High-strength hollow building block of concrete and its production and application methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

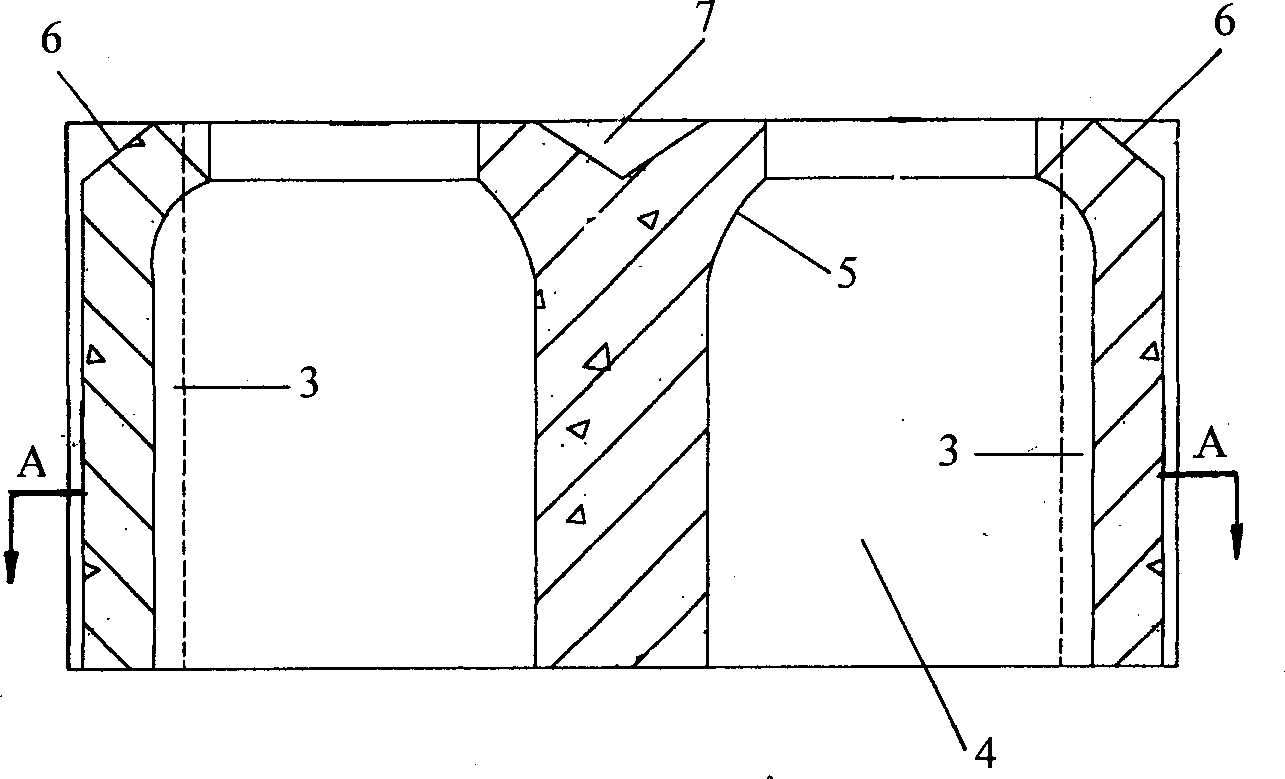

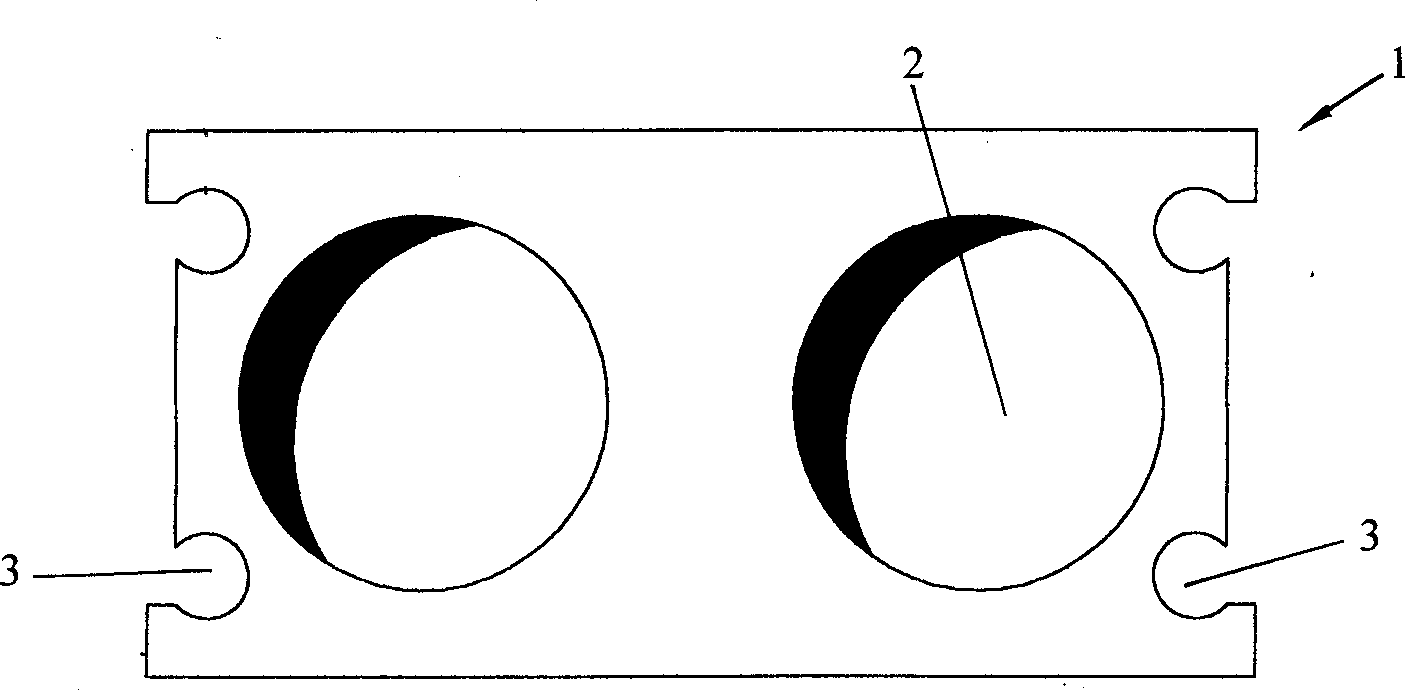

[0028] The concrete hollow block 1 is provided with a hole 2 on the block 1, the shape of the lower part 4 of the hole is a cylinder, and the shape of the top of the hole is a top ring with an arc 5; the position of the hole 2 is aligned with the block 1; The two sides of the end of the block 1 are respectively provided with two tenon grooves 3; the two sides 6 of the top of the block are inclined inwardly, and a groove 7 is provided in the middle of the top surface of the block. The diameter φ of the cylinder in the lower part of the hole is 130 mm, and the top of the hole is a top ring body with an arc 5, and the radius R of the arc 5 is 38 mm. The shape of the cross section of the groove 7 in the middle of the top surface of the block 1 is triangular or semicircular.

Embodiment 2

[0030] Production method of high-strength concrete hollow block:

[0031] 1. Use the "Shuangfei powder" pulverizer to crush the clean and mud-free stone surface sand into ultra-fine powder for later use. 2. Mix 1 part of superfine powder and 2 parts of stone surface sand with a mixer to make stone surface sand for later use. 3. Mix 1 part of stone sand with a particle size of 3 to 5 mm and 2 parts of stone sand with a particle size of 6 to 10 mm to form fine gravel. 4. According to the weight ratio, cement: stone surface sand: fine gravel: water = 1: 2.5: 4.5: 0.3, use the computer system to control the ingredients and just stir.

Embodiment 3

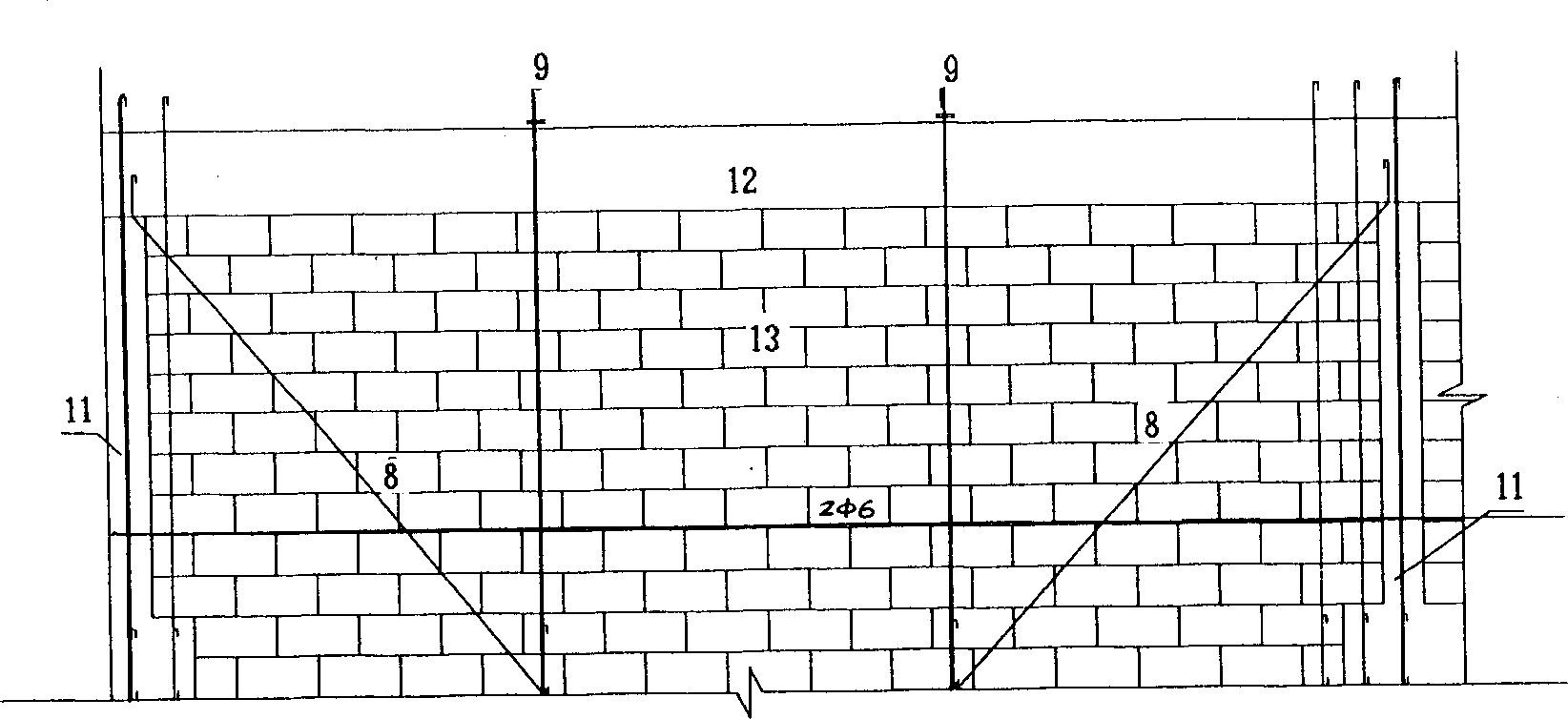

[0033] Such as image 3 , Figure 4 As shown, the structure of the block wall without door and window openings; Figure 5 , Image 6 As shown, there is a structure of block walls with door and window holes. From which it is clearly reflected that the construction method of the present invention has the following characteristics: 1. the holes of the upper and lower floor blocks are centered, and the reinforced concrete construction column 11 is located at the node; 2. around the reinforced concrete construction column 11, the block hole 10 ③Put the prestressed tendons 9 in the middle of the wall and the block holes on both sides of the door and window openings and apply prestressed; ④Set the diagonal stays 8 in the holes of the wall to pull the reinforced concrete of the outer wall. A ring beam 12 is arranged on the upper part of the structural column 11 and the block wall 13 . Thereby improving the anti-seismic performance of the block building, effectively avoiding the da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com