Electric four-way change valve

An electric reversing and moving block technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of large refrigerant flow resistance, incomplete reversing valve reversing, and gas leakage, etc., to reduce work Conditions and costs, stable, accurate and complete commutation, and the effect of solving internal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

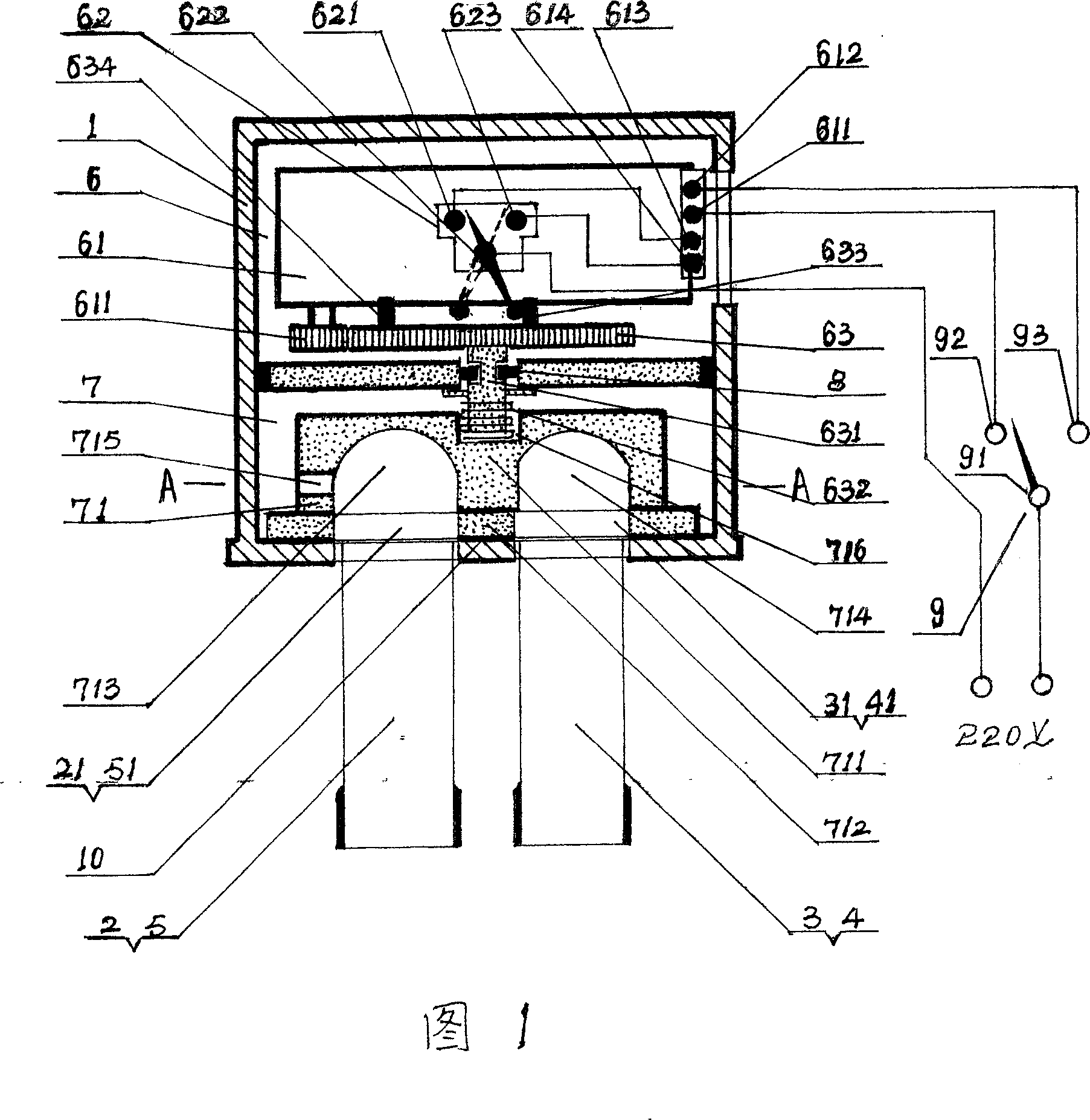

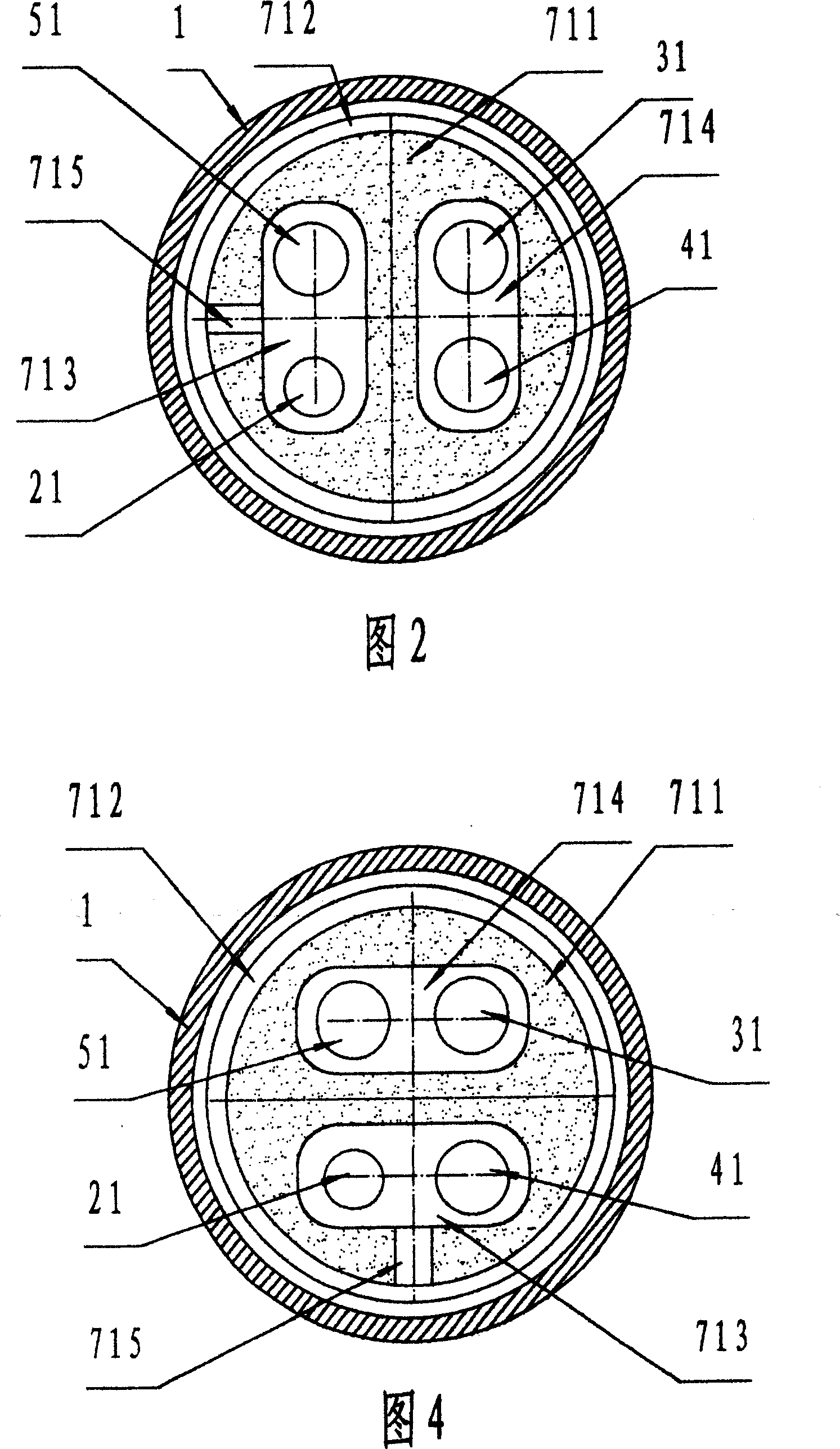

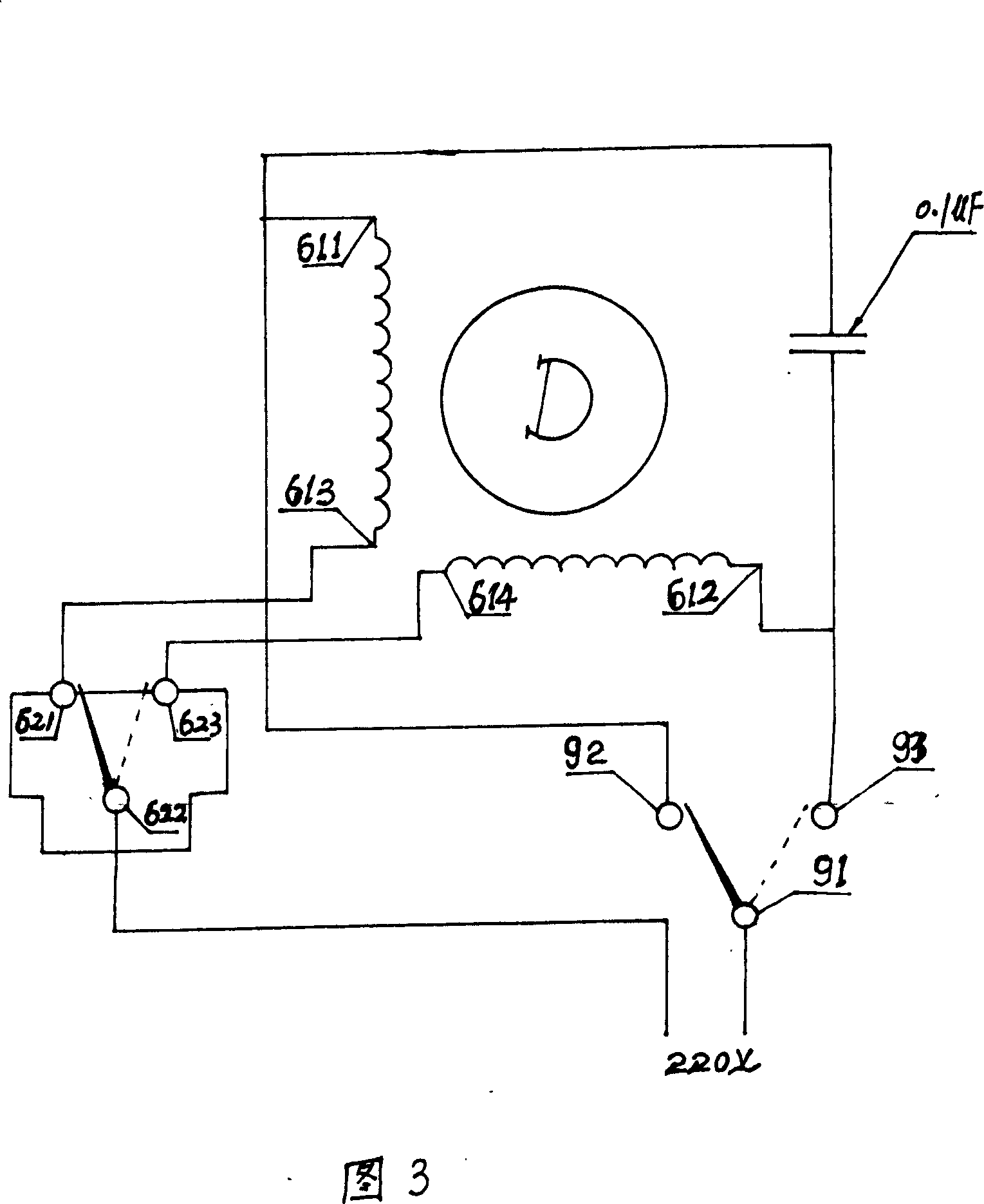

[0016] Referring to Figures 1-3, the specific structure of the present invention is reflected. In this embodiment, the valve body 1 is made of high-quality H68 brass or red copper die-casting, and the high and low pressure connecting pipes (2, 3) and the indoor and outdoor connecting pipes (4, 5) It is made of high-quality red copper. The inner cavity of the valve body 1 is divided into two sealed chambers by a ceramic partition, one is the control chamber 6, and the other is the execution chamber 7. In the control chamber In chamber 6, there is a motor 61, a control switch 62, and a toothed disc 63. The motor 61 adopts an AC220V42TYJ-F type motor with a rotating speed of 15 turns / min and a power of 2-5W. The output shaft teeth 611 of the motor and the toothed disc 63 Mesh to drive the toothed disk to rotate, the rotating shaft 631 of the toothed disk extends into the execution chamber 7 through a sealing ring 8, the rotating shaft 631 of the toothed disk is made of ceramics, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com