Mechanism for milling impeller inducer of centrifugal compressor with ordinary milling machine

The technology of centrifugal compressor and air guide impeller is applied in the field of processing devices, which can solve the problems of unstable quality, low impeller strength and high processing cost, and achieve the effects of simple structure, convenient operation and use, and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

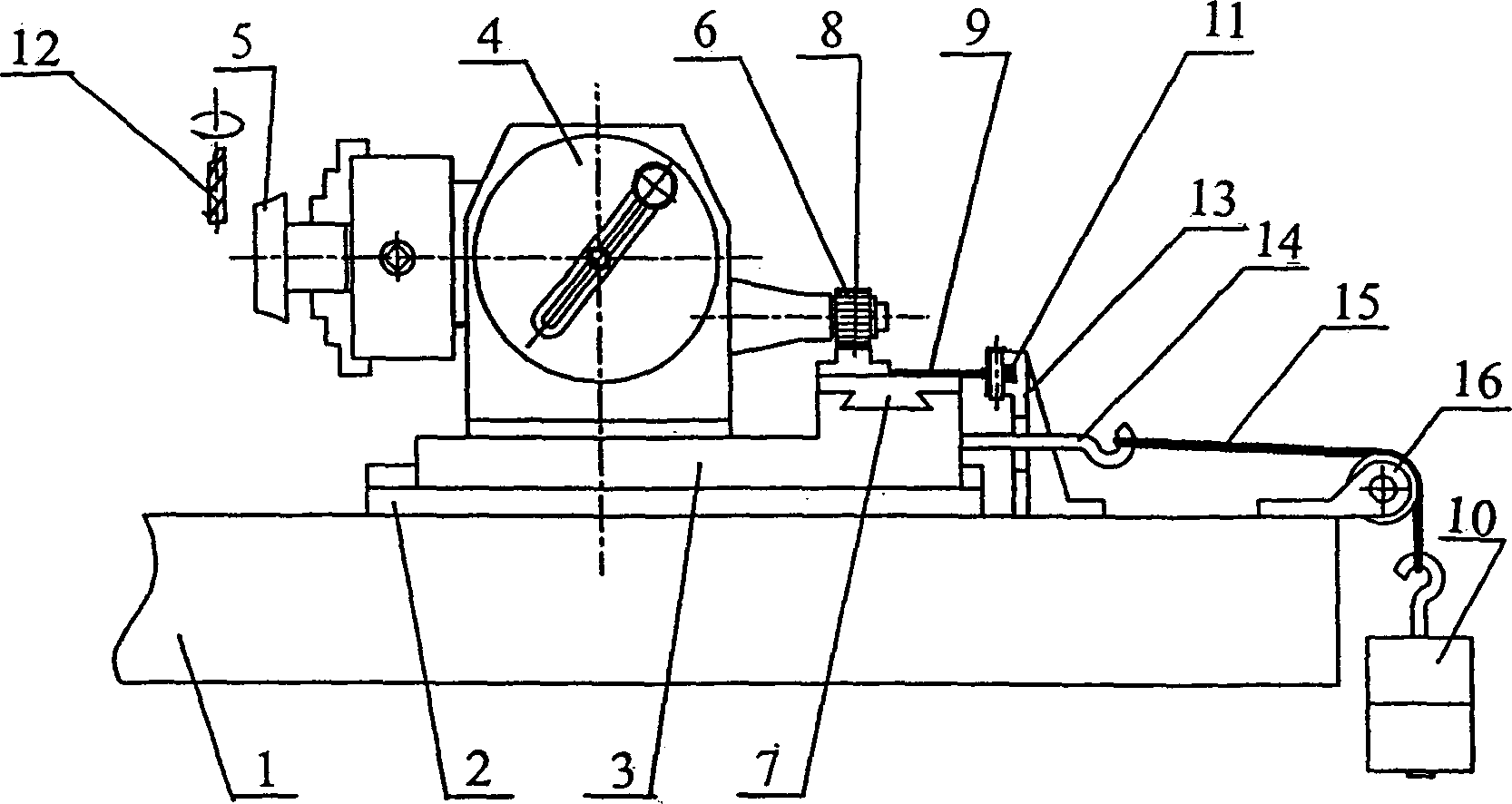

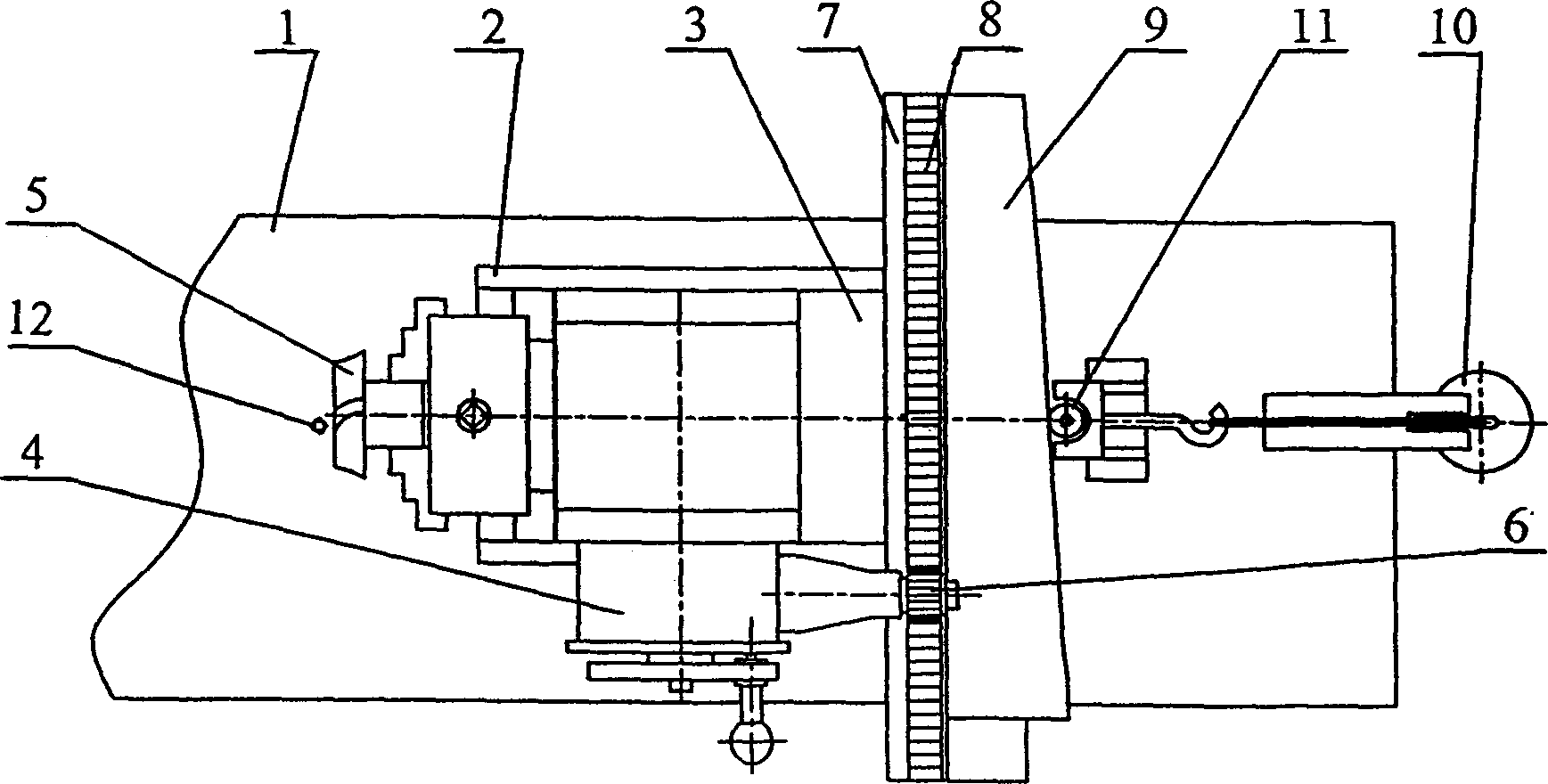

[0012] Such as figure 1 , figure 2 As shown, it includes a longitudinal sliding seat 2 installed on the vertical milling machine table 1, and a milling machine dividing head 4 is installed on the sliding plate 3 that can move longitudinally on the longitudinal sliding seat 2. The sliding plate 3 is equipped with a horizontal sliding plate 7 and a hook. The screw 14, the transmission gear 6 on the indexing head 4 meshes with the rack 8 fixed on the horizontal slide 7, the template 9 is fixed on the horizontal slide 7, the vertical milling machine table 1 is equipped with a roller frame 13 and a pulley frame 16, Nylon rope 15 on the hook screw 14 hangs heavy hammer 10 through the pulley on the pulley frame 16, and the roller 11 on the roller frame 13 is pushed against template 9 sides all the time.

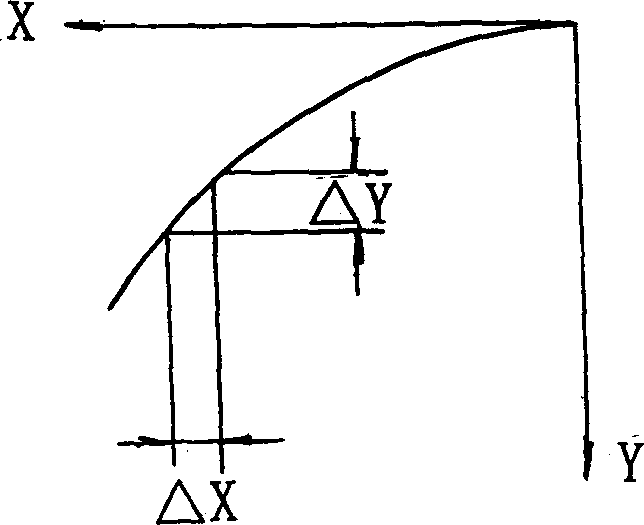

[0013] Such as image 3 , Figure 4 As shown, according to the profile line coordinates on the average diameter of the vane inlet of the vane, the template curve and the vane cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com