Separation of azeotropic mixture

A technology of mixtures and azeotropes, applied in the field of separation of liquid mixtures, can solve problems such as limiting distillation temperature and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

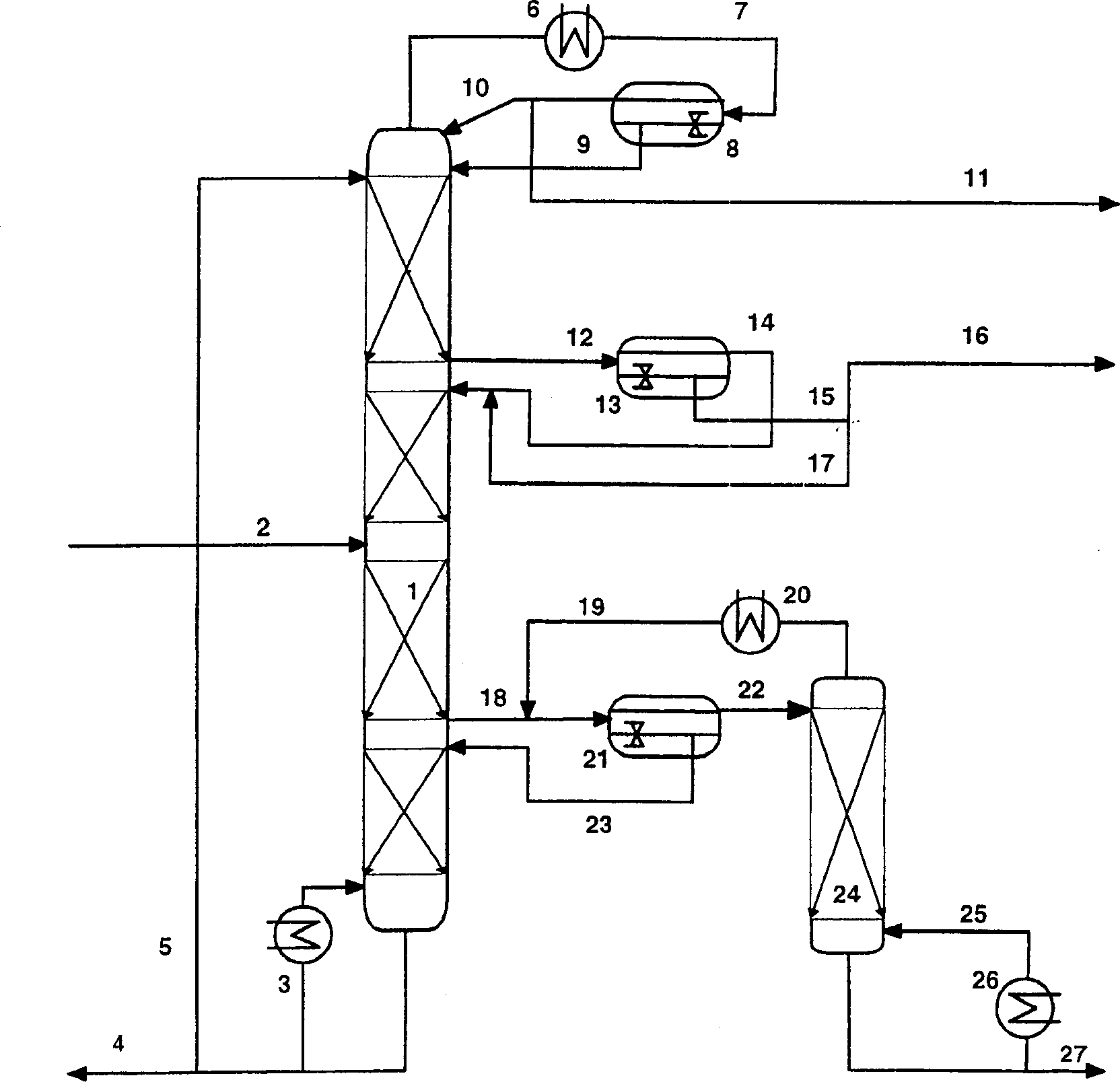

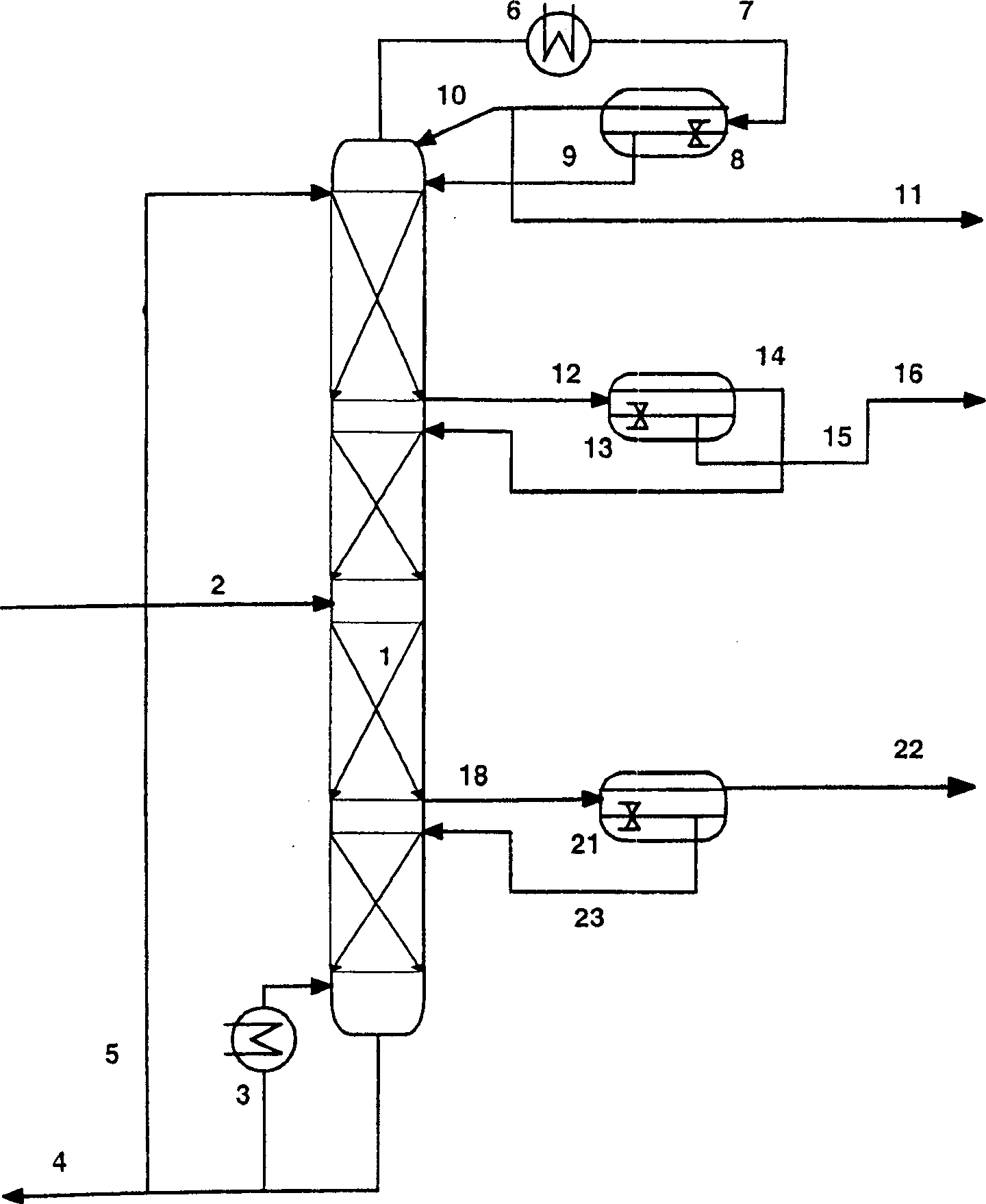

[0047] use figure 2 device shown.

[0048] A liquid mixture consisting of 44% by weight of 1-butanol, 40.6% by weight of perchlorethylene, 14.2% by weight of water and 1.2% by weight of butyl chloride is fed into column (1) via line (2). The composition of each stream is shown in Table 1.

[0049] The glass column ( 1 ) has a diameter of 43 mm, has 20 theoretical plates, and is filled with a screen packing of type CY from Sulzer Chemtech AG, Winterthur. The reflux ratio of the organic phase was 30. The column operates at a top pressure of 1 bar. The temperature at the bottom of the column was 104°C, and the temperature at the top of the column was 69°C. The feed point (2) is approximately in the middle of the column, above the second packing element of the 10th theoretical plate. The recycle stream (5) is returned to the column above the top of the fourth packing element. Stream (18) is withdrawn from the bottom of the second packing element in the middle of the lower s...

Embodiment 2

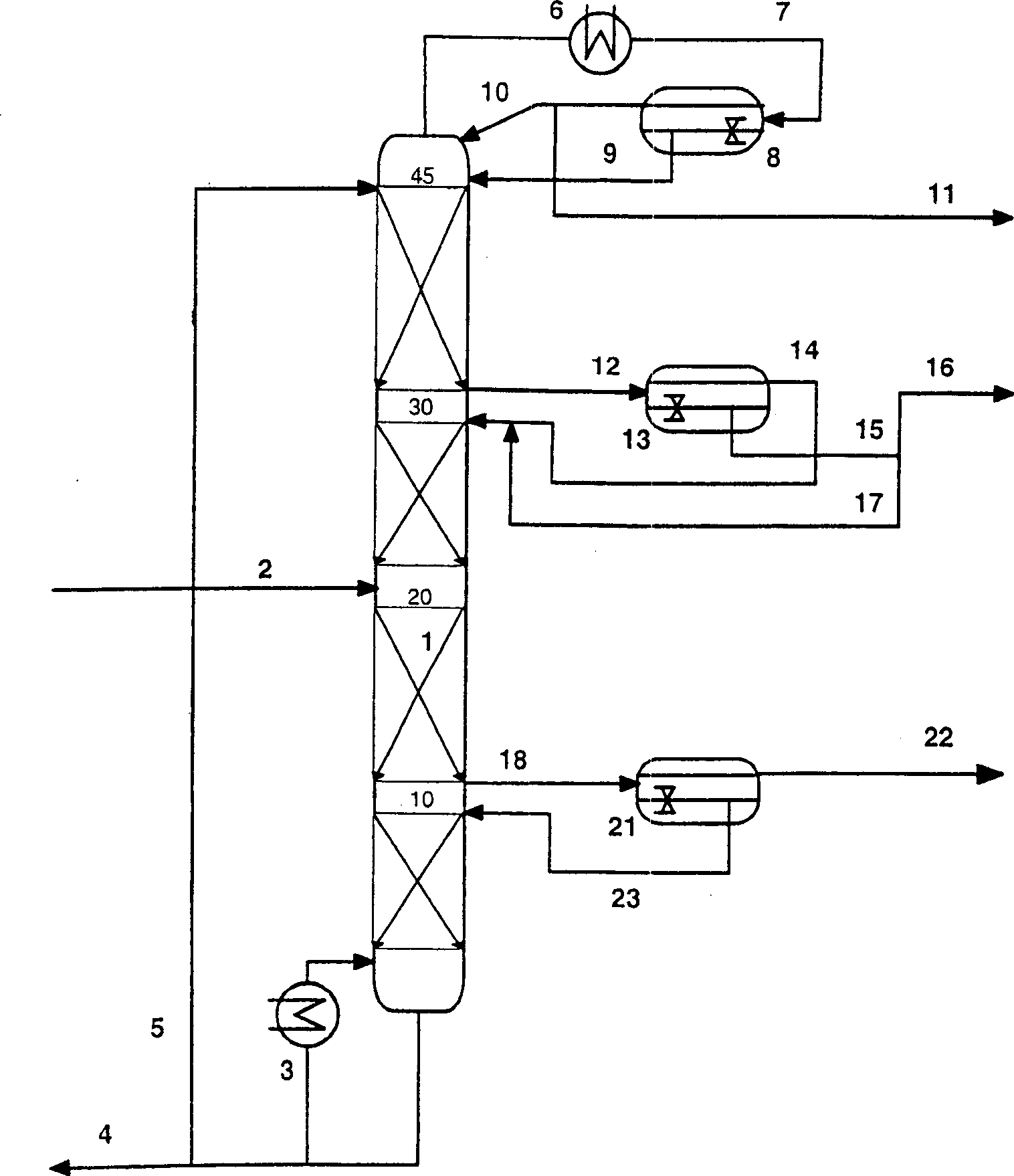

[0052] use image 3 device shown.

[0053] A liquid mixture consisting of 44% by weight of 1-butanol, 40.6% by weight of perchlorethylene, 14.2% by weight of water and 1.2% by weight of butyl chloride is fed into column (1) via line (2). The composition of each stream is shown in Table 2.

[0054] The glass column (1) has a diameter of 30 mm and is equipped with 45 bubble-cap trays. The reflux ratio of the organic phase was 30. The column operates at a top pressure of 1 bar. The temperature at the bottom of the column was 101.5°C, and the temperature at the top of the column was 68°C. The feed point (2) is approximately in the middle of the column, at the 20th theoretical plate. The recycle stream (5) is returned to the column on the uppermost tray.

[0055] logistics

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com