Individual element photoelectric measuring device for pane object

A technology for measuring objects and objects, which is applied in measuring devices, color measuring devices, optical devices, etc., and can solve problems such as large distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

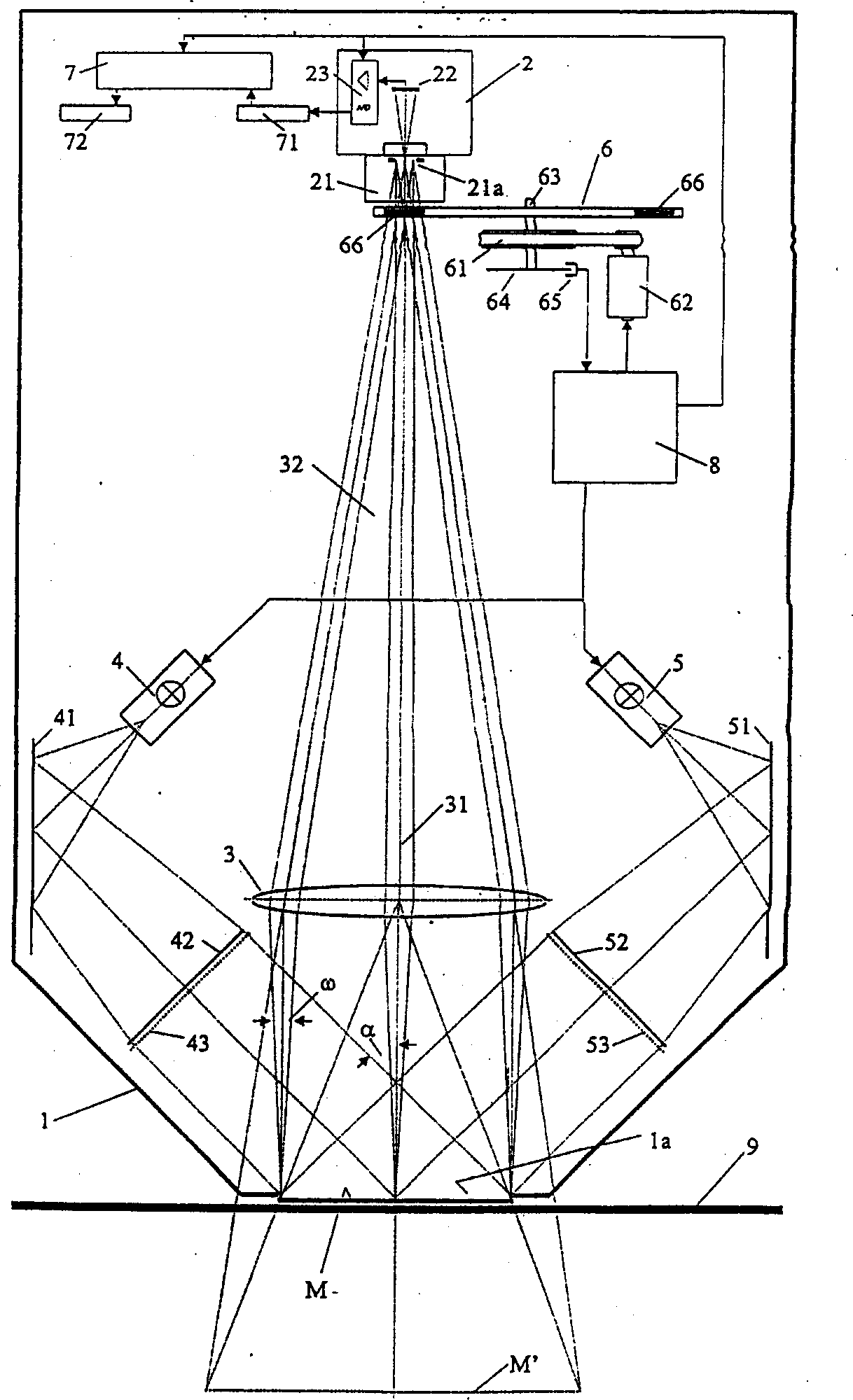

[0026] Such as figure 1 As shown, the measuring device according to the first preferred embodiment of the present invention comprises a light-tight housing 1 with a measuring window 1a, a camera 2, a remote lens 3 preferably configured as a Fresnel lens, two A flashlight source 4 and 5, two redirecting mirrors 41 and 51, two illumination lenses 42 and 52 preferably configured as Fresnel lenses, two color mixing filters 43 and 53 at the illumination lenses, filter Light wheel 6 , belt drives 61 , 62 , angle encoder 64 connected to shaft 63 of filter wheel 6 with associated sensor 65 , data processor 7 and central processing controller 8 . Preferably, the data processor 7 and the central processing controller 8 are implemented by a digital computer, but they can also be arranged outside the casing 1 of course.

[0027] The video camera 2 has the usual structure comprising, as relevant part of the invention, a standard imaging lens 21, an image sensor 22 in the form of a two-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com