Laser linear scanning three-dimensional measurement double liquid knife virtual grid mapping calibrating method and equipment

A technology of three-dimensional measurement and virtual grid, applied in the direction of measuring device, optical device, image data processing, etc., can solve problems such as inability to fit, relationship cannot be accurately determined, and the actual situation is complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The structural principle, working principle and specific steps of calibration of the present invention will be described in detail below in conjunction with the accompanying drawings.

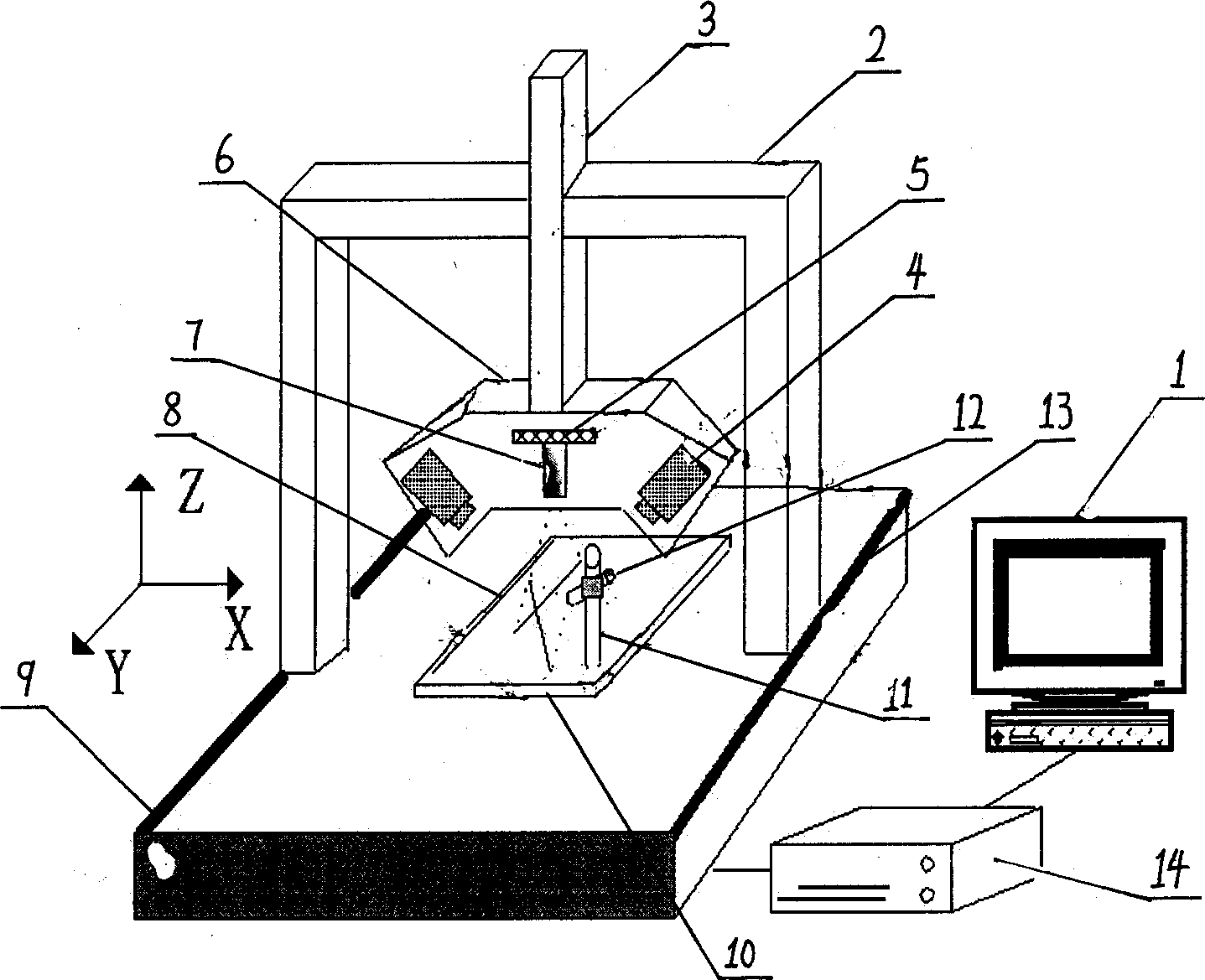

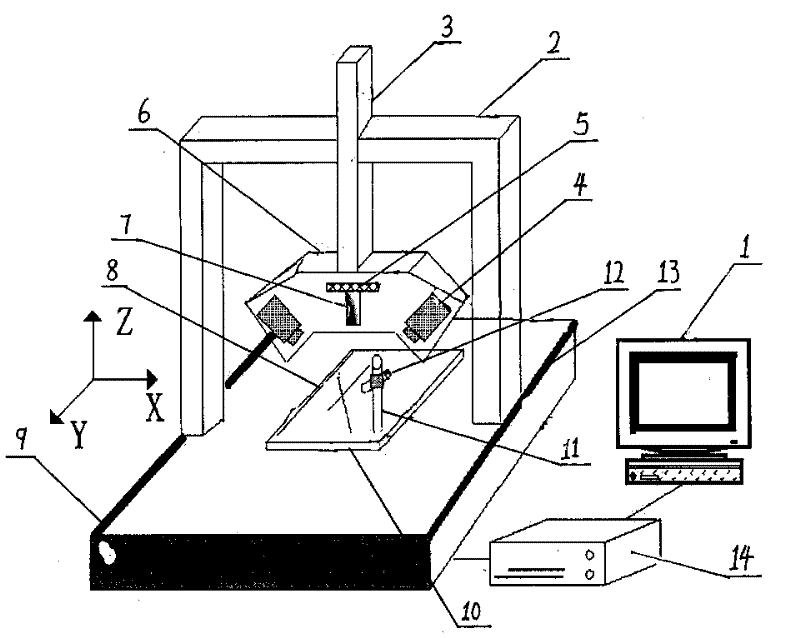

[0036] see figure 1, the present invention includes a central processing unit 1, a controller 14, a test base 9, and the test base 9 is provided with a gantry type vertically distributed X-axis translation guide rail 2, a Y-axis translation guide rail 13 and a Z-axis translation guide rail 3, X, Both the Y and Z axes are equipped with drive positioners, such as stepper motors or servo motors, grating rulers or photoelectric encoder disks, etc.; the lower end of the Z-axis translation guide rail 3 is connected to the photoelectric measuring head 6, and the middle part of the photoelectric measuring head 6 An adjustment device 5 is fixed, and a measurement light knife generator 7 is fixed on the lower end of the adjustment device 5, and the measurement light knife generator 7 can be adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com