Rotary dryer

A rotary drying and rotary technology, used in non-progressive dryers, dryers, drying solid materials, etc., can solve problems such as difficulty in implementation, increased cost, and longer drum length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the device related to the present invention will be described in detail with reference to the drawings of the embodiments.

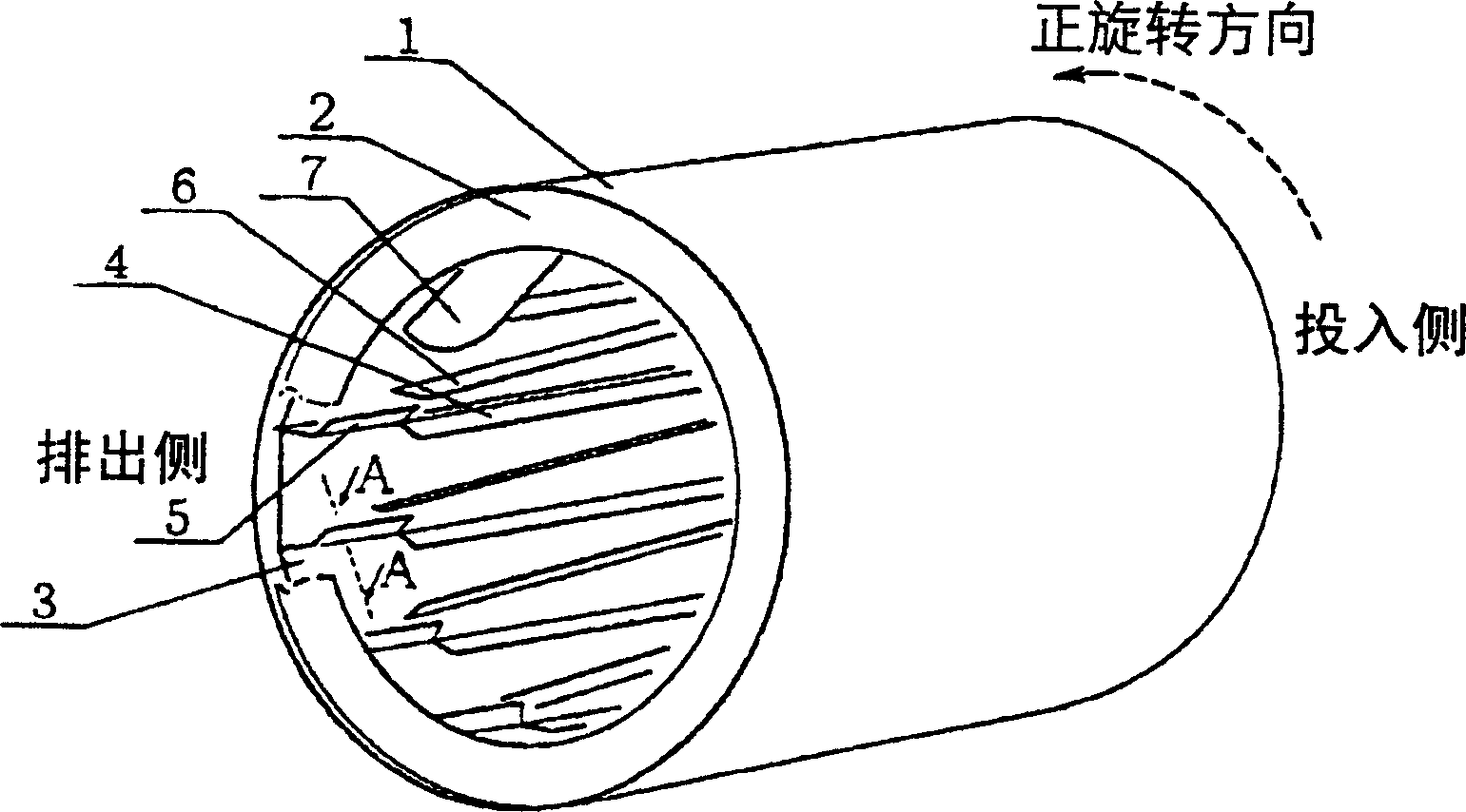

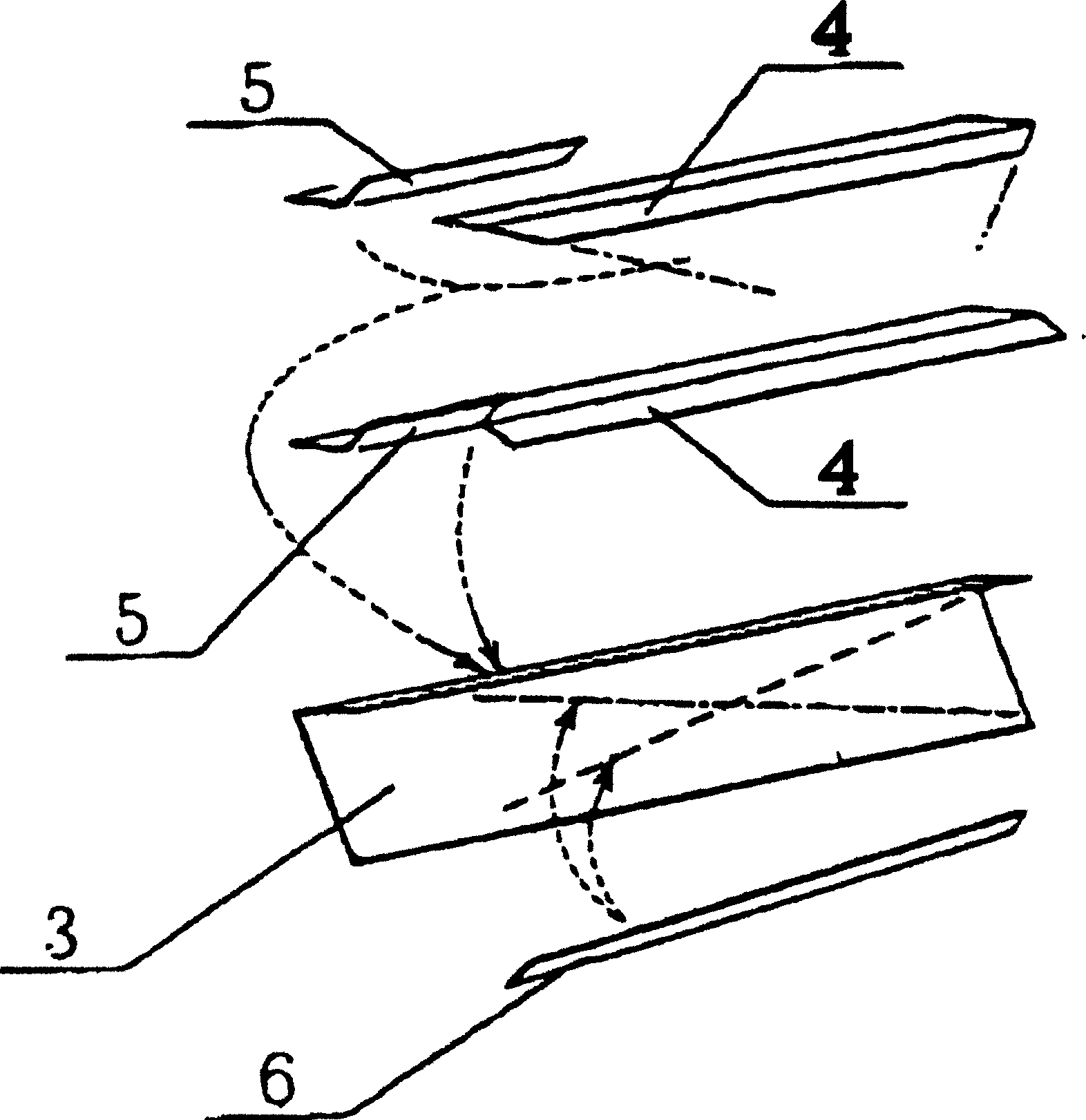

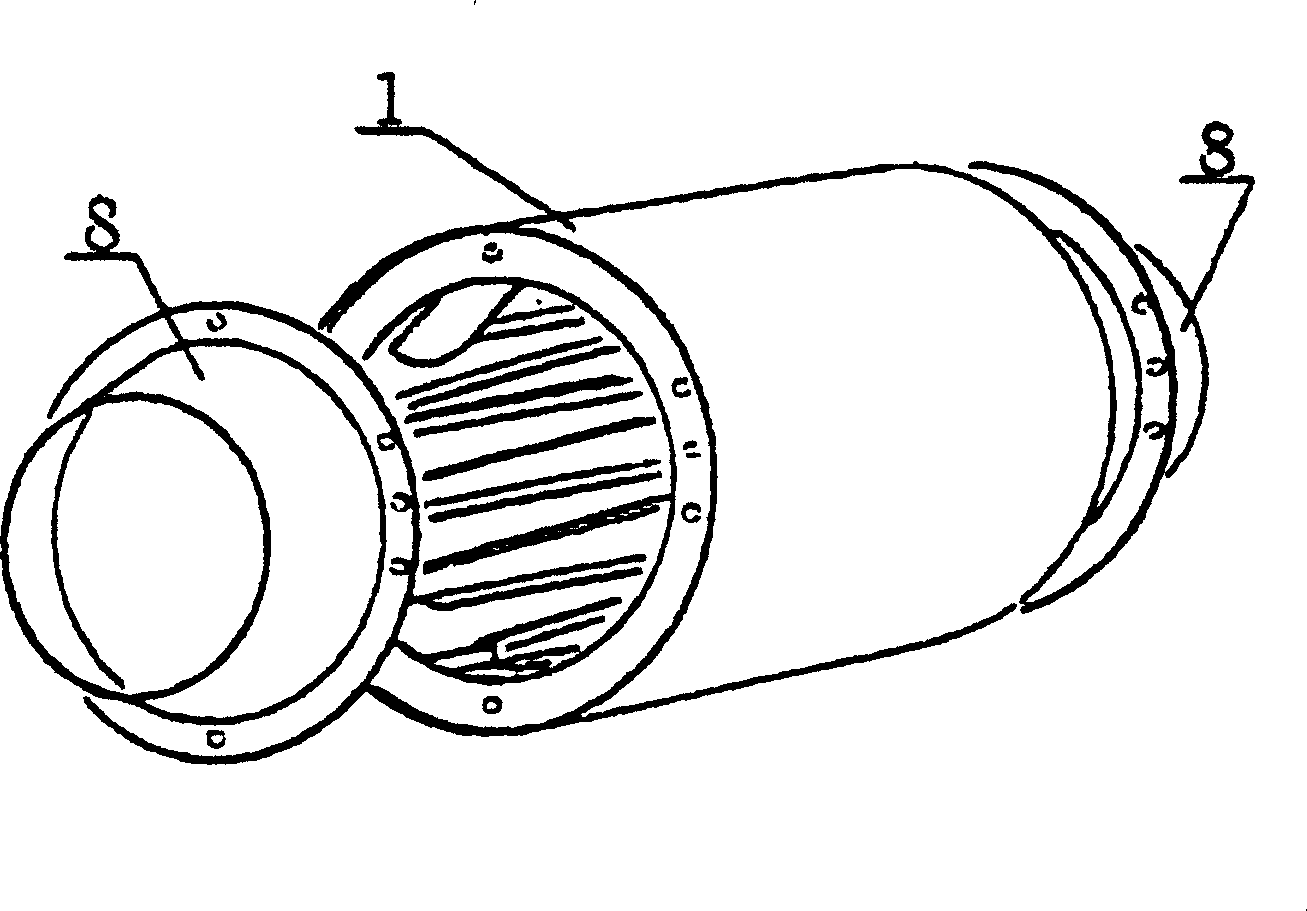

[0018] Figure 1 to Figure 3 Examples of inventions corresponding to claims 1 to 4 of the present invention are shown. At both ends of the outer cylinder (1) of the drum, the end plates (2) welded thereon are fixed, and further, a spacer (3) with a U-shaped or レ-shaped cross section is installed on the inner side of the outer cylinder. Both ends are fixed by end plates. On the spacer, a lifter (4) for forward rotation and a lifter (5) for reverse rotation are installed, and further, transfer ribs (6) are installed as required. Each part may be attached by any heat-resistant and firm method such as riveting, welding, or brazing. The material of each component is selected according to the characteristics of the object to be dried, especially the corrosion and heat resistance.

[0019] Simultaneously, the cross-section of the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com