Method for producing sandy alumina through decomposing seeds in low concentration

An alumina, low-concentration technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, climate change adaptation, etc., can solve the problem that the decomposition technical conditions of alumina plants cannot meet the requirements of low-concentration decomposition, etc. achieve good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

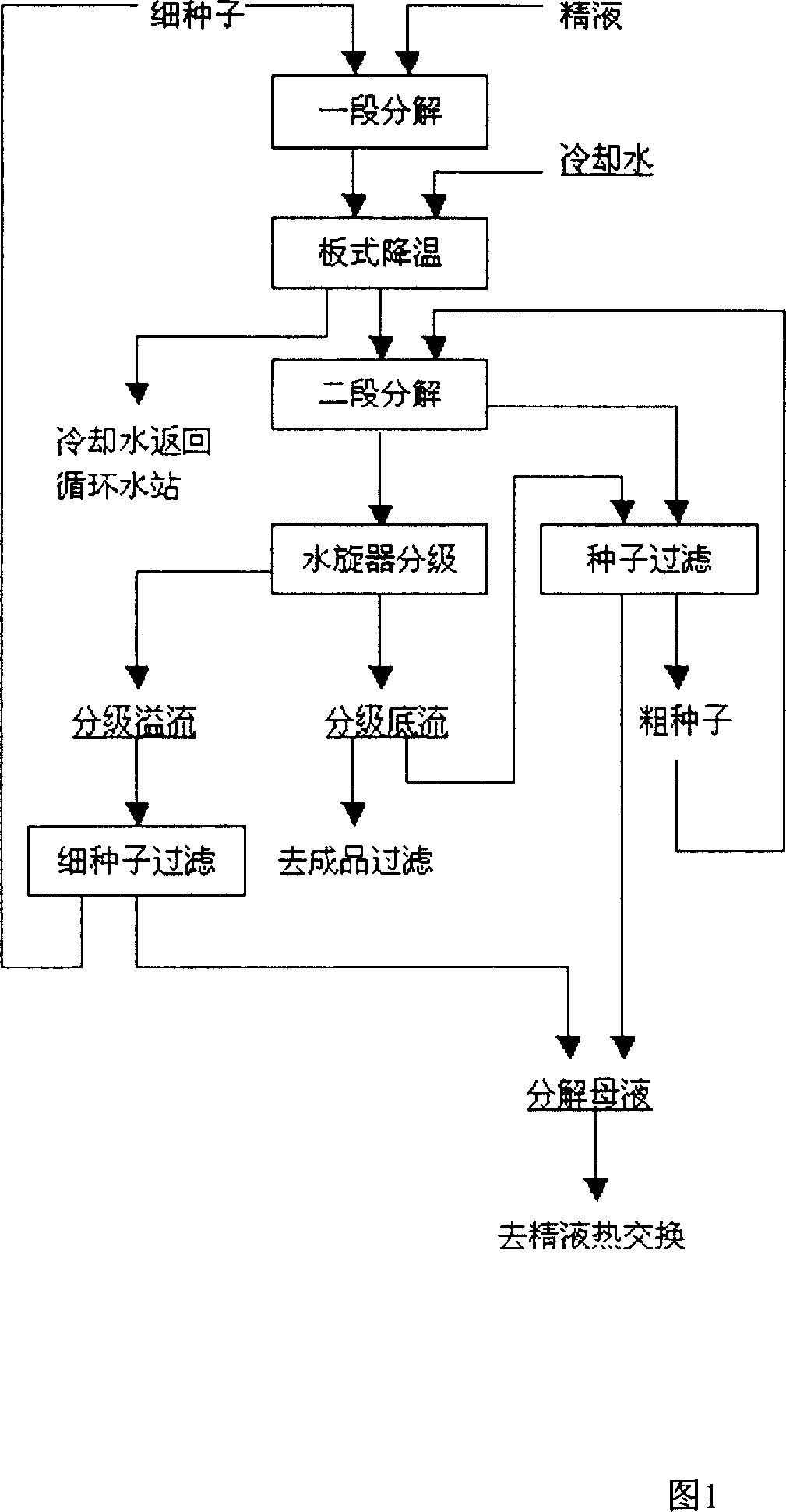

[0013] Embodiments of the present invention: Na in the semen sent from the settling workshop 2 o K Concentration 90~100g / l, Al 2 o 3 The concentration is 80-90g / l, mixed with the fine seeds of the plate and frame filter press according to the slurry solid content of 80-120g / l, and then added to the first stage of decomposition tank. The decomposition time of the fine seed agglomeration stage is 9 hours, and the first tank The temperature is 71°C, the solid content in the first tank is 80-120g / l, and the final decomposition temperature is 49°C. Then the temperature is lowered to 60°C through a wide channel plate heat exchanger, and the cooled aluminum hydroxide slurry enters the second stage for decomposition. The second stage is the crystal growth stage, and the decomposition time is 39 hours. The solid content of the tank is 300-400g / l, and the final decomposition temperature is 49°C. A hydrocyclone classifier is installed on the rear section of the second decomposition t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com