Method and apparatus for estimating performance of anion-exchange resin and condensed-water desalting device

A technology of ion exchange resin and exchange resin, which is applied in the direction of organic anion exchanger, ion exchange water/sewage treatment, ion exchange mediation/control, etc. It can solve the problem of inaccurate evaluation of the performance of anion exchange resin and the reduction of reaction rate of cation exchange resin And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

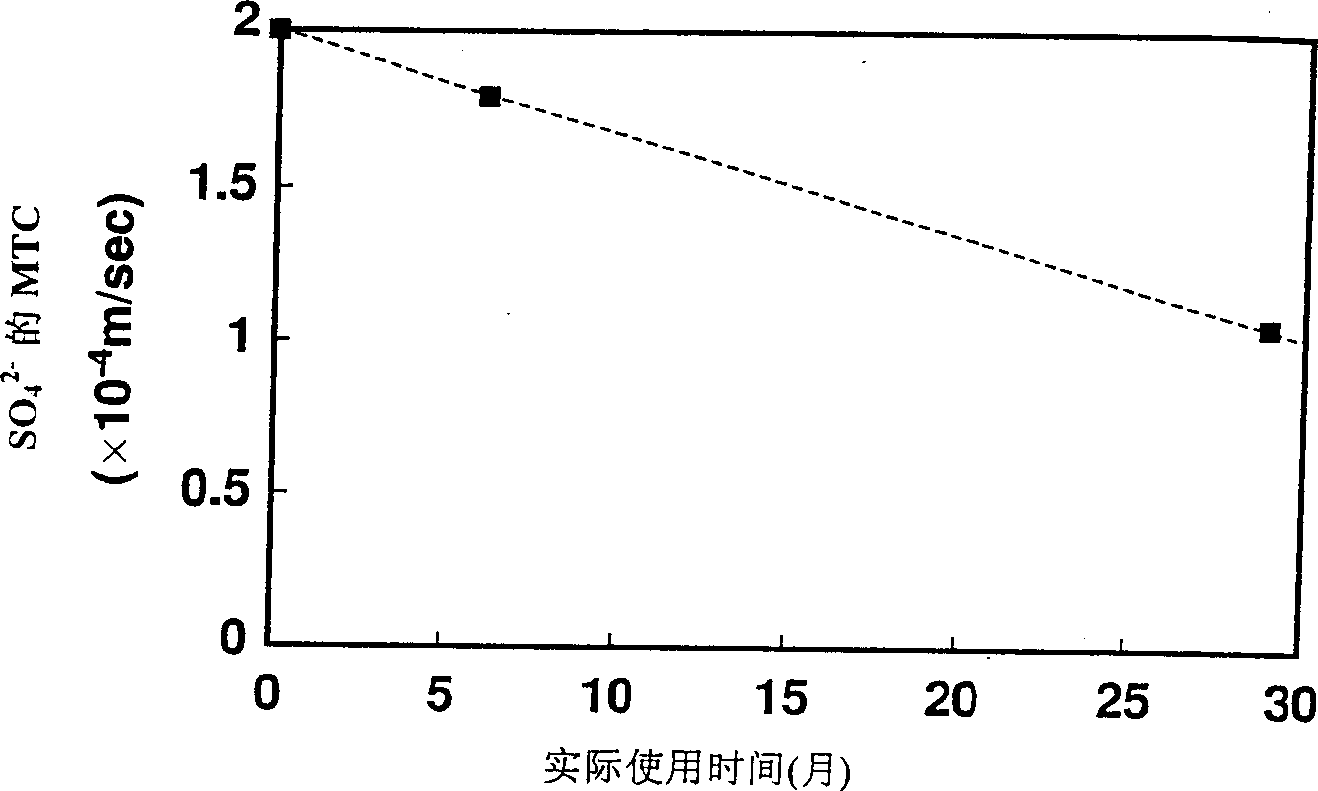

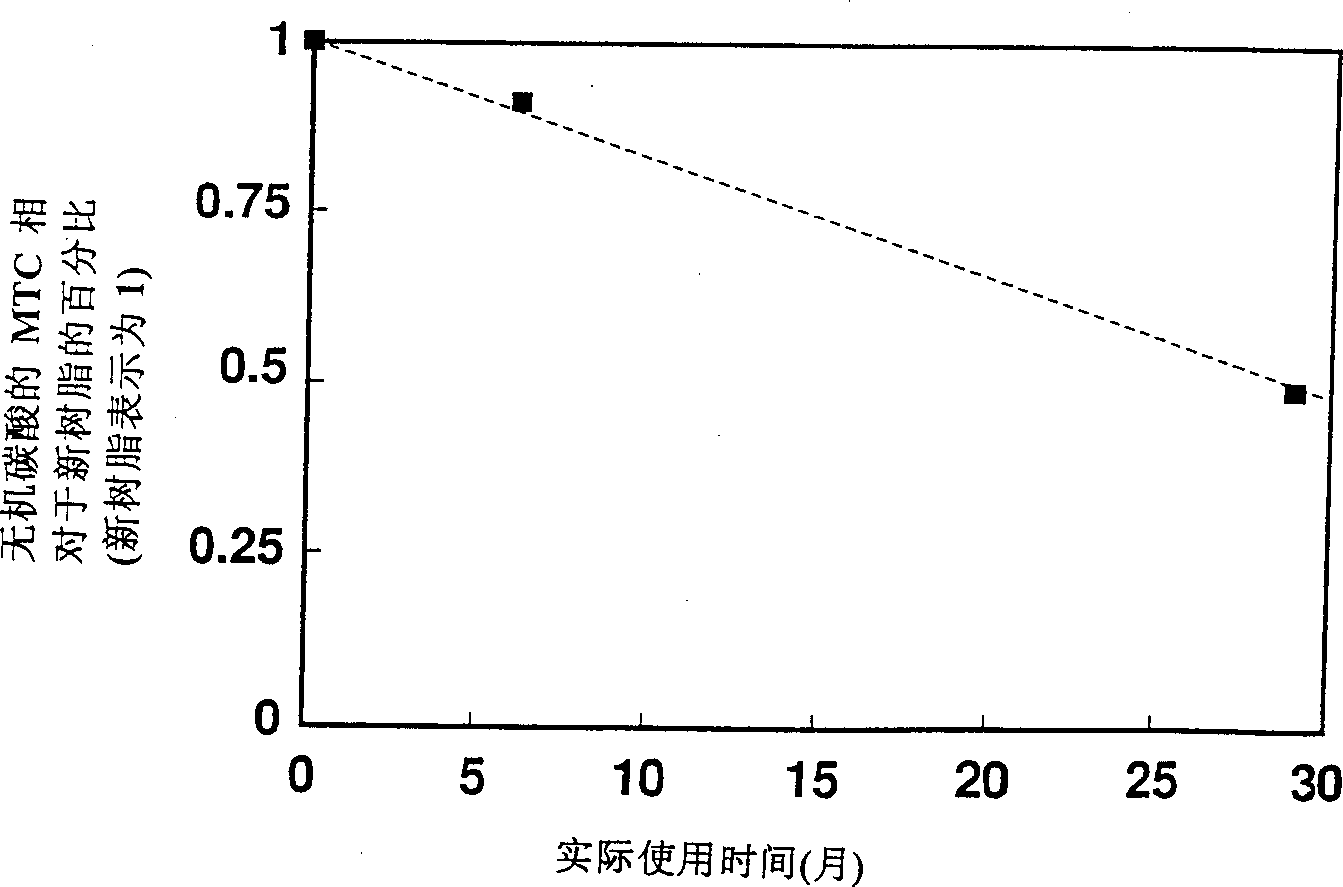

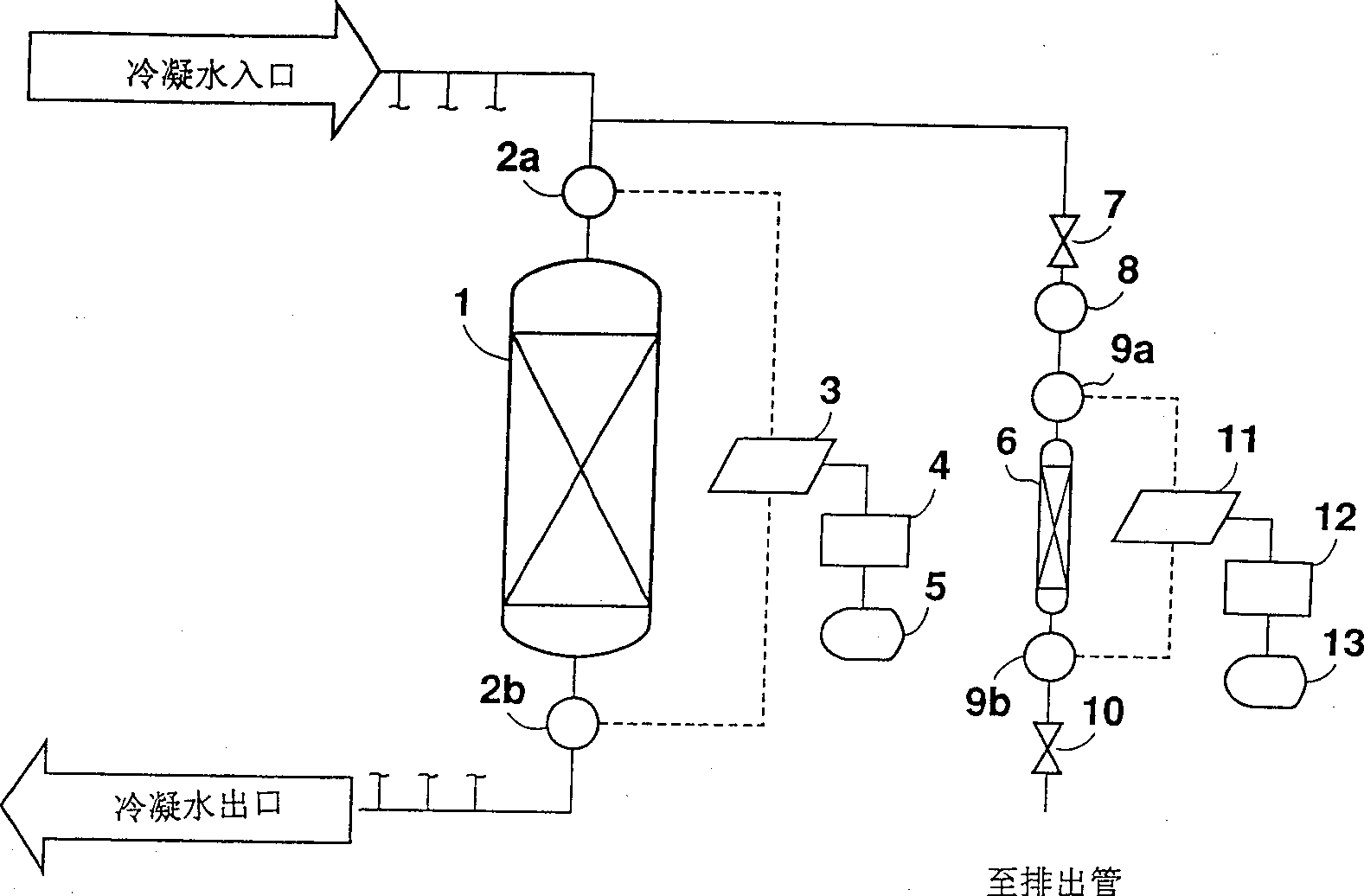

[0037] The concentration of inorganic carbonic acid in the water at the inlet and outlet of the desalter vessel for the condensate desalination system in a nuclear power plant was measured using an electronic conductivity sensor with a gas permeable membrane. Inorganic carbonic acid MTC value of new anion exchange resin (the resin in the container of the working demineralization device, the resin is replaced immediately after the demineralization operation is filled with a new anion exchange resin start), some types of resin ①Used in the working demineralizer container for about six months and regenerated, while some resins ②Used in the working demineralizer container for two years and five months and regenerated, they were measured and determined these MTC values compared with the new resin The ratio of MTC values. Some measurement conditions are shown below. The results obtained are shown in Table 3. (1) The height of the ion exchange resin layer in the container of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com