Microcomputerized automatic control system for oil and gas well drilling throttling pressure

An automatic control system and throttling pressure technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems that are not suitable for continuous operation and cannot improve the control accuracy, and achieve the effect of precise control function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

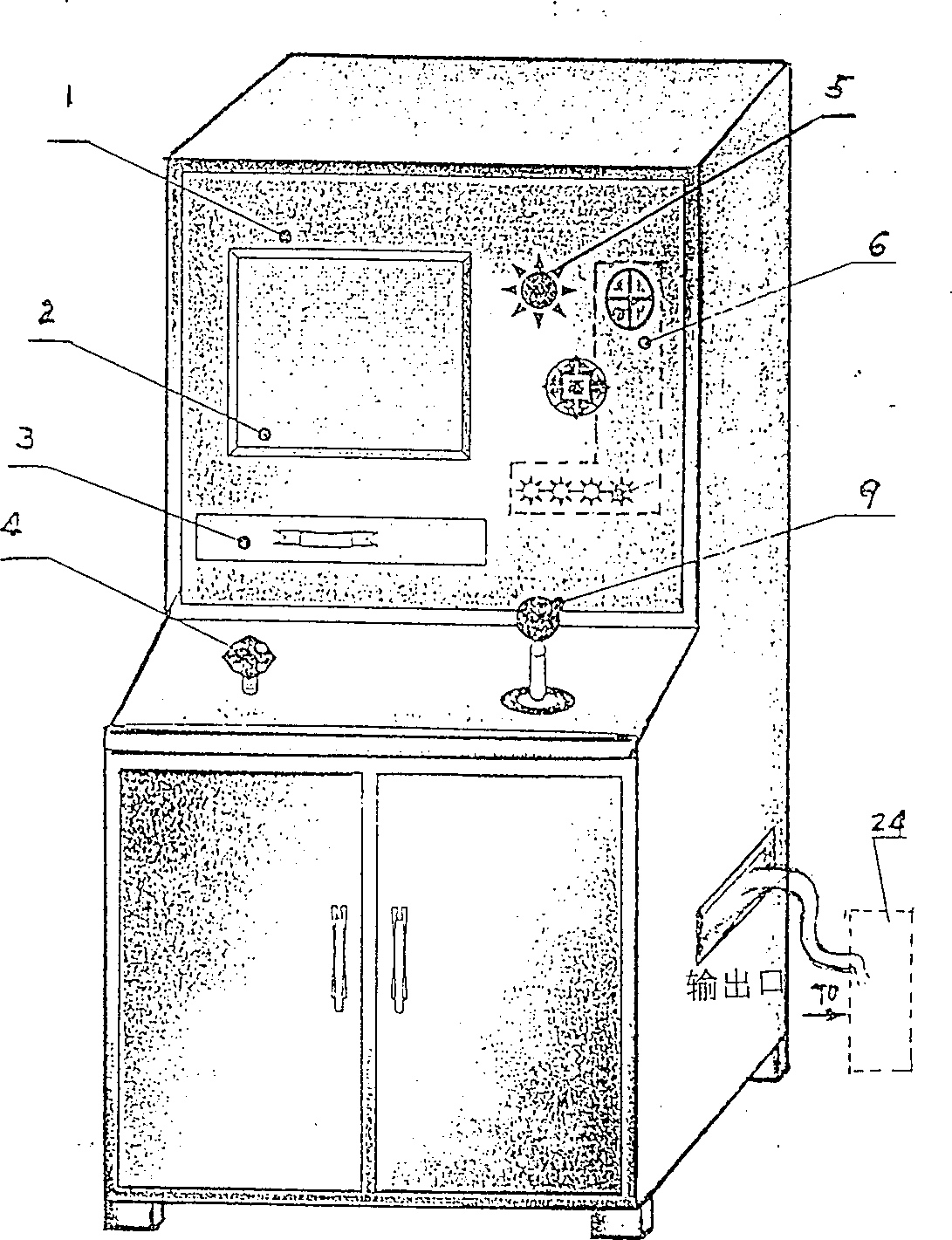

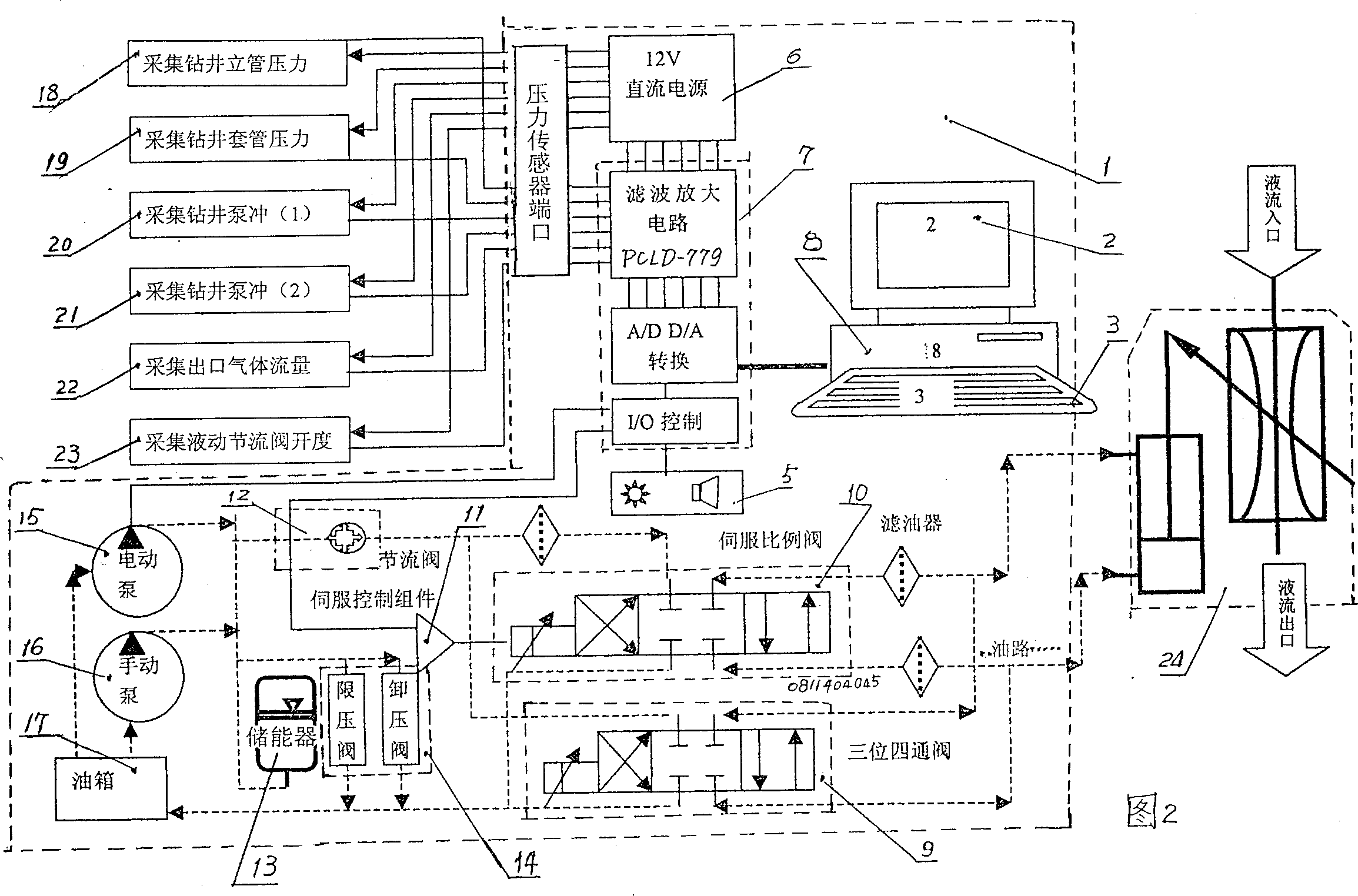

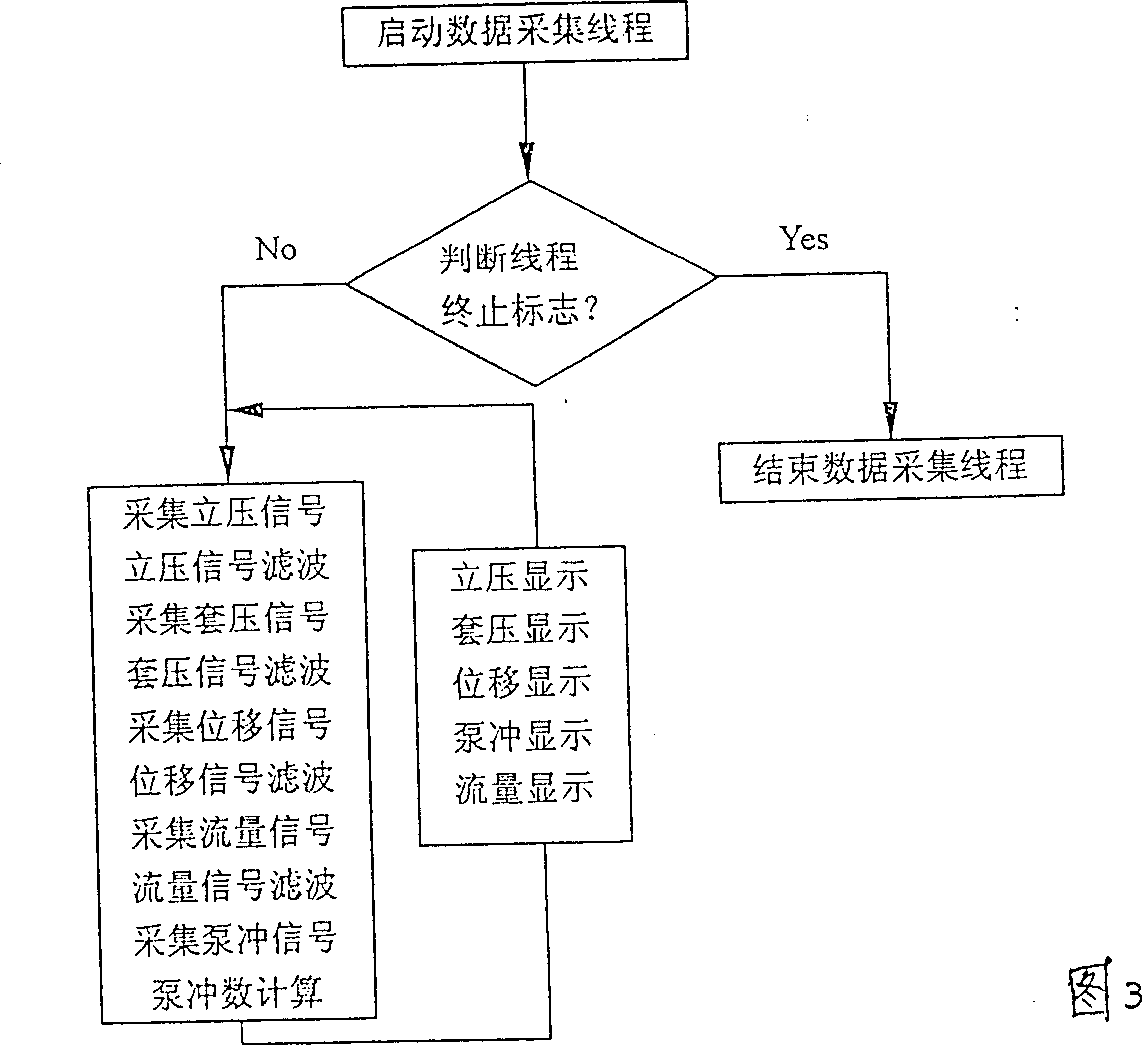

[0017] refer to figure 1 , showing the outline drawing of the main cabinet of the oil and gas drilling throttling pressure microcomputer automatic control device according to the present invention, 1 is the cabinet shell, and its front panel is provided with a computer display 2 and a keyboard box 3, and there are sound and light alarm holes 5 on the side of the panel As well as the power switch and indicator light part 6, a throttle valve knob 4 is provided on one side of the cabinet table, which is connected to the throttle valve 12 inside the cabinet, and a three-position four-way valve 9 is provided on the other side; with reference to Fig. 2, the present invention is shown The schematic diagram of the connection relationship of each component in the control system, 10 in the figure is a servo proportional valve, which is connected to the servo control component 11, and in the oil circuit controlled by oil pressure, the throttle valve 12 is respectively connected to the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com