Monitor for electric arc welding machine

An arc welding machine and monitor technology, which is applied in the field of arc welding, can solve the problems of unsatisfactory work of the arc welding machine, lack of knowledge of welding methods, inability to overcome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] best practice

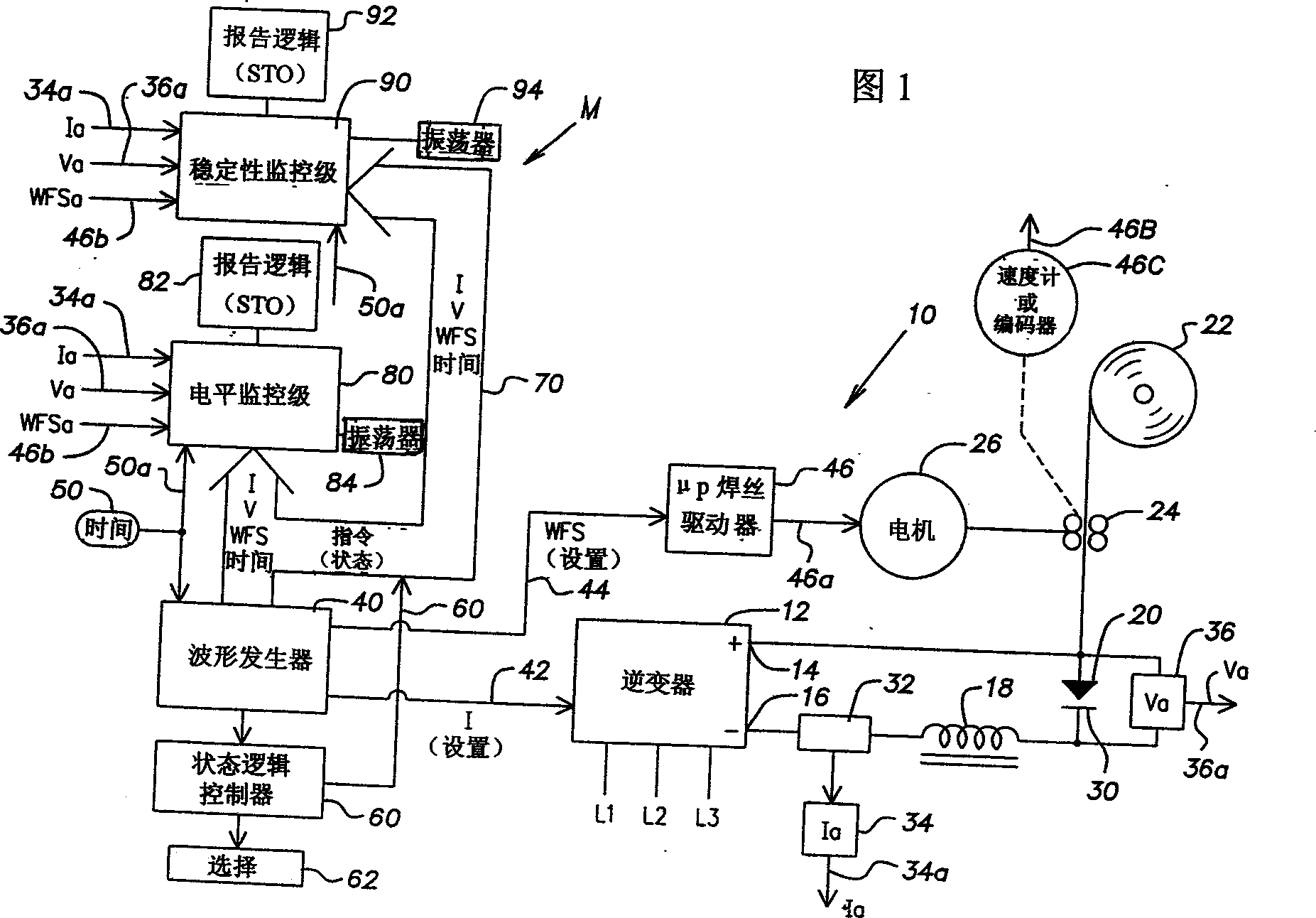

[0070]The preferred embodiment of the present invention and the application of the present invention will now be described with reference to the accompanying drawings. FIG. 1 shows a block diagram and flow diagram or program implemented using a standard on-board computer in an arc welder 10. As shown in FIG. In fact, welder 10 is an inverter-based Energy Wave arc welder sold by Lincoln Electric Company of Cleveland, Ohio, USA. The welder 10 includes three-phase electrical inputs L1 , L2 , L3 leading electrical current to a power source 12 according to standard techniques. An onboard computerized controller operates the inverter base power supply to produce a positive potential at terminal 14 and a negative potential at terminal 16 . The selected arc welding method is implemented by introducing a selected predetermined waveform to the actual welding circuit, which is shown with a standard filter inductor 18 . The welding machine A performs an arc weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com