Bi-rotation electric generator

A generator and outer rotor technology, applied in synchronous generators and other directions, can solve the problems of large capacity and small volume, and achieve the effect of large capacity, small volume and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

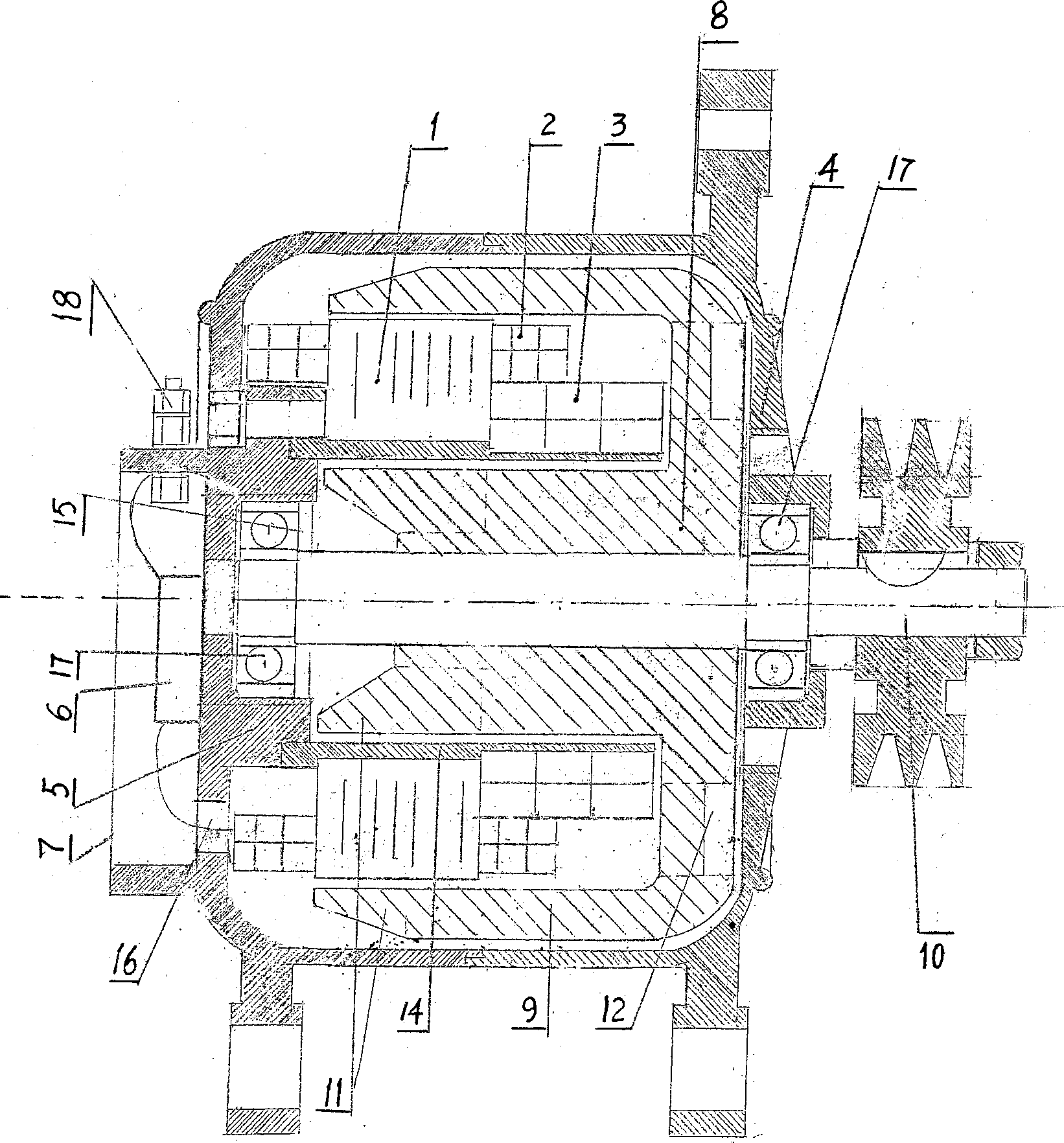

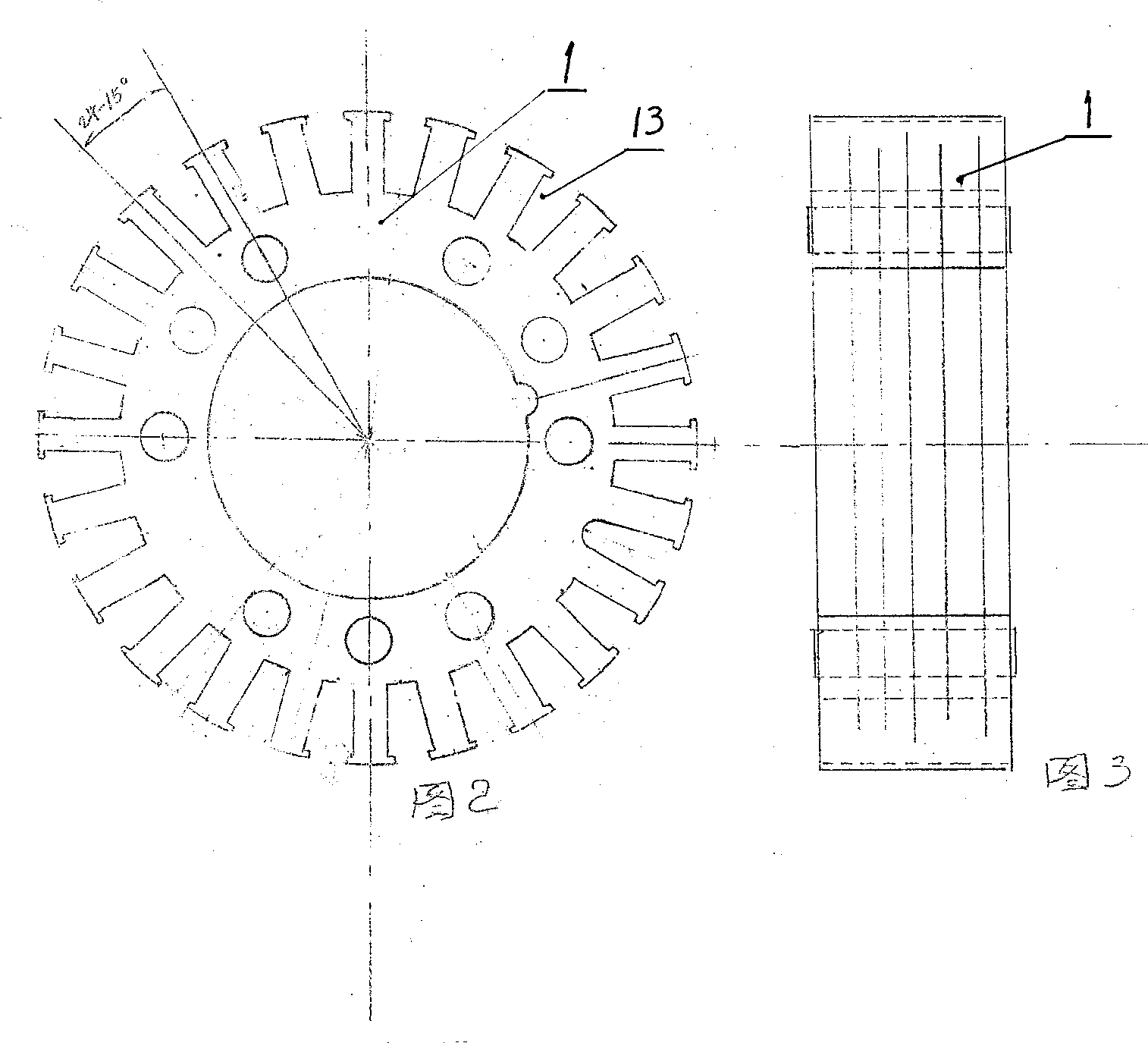

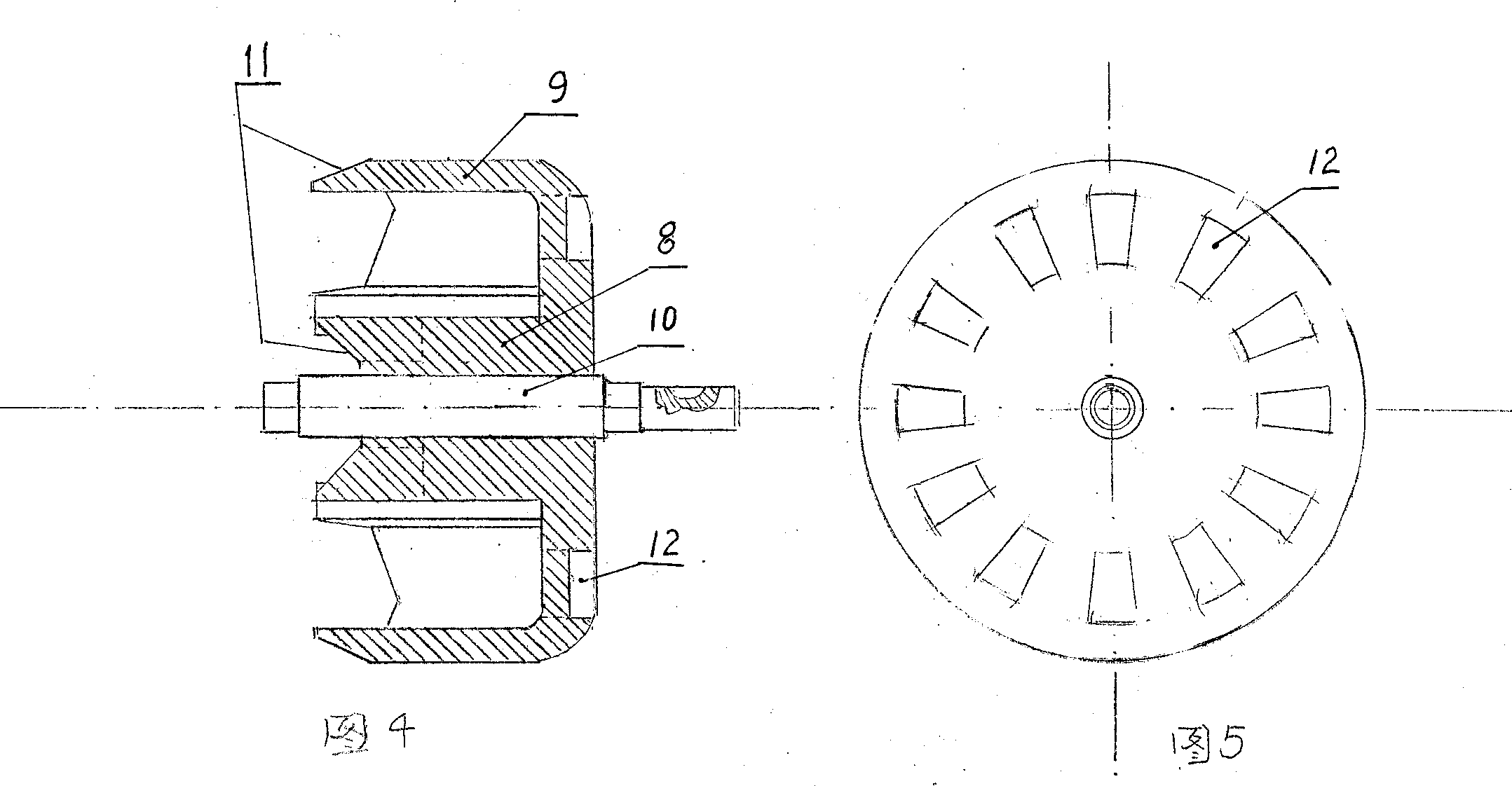

[0025] Such as Picture 1-1 As shown in 5, the generator is composed of inner and outer rotors, stator core 1, stator winding 2, field winding 3, front end cover 4, rear end cover 5, rectifier block 6 and shield 7 thereof. The inner rotor 8 is cylindrical, and the outer rotor 9 is barrel-shaped. The left end of the inner rotor 8 is connected with the inner bottom of the outer rotor 9 such as a barrel to form an inner and outer rotor. The inner and outer rotors are concentric, and the center of the inner and outer rotors There are circular through holes, which pass through the generator shaft 10; the left ends of the inner and outer rotors have 6 magnetically conductive teeth 11, and there are 12 other teeth on the outer rotor 9 barrel-shaped bottom except for the 10 holes in the center that pass through the generator shaft. Trapezoidal ventilation holes 12. The stator core 1 is made of folded and riveted silicon steel sheets. The shape of the stator core 1 is cylindrical. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com