Particle accelerator

A technology of particle accelerator and voltage multiplier, which is applied in DC voltage accelerators, X-ray tubes, discharge tubes, etc., and can solve problems such as damage to insulators, increase in outer diameter, and obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

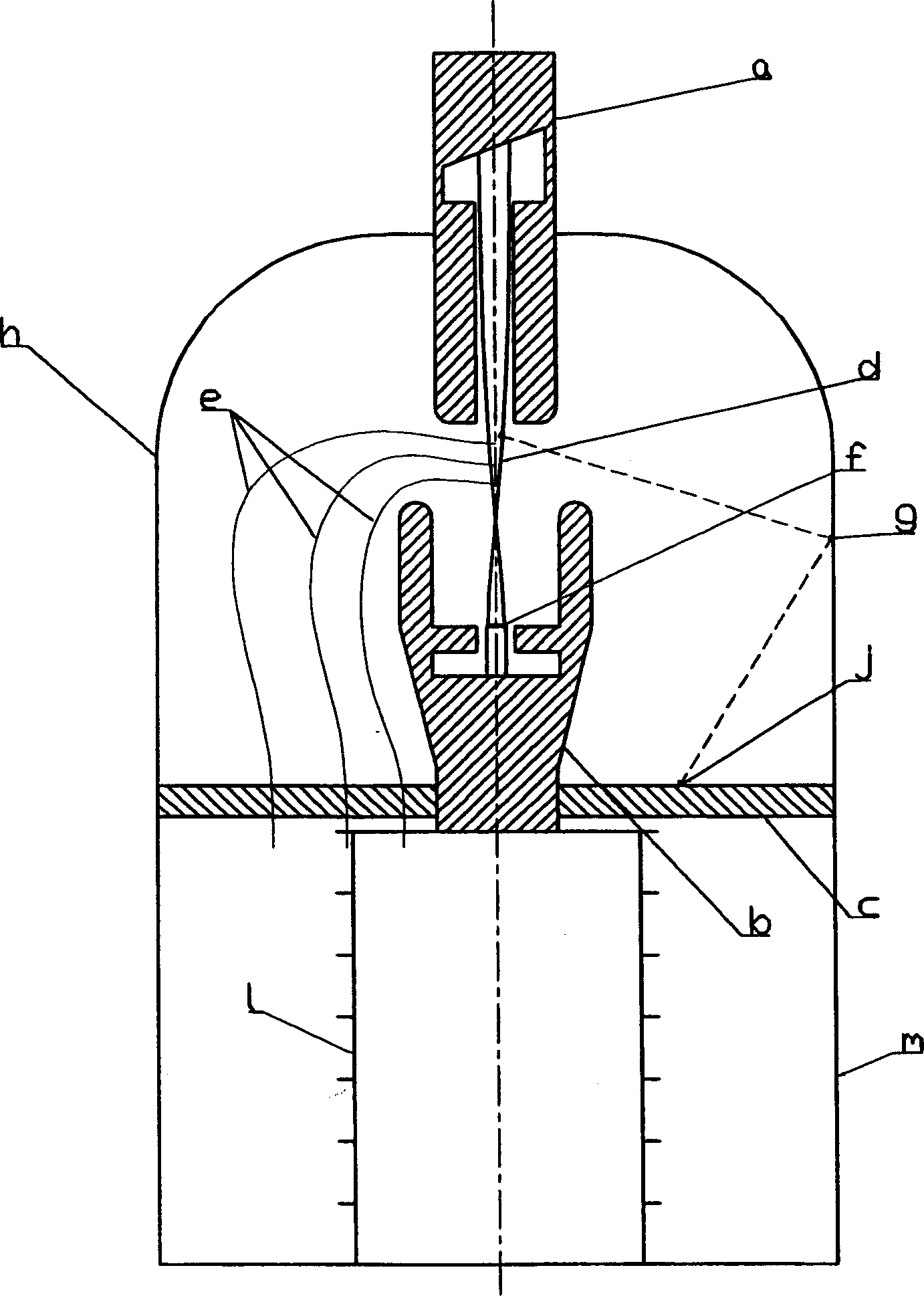

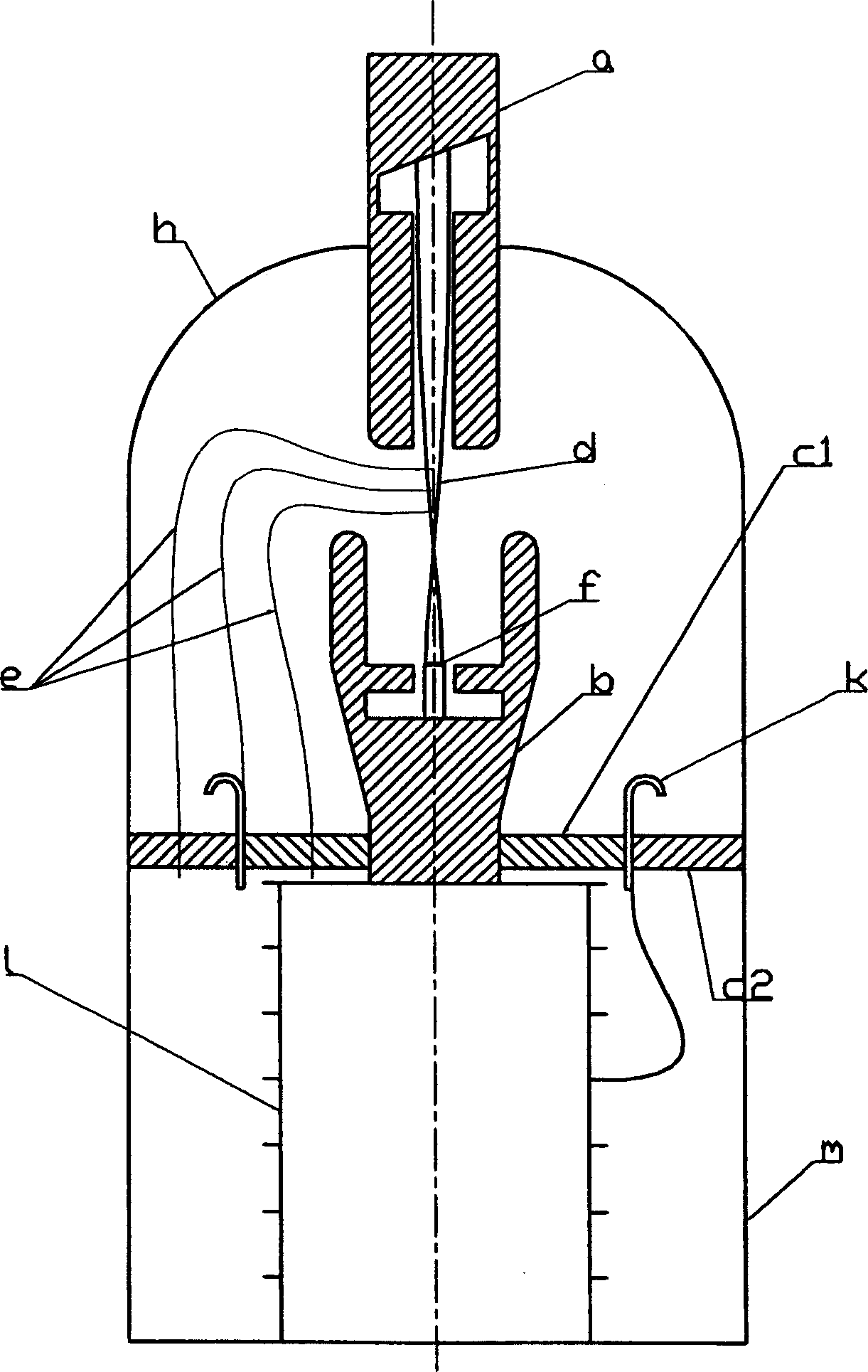

[0021] in Figure 6 An example of the voltage multiplier used in the device is shown in Figure 4c in. In particular, the multiplier includes 7 stages, and how each electrode k1 to k6 is connected to each stage of the multiplier is schematically illustrated.

[0022] As a result, the insulator is divided into as many parts as there are stages in the multiplier of the supply tube, exactly as Figure 5 The example is shown. The essential difference is that in the present invention, the voltage multiplier can be arranged in the space including the X-ray tube, which can greatly reduce the size of the component, especially the outer diameter. In other words, the voltage multiplier is encapsulated in an insulator.

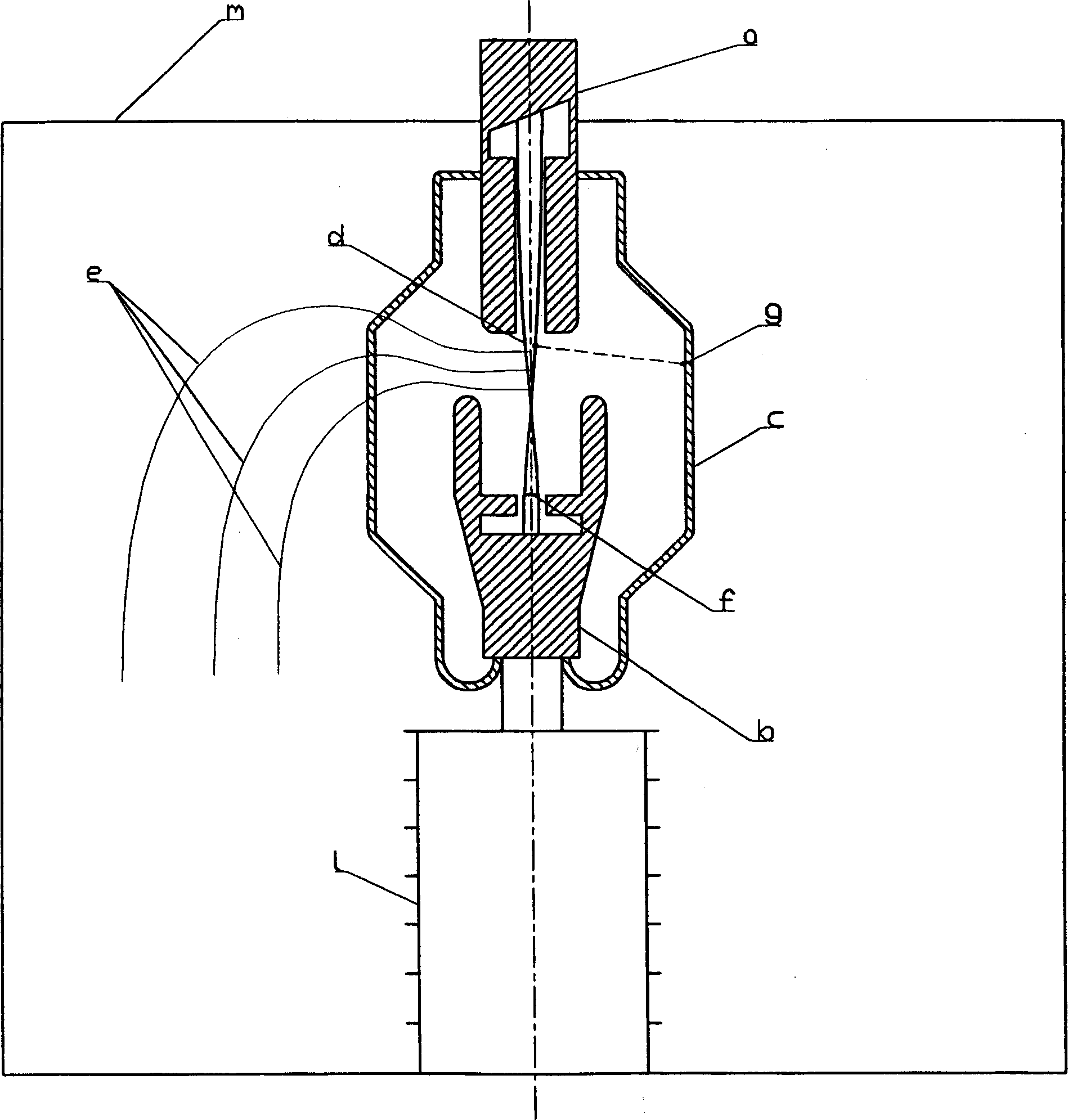

[0023] The reasons for the size reduction are compared image 3 with 6 Can be clearly seen. image 3 In represents the known solution, it can be seen that in order to reduce the electric field, the equipotential lines must be completely separated along the radius passing thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com