Air-supplying motor equipment for drying machine

A technology for blowing motors and fixing devices, which is applied in the direction of electromechanical devices, pump devices, machines/engines, etc., and can solve problems such as insufficient rotation frequency, reduced air supply capacity, and weak strength, so as to ensure strength and prevent air supply capacity Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail in conjunction with accompanying drawing and embodiment:

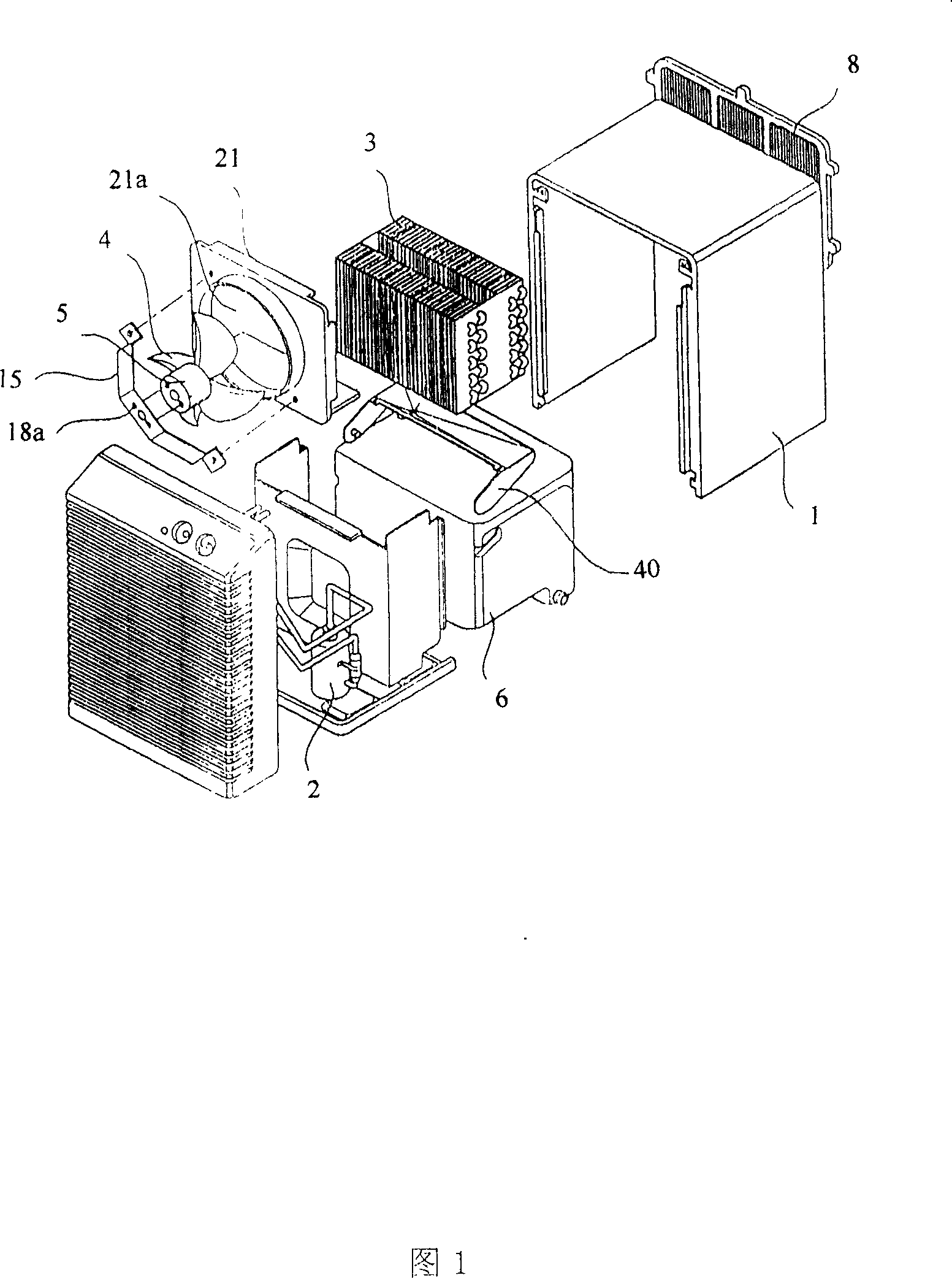

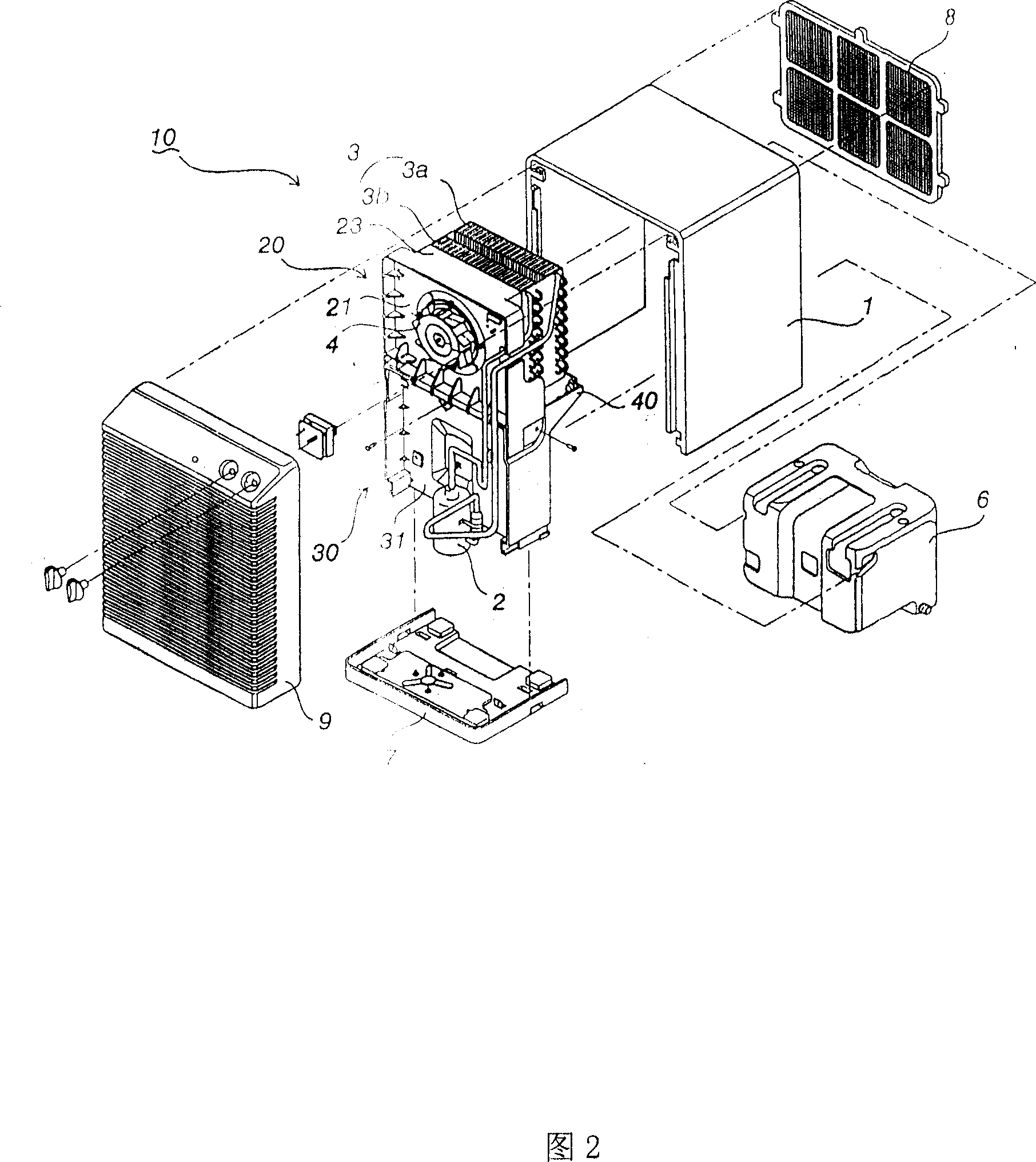

[0032] As shown in Figure 2, the drying machine of the present invention has a casing in which various devices can be installed, the casing is connected to the chassis at its lower part, and the side of the suction port on the back side of the casing is set as a filter that can purify the indoor air. In addition, the side of the air outlet at the front end is assembled into a guide grille.

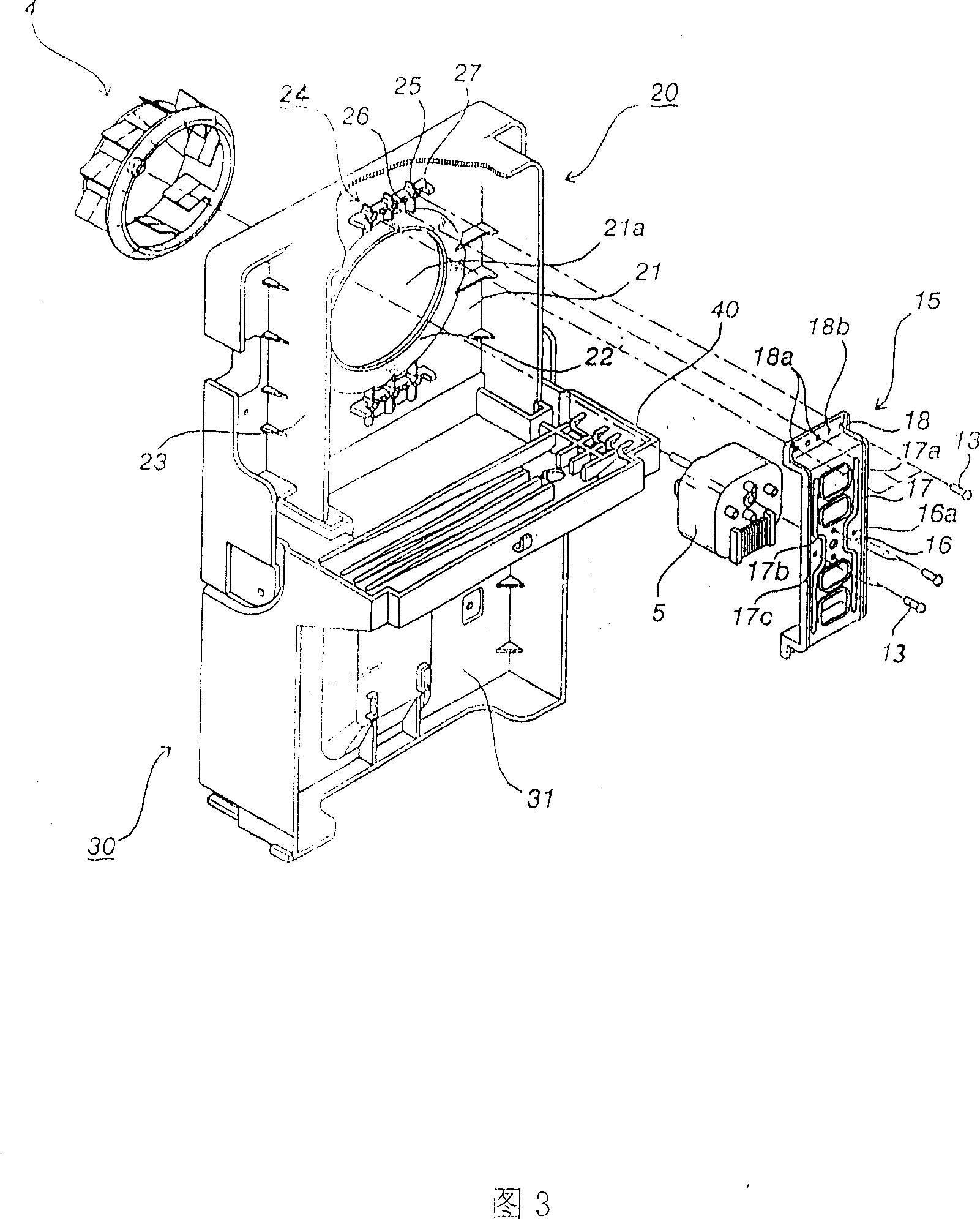

[0033] Inside the casing 1, there is a compressor 2 that compresses and circulates the refrigerant, a heat exchanger 3 that uses an evaporator 3a and a condenser 3b to form indoor air heat exchange for dehumidification, and a heat exchanger located behind the heat exchanger 3. The fan 4 used to force the air flow, and the water tank 6 located on the lower side of the heat exchanger 3 to concentrate the condensed water, the above are the structures of various equipment insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com