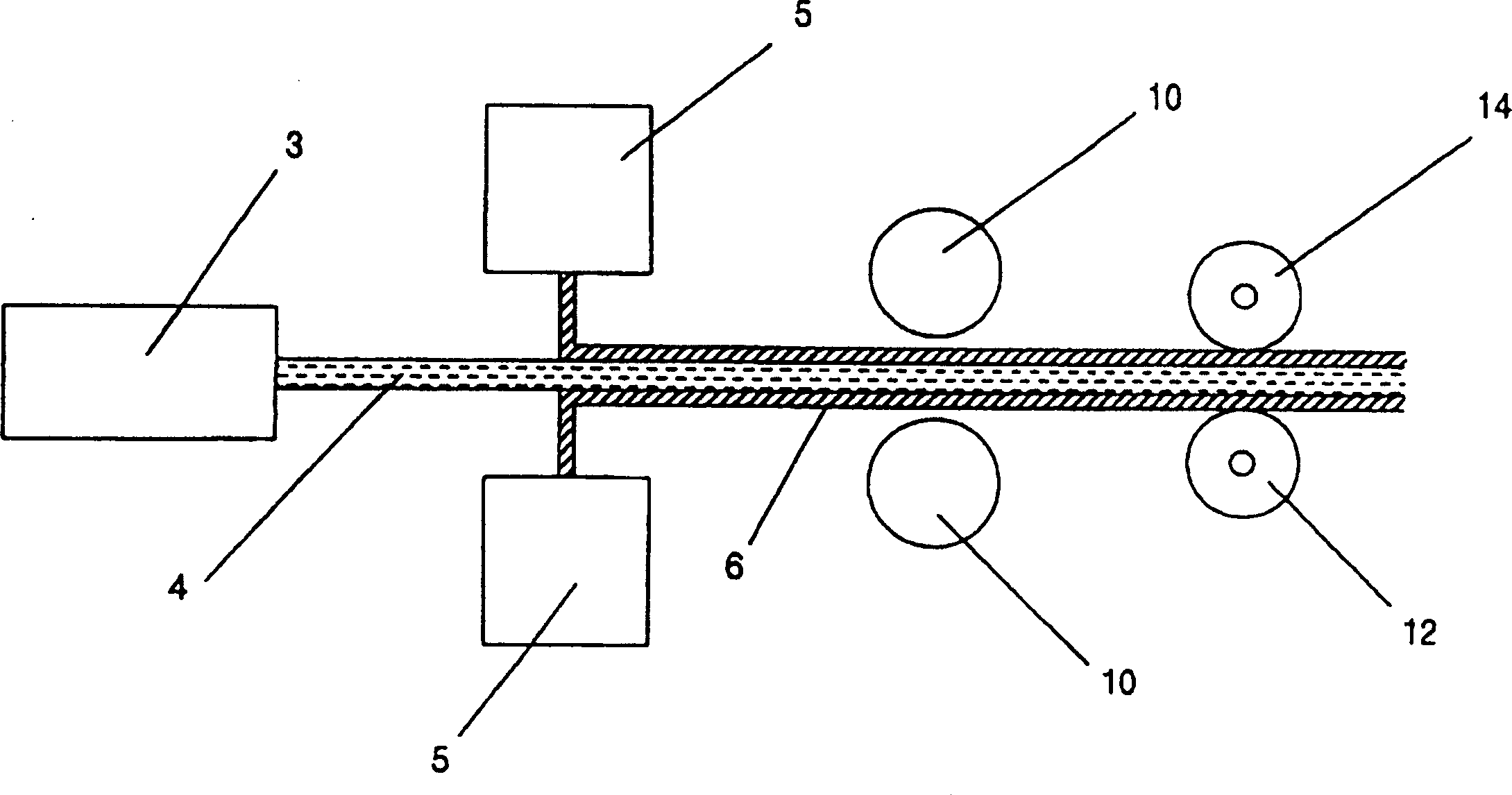

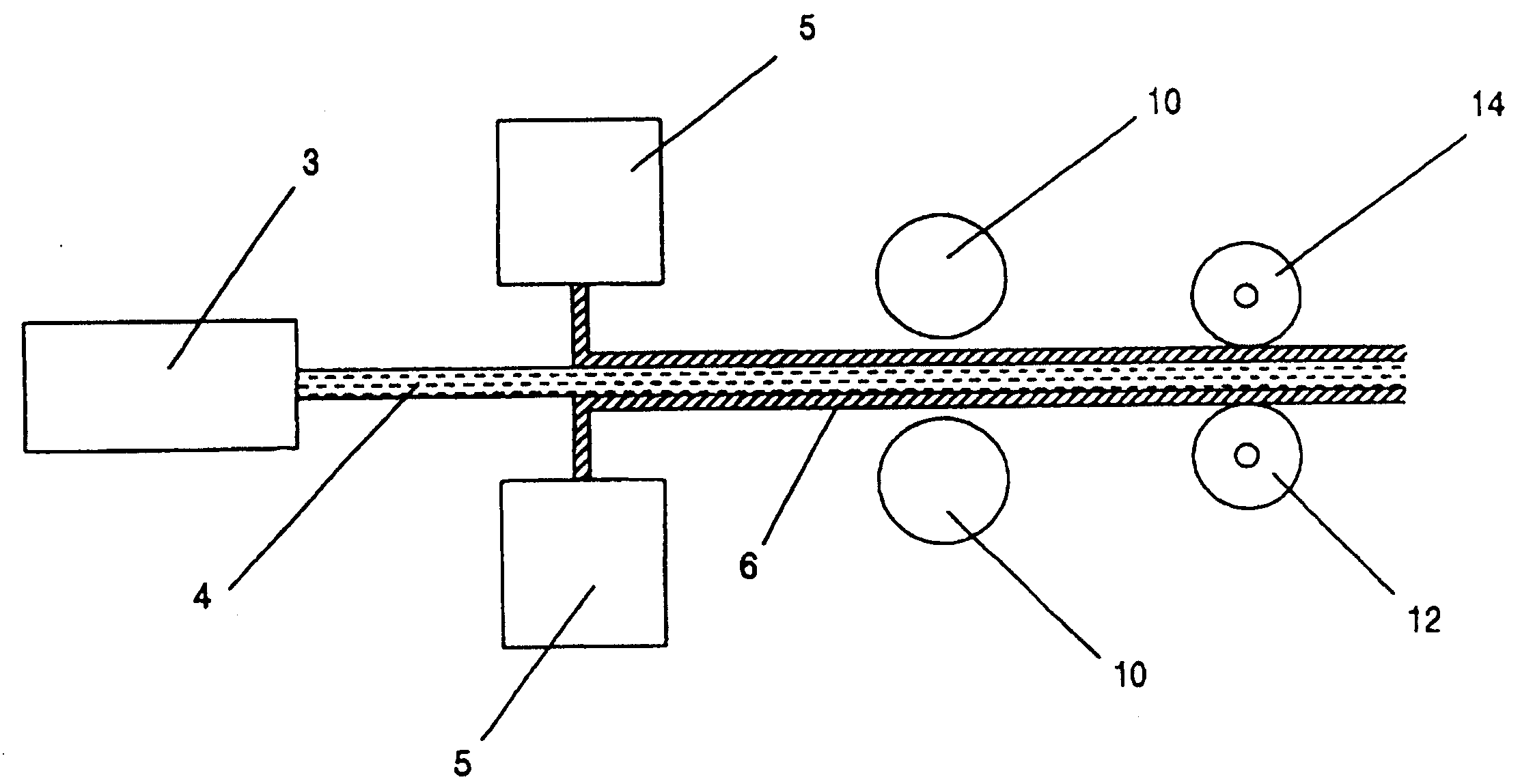

[0008] Embodiments of the present invention are described below with reference to the drawings.

[0009] Synthetic resins are ground into small particles, which are mixed with natural fiber materials and pressed into a certain mixture with an extruder. Here, the natural fibers consist of rice husks or sawdust.

[0010] That is to say, the diameter of synthetic resin is 0.1-0.3 mm, and the size of rice husk or sawdust is 20-50 meshes per square inch, which are dehydrated, dried, mixed, and then pressed into shape.

[0011] The preferred mixing ratio is 55%-75% of synthetic resin and 45%-25% of rice husk or sawdust.

[0012] In the surface binder used for surface bonding with the mixture, the synthetic resin accounts for 70% to 90%, and the additive accounts for 30% to 10%. The additive is made of at least one selected from glass fiber, carbonized fiber and needle-shaped structure filler.

[0013] In detail, synthetic resin composed of small particles and rice hulls or wood c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com