Ultralow-temp adhesive lining cloth and its making method

A technology of adhesive interlining and manufacturing method, which is applied in the direction of film/sheet adhesive, adhesive, textile and paper making, etc., can solve the problems of wrinkle deformation, poor heat resistance, reduced fabric fluff, etc., to improve the use value, Easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

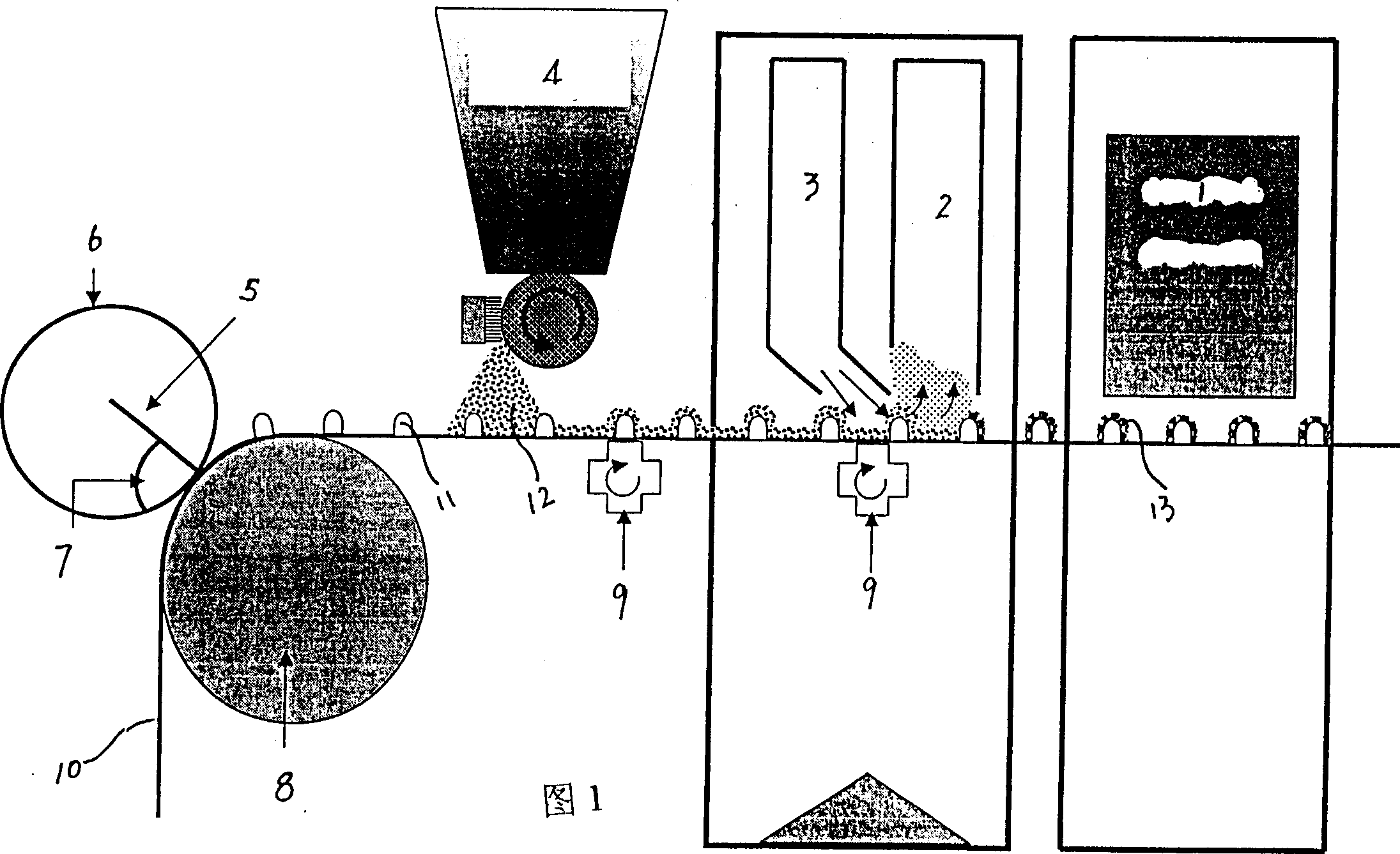

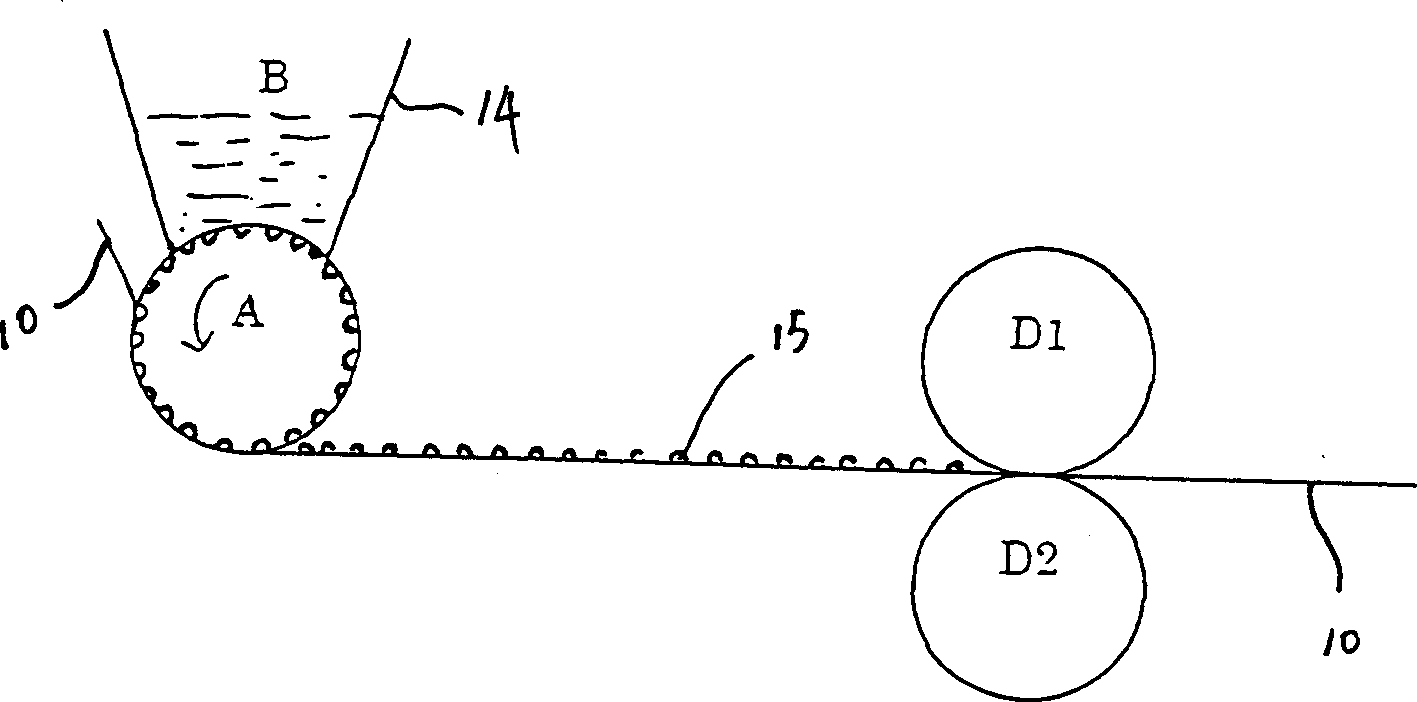

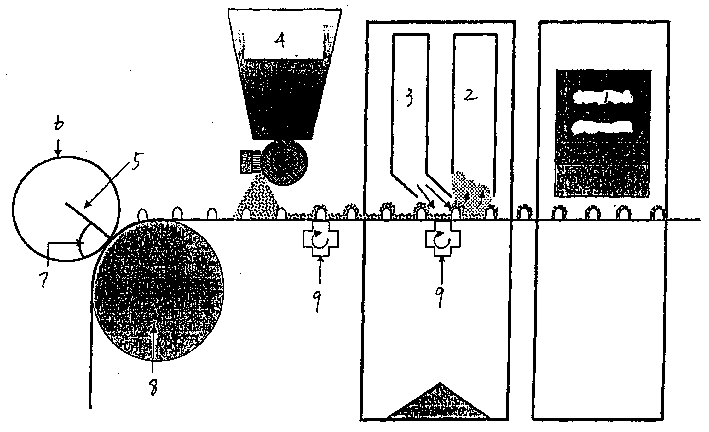

Method used

Image

Examples

Embodiment 1

[0056] Raw material: T5211 polyester cotton

[0057] 1. Scouring: Add scouring liquid made of water and additives into the liquid tank of the refining machine. The additives are 10 g / L of sodium hydroxide, 10 g / L of hydrogen peroxide, and 3 g / L of metal ion chelating agent. , Scouring detergent 1 g / L, desizing agent 3 g / L, hydrogen peroxide stabilizer 3 g / L, and the rest is water. Let the fabric pass through the liquid tank, paddle the scouring liquid, and then enter the scouring container—the reaction tower for scouring. The temperature of the first tower is 80°C, the temperature of the second tower is 60°C, and the time is 40 minutes. After the reaction, it is washed by the water tank. Take out after drying;

[0058] 2. Dyeing: First, use disperse dyes in the cylinder pad dyeing machine to dye polyester, and add a dye solution made of water and additives into the liquid tank of the pad dyeing machine. The additives are disperse dyes 50 g / L, metal ion chelating agent 1 g / L,...

Embodiment 2

[0066] Raw material: T5211 polyester cotton

[0067] 1. Scouring: Add scouring liquid made of water and additives into the liquid tank of the refining machine. The ingredients of the additives are 20 g / L of sodium hydroxide, 30 g / L of hydrogen peroxide, and 8 g / L of metal ion chelating agent , Scouring detergent 4 g / L, desizing agent 8 g / L, hydrogen peroxide stabilizer 8 g / L, and the rest is water. Let the fabric pass through the liquid tank, paddle the scouring liquid, and then enter the scouring container—the reaction tower for scouring. The temperature of the first tower is 120°C, the temperature of the second tower is 90°C, and the time is 60 minutes. After the reaction, it is washed by the water tank. Take out after drying;

[0068] 2. Dyeing: First, use disperse dyes in the cylinder pad dyeing machine to dye polyester, and add a dye solution made of water and additives into the liquid tank of the pad dyeing machine. The additives are disperse dyes 60 g / L, metal ion che...

Embodiment 3

[0076] Raw material: T5211 polyester cotton

[0077] 1. Scouring: add scouring liquid made of water and additives into the liquid tank of the refining machine. The ingredients of the additives are 15 g / L of sodium hydroxide, 20 g / L of hydrogen peroxide, and 5 g / L of metal ion chelating agent , Scouring detergent 2 g / L, desizing agent 5 g / L, hydrogen peroxide stabilizer 5 g / L, and the rest is water. Let the fabric pass through the liquid tank, paddle the scouring liquid, and then enter the scouring container—the reaction tower for reaction scouring. The temperature of the first tower is 100°C, the temperature of the second tower is 80°C, and the time is 50 minutes. After the reaction, it is washed by the water tank , take out after drying;

[0078] 2. Dyeing: First, use disperse dyes in the cylinder pad dyeing machine to dye polyester, and add a dye solution made of water and additives into the liquid tank of the pad dyeing machine. The additives are disperse dyes 55 g / L, met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com