Detergent compositions containing modified alkylaryl sulfonate surfactants

A technology of surfactant, alkyl benzene sulfonate, applied in the direction of surface active detergent composition, detergent composition, non-ionic surface active compound, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

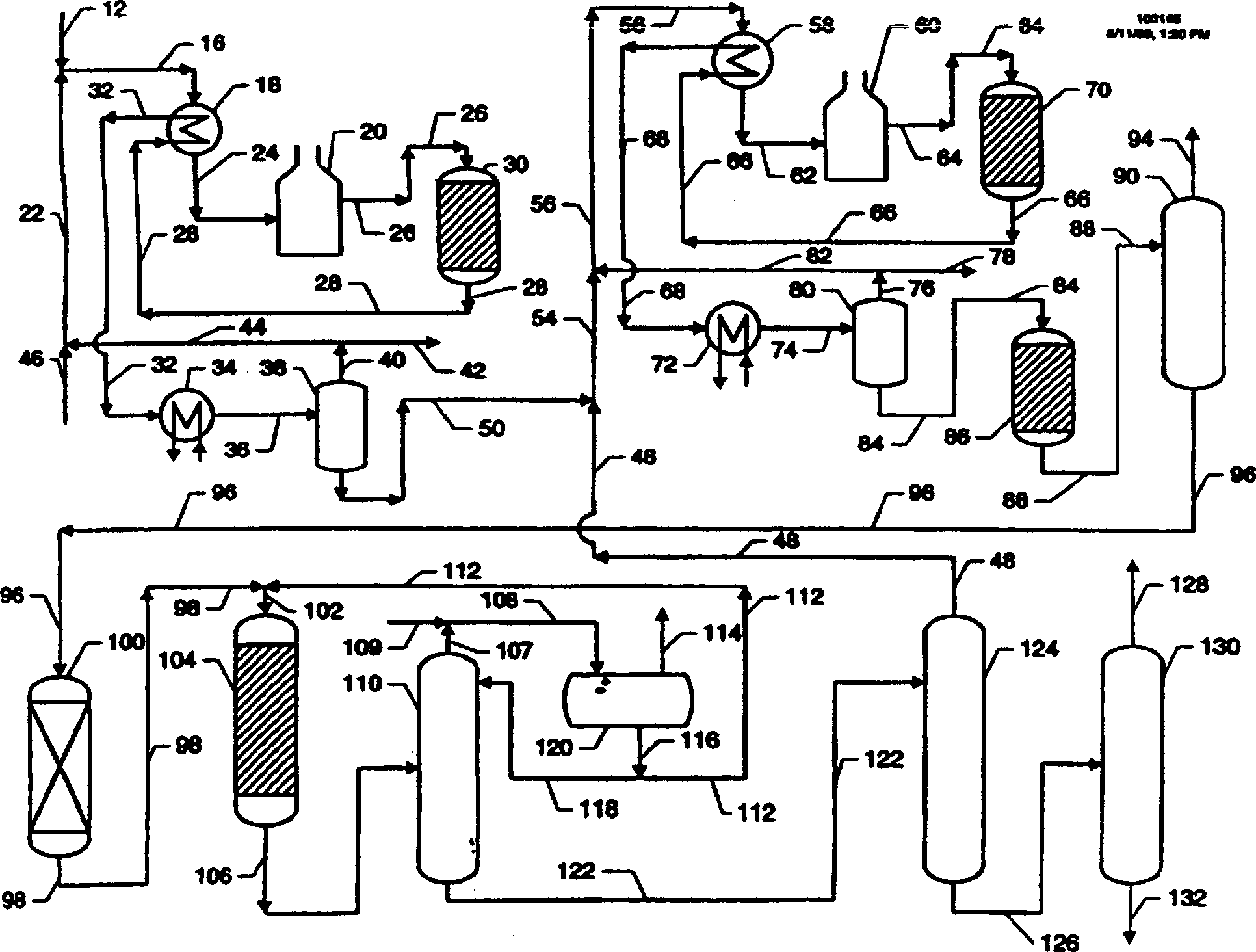

Image

Examples

Embodiment 1

[0144] The catalyst used in Example 1 was prepared by coextrusion of 0.39 wt% platinum on a support containing extrudates of 60 wt% SAPO-11 and 40 wt% alumina. During the isomerization, the conversion was 73.4 mol%, the monomethyl selectivity was 55.5 mol%, the light yield was 7.9 mol%, and the heavy yield was 0.01 mol%.

Embodiment 2

[0146] The catalyst used in Example 2 was prepared by impregnating 0.26 wt% platinum with 50 wt% MgAPSO-31 and 50 wt% alumina. During the isomerization, the conversion was 73.3 mol%, the monomethyl selectivity was 69.6 mol%, the light yield was 13.5 mol%, and the heavy yield was less than 0.01 mol%.

[0147]Examples 1 and 2 show that good conversion and high selectivity to monomethyl paraffins can be obtained with isomerization catalysts containing SAPO-11 and MgAPSO-31.

Embodiment 3

[0150] Example 3 illustrates a preferred dehydrogenation catalyst for use in the present invention and a method of preparing the catalyst. Alumina spheres were prepared by the known oil drop method described in US2620314, incorporated herein by reference. The method involves forming an aluminum hydrosol by dissolving aluminum metal in hydrochloric acid; adding hexamethylenetetramine to the sol, which gels when dispersed as droplets in an oil bath maintained at about 93°C (199°F) for the sphere. The droplets are kept in the oil bath until they coagulate and form hydrogel spheres. The spheres were then successively removed from the hot oil bath, followed by pressure aging at 135°C (275°F) and washing with dilute ammonium hydroxide solution, drying at 110°C (230°F), and then drying at about 650°C (1202°F) sintering for about 2 hours to obtain gamma-alumina balls. The resulting sintered alumina was crushed into a fine powder with a particle size of less than 200 microns (0.0078...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com