Electromagnetic filter method for removing iron element from aluminium-silicon alloy

An aluminum-silicon alloy and electromagnetic filtration technology, applied in the field of metallurgy, can solve problems such as complex process, low removal efficiency, and singleness, and achieve the effects of simple process, improved cleanliness, and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

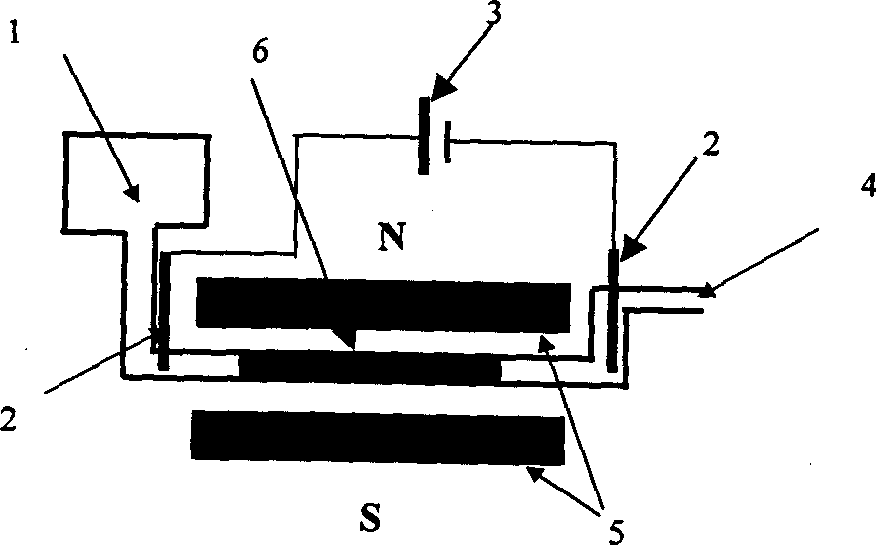

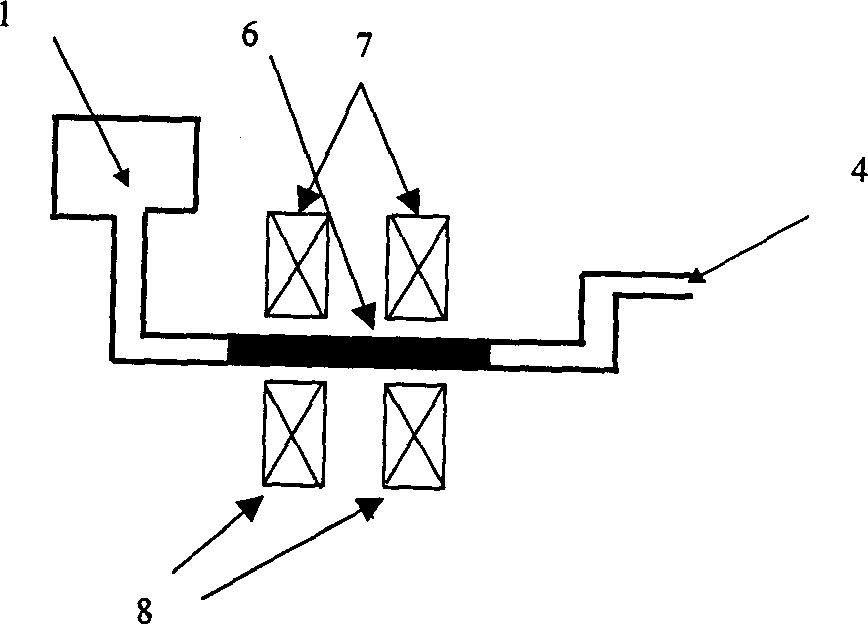

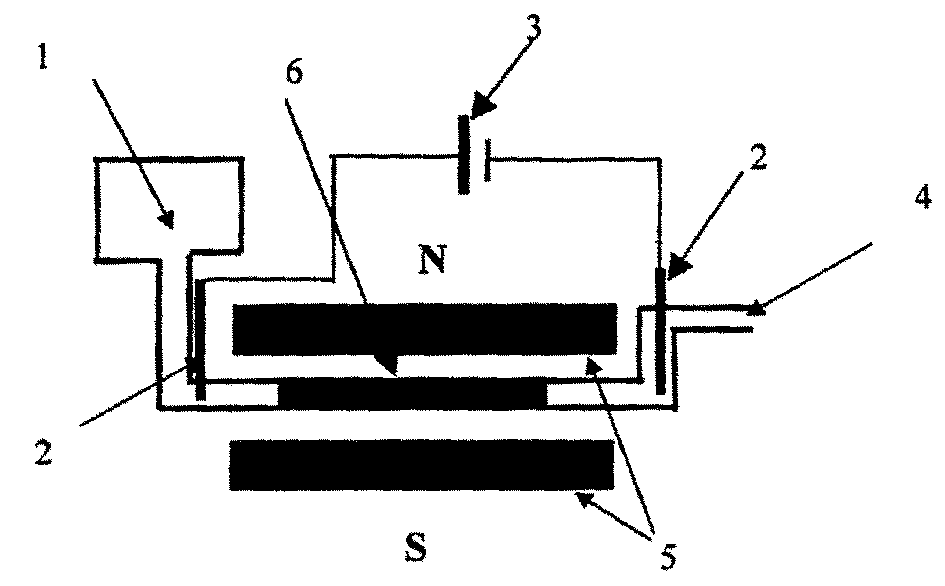

Method used

Image

Examples

Embodiment 1

[0023] Al-11.70wt% Si alloy is used, which contains 1.13wt% Fe. Melt in a resistance furnace, add Mn1.22wt% after melting, keep warm at 700°C for 30min, and perform electromagnetic filtration at 600°C. The Fe element in the Al-Si alloy is filtered by using the electromagnetic force application method of a steady magnetic field and a direct current. The cross-section of the single hole of the ceramic straight hole filter is 5mm×15mm, the length is 120mm, and the electromagnetic force is 1.5×10 4 N / m 3 . The contents of iron and manganese in the alloy after electromagnetic filtration are Fe0.67wt% and Mn0.50wt%, respectively.

Embodiment 2

[0025] On the basis of Example 1, carry out secondary filtration. A eutectic Al-11.70wt% Si alloy is used, which contains 0.67wt% Fe and 0.50wt% Mn. Melt in a resistance furnace, add Mn0.20wt% after melting, keep warm at 570°C for 50min, and perform electromagnetic filtration at 560°C. The Fe element in the Al-Si alloy is filtered by using the electromagnetic force application method of a steady magnetic field and a direct current. The cross-section of the single hole of the ceramic straight hole filter is 5mm×15mm, the length is 120mm, and the electromagnetic force is 1.5×10 4 N / m 3 . The contents of iron and manganese in the alloy after electromagnetic filtration are Fe0.41wt% and Mn0.28wt%, respectively.

Embodiment 3

[0027] A eutectic Al-11.70wt% Si alloy is used, which contains 1.15wt% Fe. Melt in a resistance furnace, add Mn1.55wt% after melting, keep warm at 720°C for 30min, and perform electromagnetic filtration at 580°C. A high-frequency magnetic field is used to filter Fe elements in Al-Si alloys. The cross-sectional diameter of the single hole of the ceramic straight hole filter is 5mm, the length is 150mm, the length of the coil is 200mm, the frequency of the magnetic field is 15kHz, and the power is 20kW. The contents of iron and manganese in the alloy after electromagnetic filtration are Fe0.78wt% and Mn0.45wt%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com