Photoelectric conversion characteristics testing method and equipment for photoelectric switching equipment

A technology for photoelectric conversion and testing methods, which can be used in the testing of machine/structural components, optical instrument testing, and single semiconductor device testing, etc., and can solve problems such as difficulties and changes in output characteristics of stacked photoelectric conversion devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

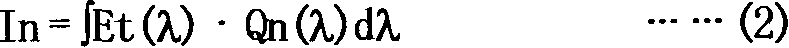

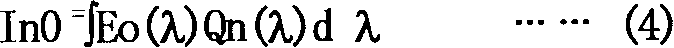

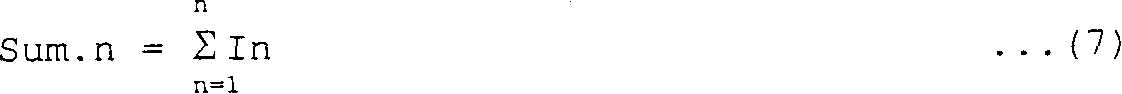

[0142] Use the following method to test the output characteristics of the photoelectric conversion device (sample) as the object to be tested outdoors with sunlight. In this case, it is three three-layer solar cell modules. The structure of each solar cell module is from light incident to one Starting from the side, the Pin junction using amorphous silicon as the i-type layer (hereinafter referred to as the top cell) and the Pin junction using amorphous silicon germanium as the i-type layer (hereinafter referred to as the middle cell) and the amorphous silicon germanium as the i-type layer are sequentially stacked. The Pin junction of the -type layer (hereinafter referred to as the bottom battery).

[0143] The module configuration of each 3-layer solar cell is, in which 5 cells with a size of 35 cm × 24 cm formed on a single stainless steel substrate, connected in series, supported on a support plate via bypass diodes, and form a surface protection layer . The external dimen...

example 2

[0170] Measure the output characteristics of the laminated photoelectric conversion device under the standard test conditions with the same method as Example 1, except that the laminated photoelectric converter as the object to be tested becomes an a-Si / c-Si double-layer solar cell module, wherein, The Pin junction (hereinafter referred to as a-Si cell) uses amorphous silicon as the i-type layer, and the Pn junction (hereinafter referred to as c-Si cell) uses single crystal silicon as the n-type layer. The incident sides were superimposed, and the filters used for standard cells were changed.

[0171] The double-layer solar cell module is a so-called high-reliability module. The size of the module is 95cm×55cm, and there are 15 battery strings of serial double-layer solar cells×3 parallel double-layer solar cells connected to each other. Each double-layer solar cell can The cells are formed on single crystal silicon wafers measuring 10cm x 10cm. When measuring the spectral se...

example 3

[0175] In Example 3, a stacked photoelectric conversion device (sample cell) is used as the object to be tested, and 10 a-Si / μc-Si double-layer solar cells are stacked in sequence from the light incident side, wherein each a-Si / μc- The structure of the Si double-layer solar cell is that the Pin junction (hereinafter referred to as a-Si cell) uses amorphous silicon as the i-type layer, and the Pin junction (hereinafter referred to as μc-Si cell) uses microcrystalline silicon as the i-type layer. With the method of the present invention, the existing fixed-light sunlight simulator uses a xenon lamp as a light source for testing. The 10 samples were numbered #3-1...#3-10.

[0176] The a-Si / μc-Si bilayer solar cell is a cell formed on a single stainless steel substrate with a size of 15 cm×15 cm, and the cell is in a single unit state before being connected in series or parallel. The effective radiation area of the solar simulator is 15cm×15cm. The temporal change rate of irra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com