Robot for high-voltage hot-line work

A working robot and high-voltage live technology, which is applied to cable installation devices, cable installation, manipulators, etc., can solve the problems of limited application range, inability to complete live repair and maintenance of insulators and lightning arresters, and achieve wide application range and positioning accuracy High, high dielectric strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

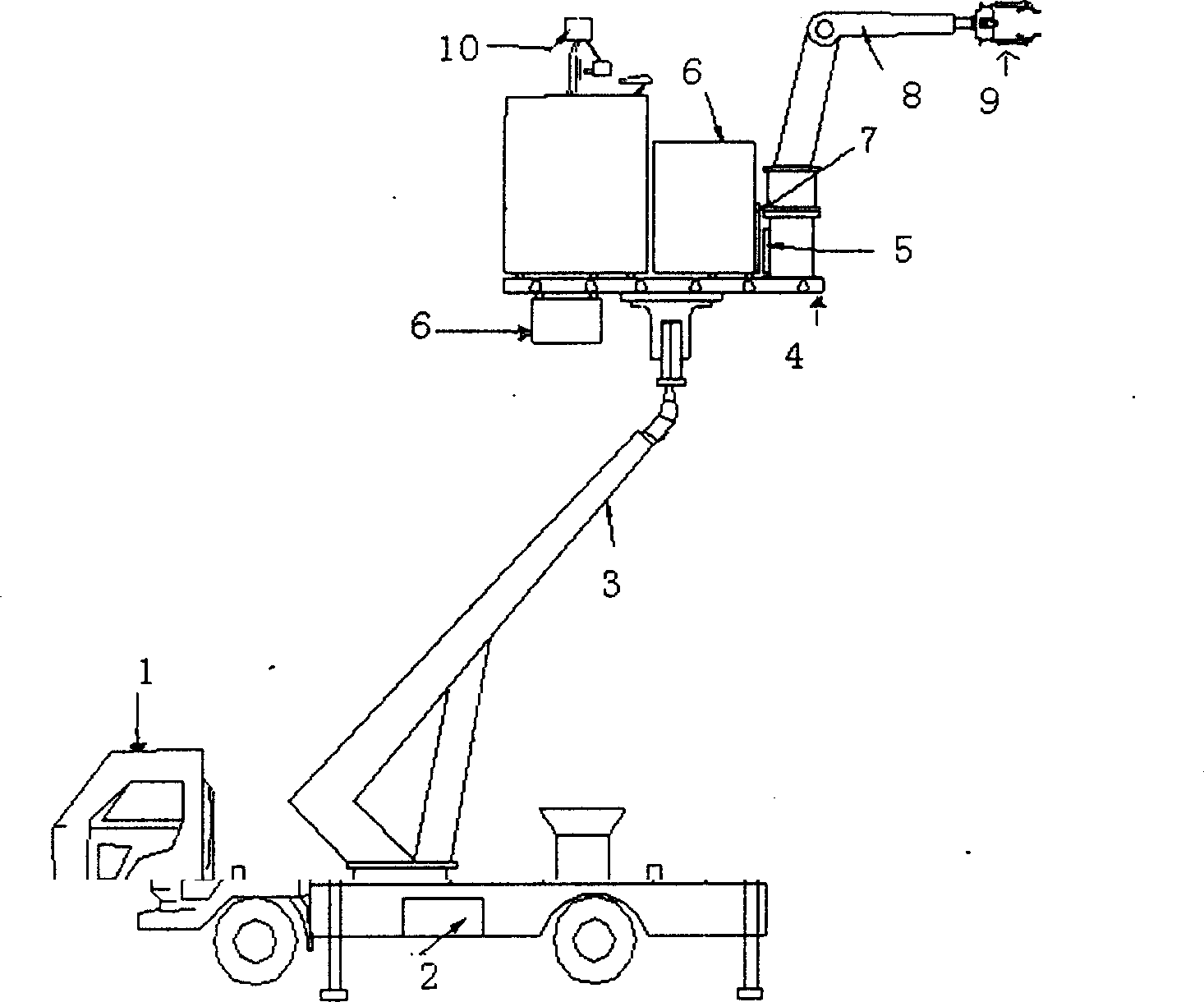

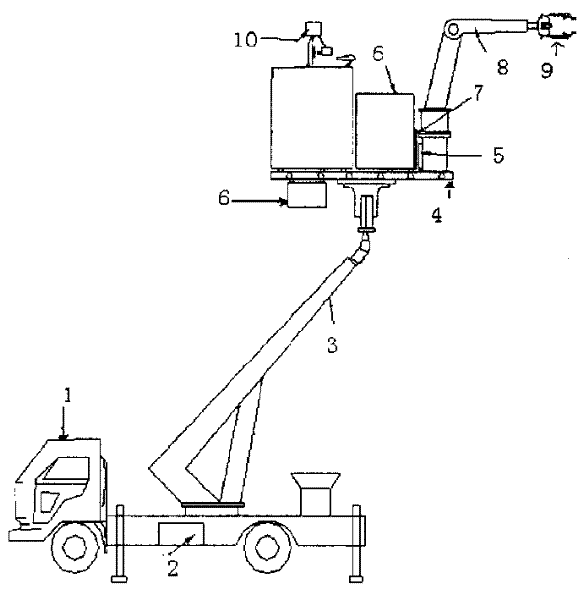

[0014] exist figure 1 In the shown embodiment, the lifting system (3), the generator and the hydraulic oil pump (2) are installed on the chassis of the car (1), and can be dragged by the car, and the insulating support platform (4) is connected with the end of the lifting system (3) . The lifting mechanism (3) is driven by hydraulic pressure, the maximum oil pressure can reach 20Mpa, and it has four degrees of freedom of rotation, expansion and contraction, end swing and platform leveling. Two articulated 6-DOF operating manipulators (8) are fixed on the insulating platform (4), and the end wrist of the operating manipulator (8) is equipped with a manipulator (9) with high insulation strength, and the operating manipulator (8) adopts MINS servo The motor drives the RV reducer, the manipulator (9) is hydraulically driven, and the hydraulic pump (2) supplies oil to the manipulator (9). The secondary winding leads of the isolation transformer (7) installed on the insulating supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com