Transfer mechanism, image-forming device using same and method for mfg. transfer device

An imaging device and transfer printing technology, applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, and the electric recording technique, etc., can solve the problems of the reduction of the surface reflectivity of the transfer roller, large rotation load, Problems such as toner contamination of the transfer roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

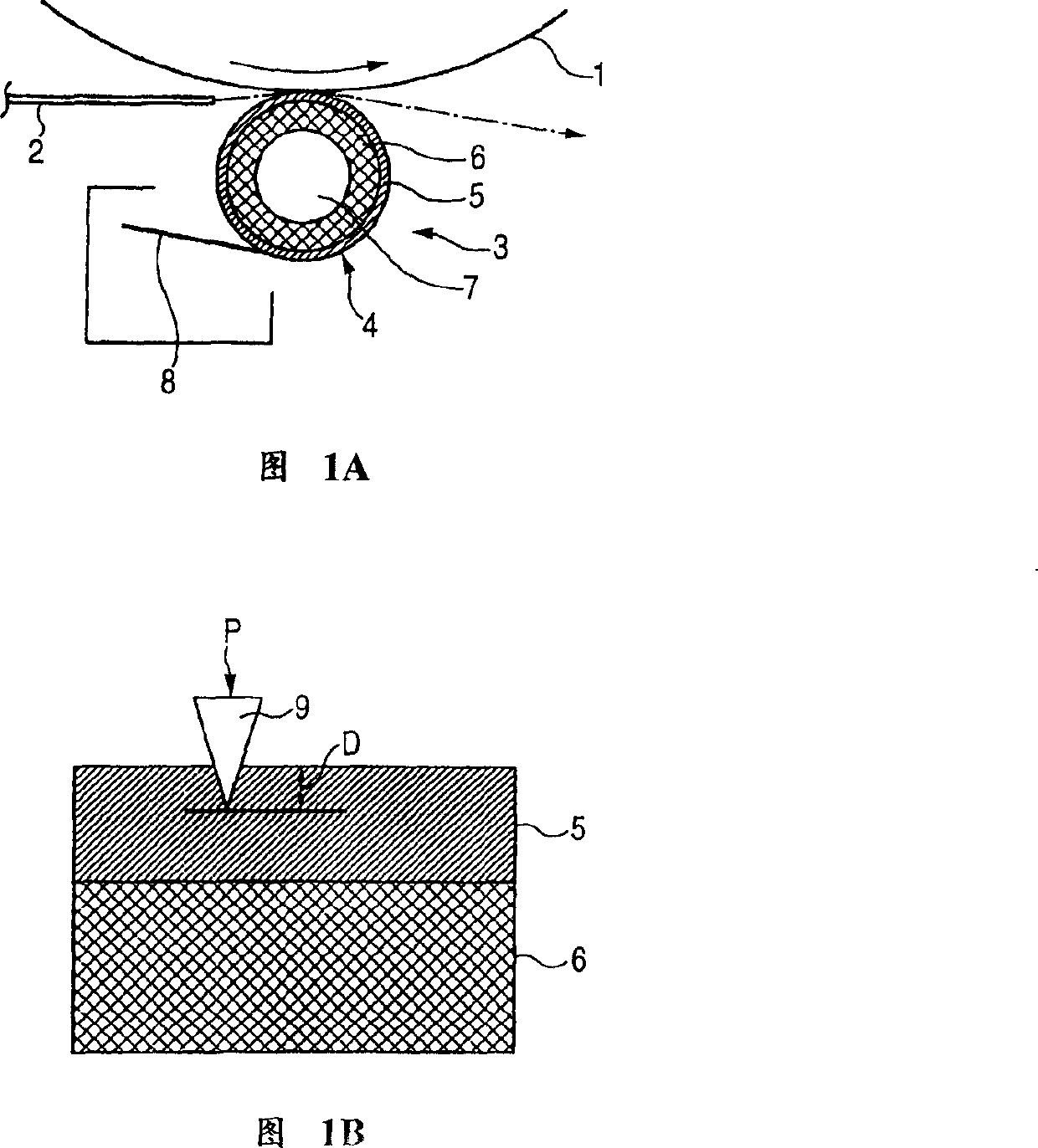

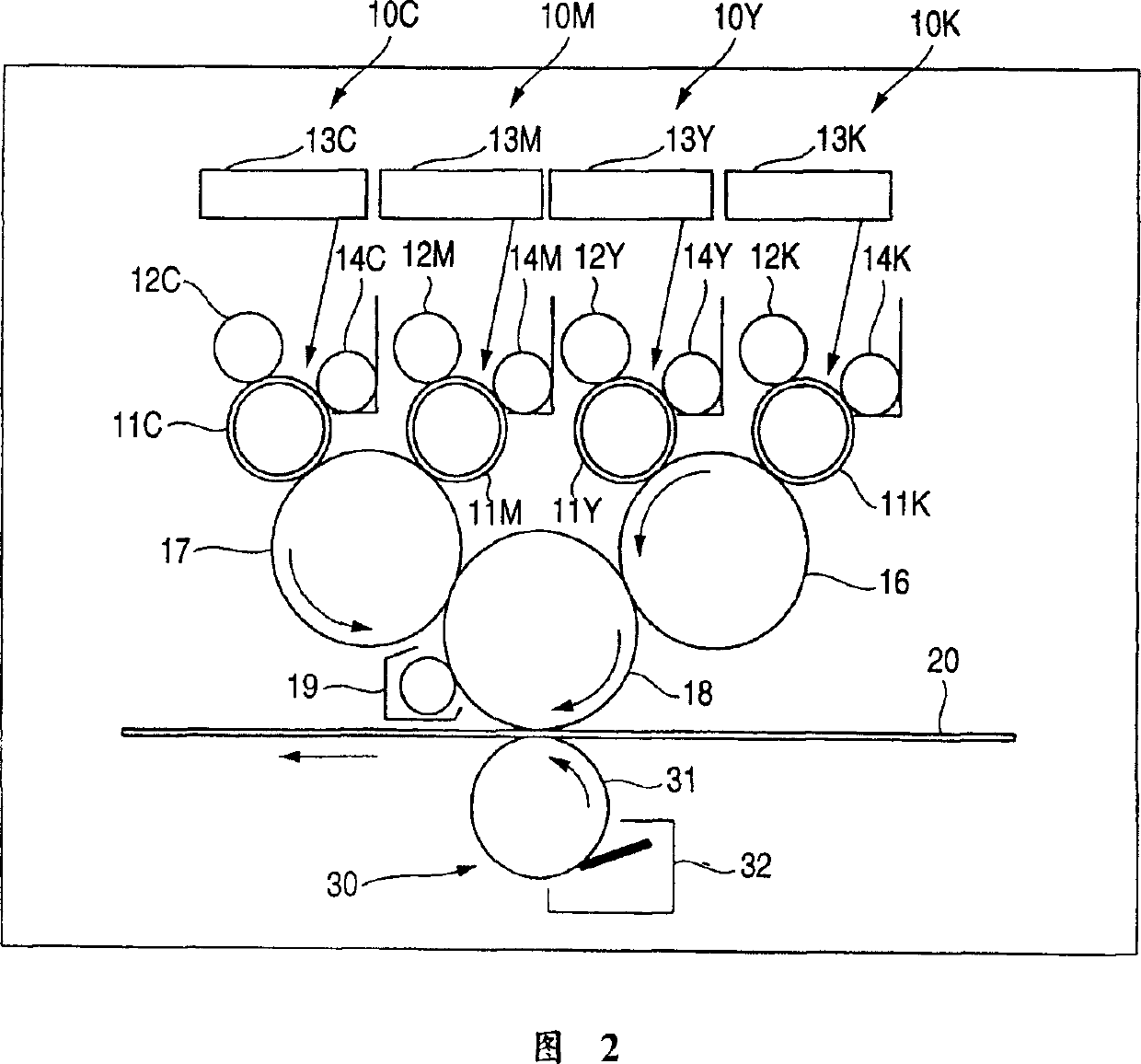

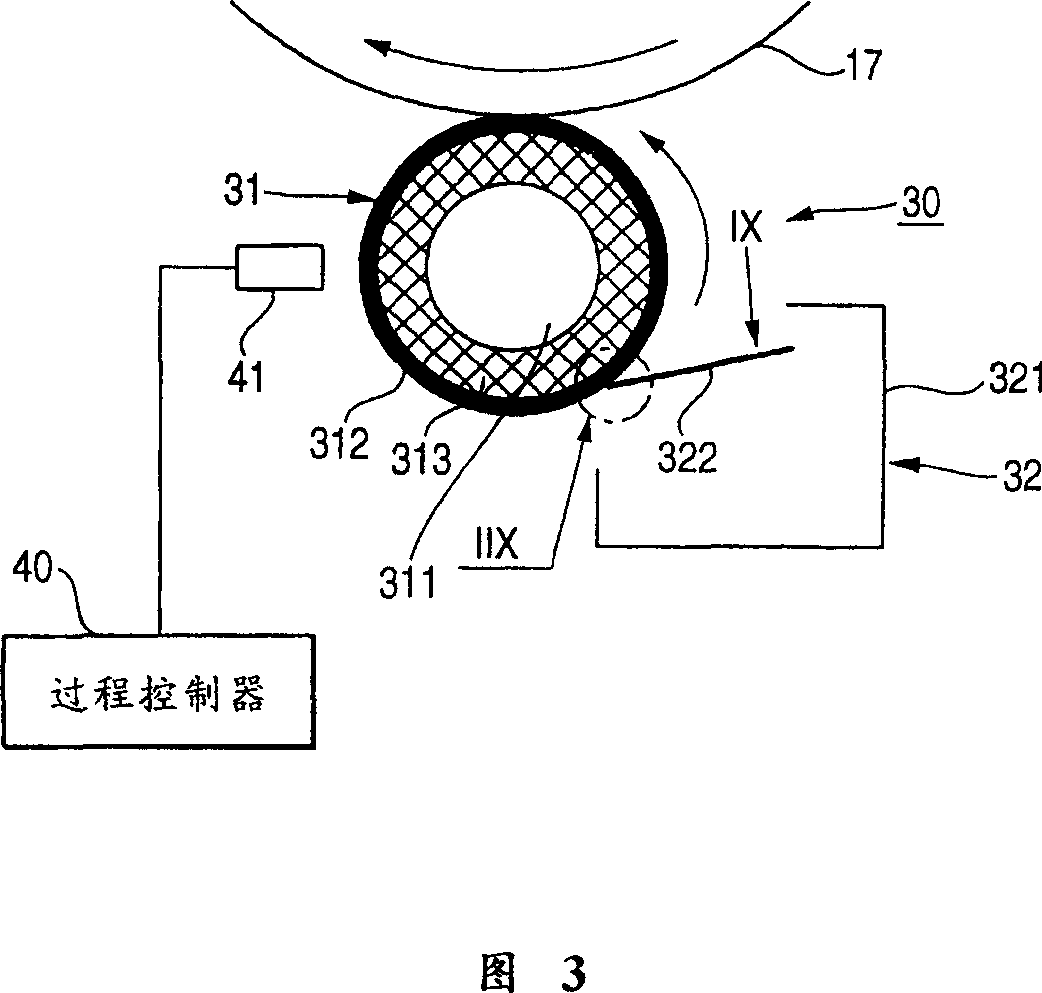

[0112] FIG. 2 is a schematic diagram showing the overall structure of an imaging device according to a first embodiment of the present invention.

[0113] In FIG. 2 , the image forming apparatus is, for example, an intermediate transfer type tandem image forming apparatus, adopts an electrophotographic method, and includes four image forming units 10 (specifically, 10K, 10Y, 10M, and 10C), and among the four image forming units, respectively Black (K), yellow (Y), magenta (M) and cyan (C) toner images are formed.

[0114] Each image forming unit 10 (10K-10C) includes a photosensitive drum 11 (11K-11C) on which an electrostatic latent image is formed and supported. An electrophotographic mechanism such as a charging mechanism 12 (12K-12C) (charging roller in this example) for charging the photosensitive drum 11 is provided around the photosensitive drum 11 for forming colors corresponding to the respective color components on the charged photosensitive drum 11. The exposure me...

no. 2 example

[0174] Fig. 10 is a schematic diagram of an essential part of a second embodiment of an image forming apparatus to which the present invention is applied.

[0175] In FIG. 10, the basic structure of the image forming apparatus is almost the same as that of the first embodiment, but the structure of the transfer mechanism 30 is different from that of the first embodiment. In the case where the constituent elements are the same as those of the first embodiment, the same reference numerals are used and further description thereof is omitted.

[0176] In this embodiment, unlike the first embodiment, the transfer roller 31 of the transfer mechanism 30 includes an adjustment resistance layer 315 made of, for example, polyurethane formed on a roller (core) 311 made of a metal such as aluminum. and a protective resin layer 314 made of epoxy resin with high surface abrasion resistance, which is formed on the adjustment resistance layer 315 .

[0177] In this embodiment, the protective...

no. 3 example

[0189] FIG. 11A is a schematic diagram showing an essential part of a third embodiment of an imaging apparatus to which the present invention is applied.

[0190] In FIG. 11A , unlike the first and second embodiments, a transfer mechanism 30 includes a transfer belt 33 instead of a transfer roller 31 .

[0191] The transfer belt 33 shown in FIG. 11A includes a belt member 333 having a protective resin layer 333a made of polyimide formed at least on its surface and an adjustment resistance layer 333b as a base layer, and the belt member is wound around a supporting roller 331. and 332. A bias roller 334 that applies a transfer bias is disposed opposite to the intermediate transfer drum 18 with the belt 333 interposed therebetween.

[0192] A belt cleaner 34 (having a metal blade 342 ) is disposed opposite to the backup roller 332 of the transfer belt 33 . The metal scraper 342 is provided in contact with the surface of the transfer belt 33 to clean the surface of the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com