Spiral electrode group winding method and device and battery using them

A technology of winding device and electrode group, applied in the direction of assembling battery machine, non-aqueous electrolyte storage battery, aqueous electrolyte battery, etc. Stable and excellent production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

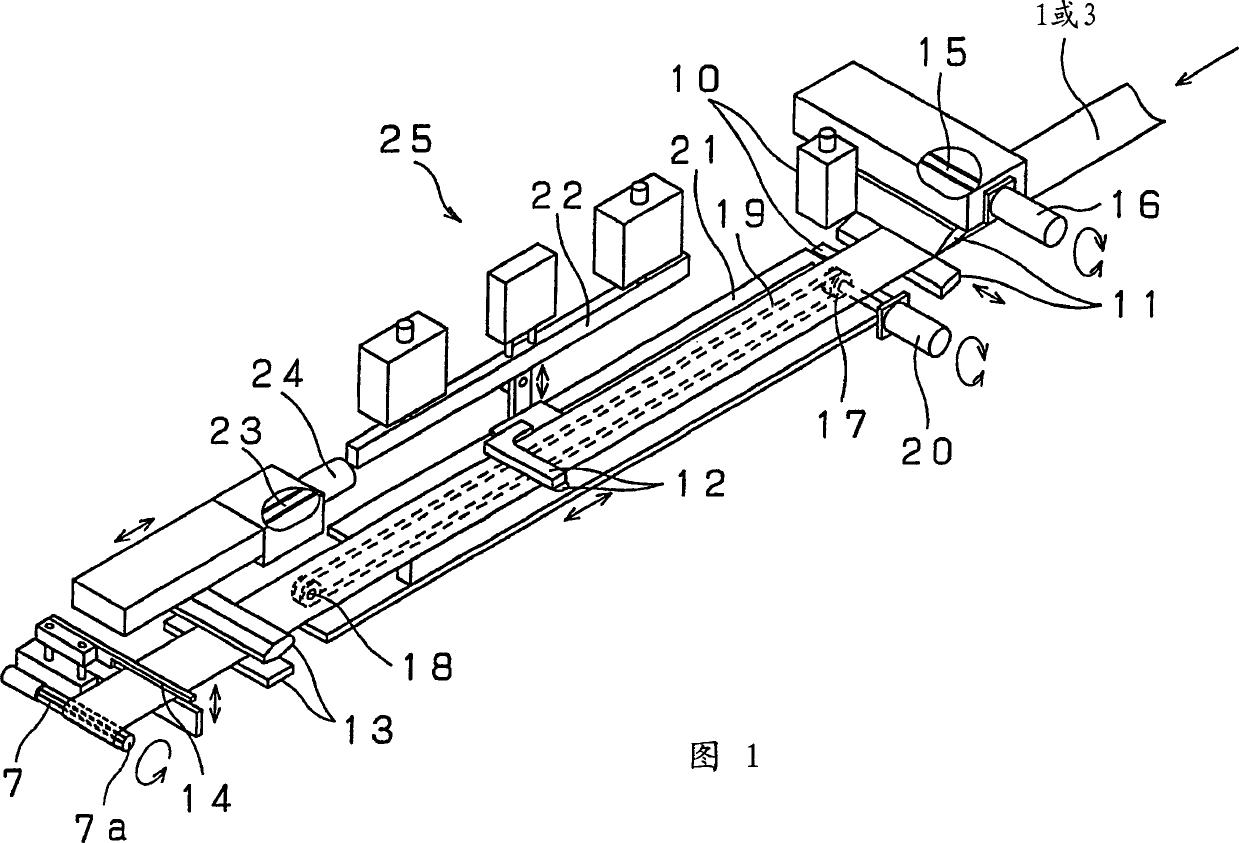

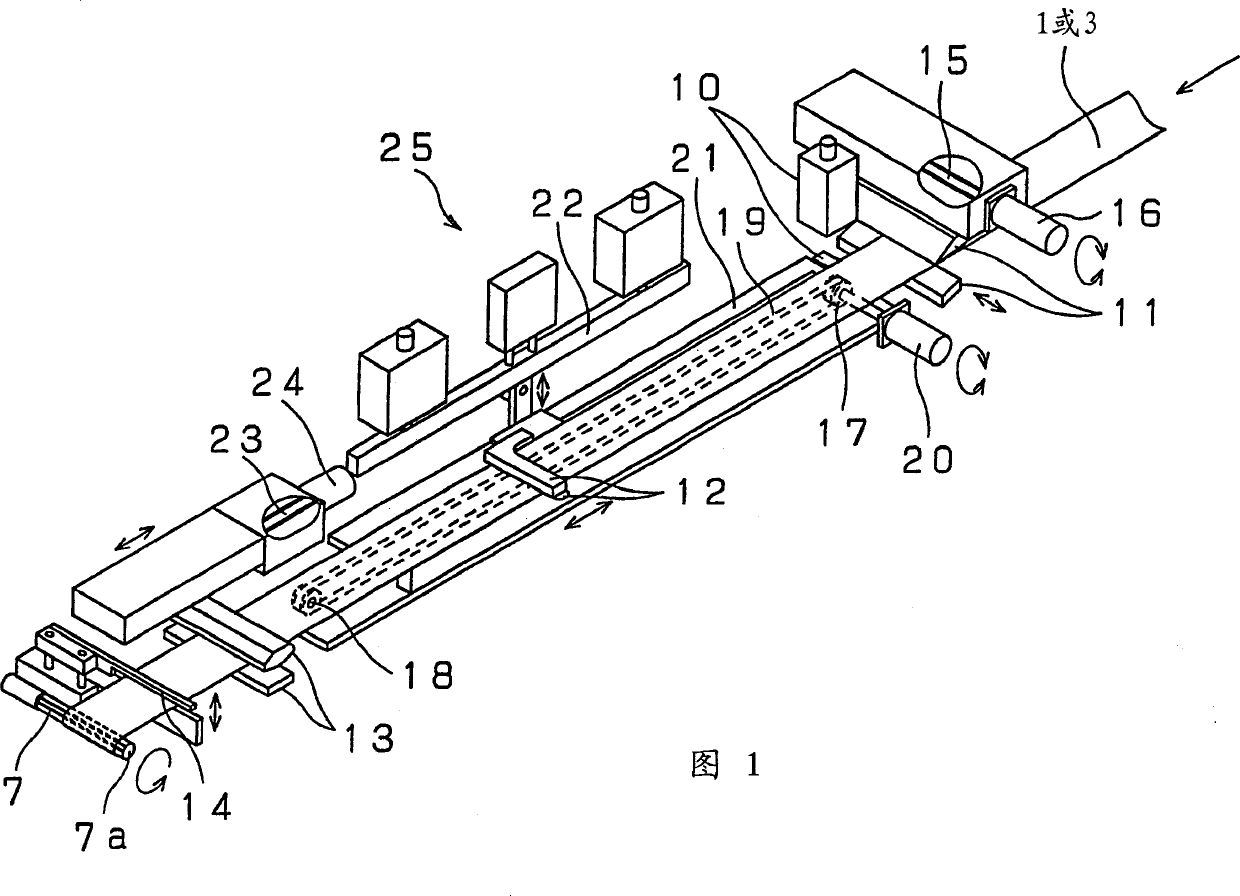

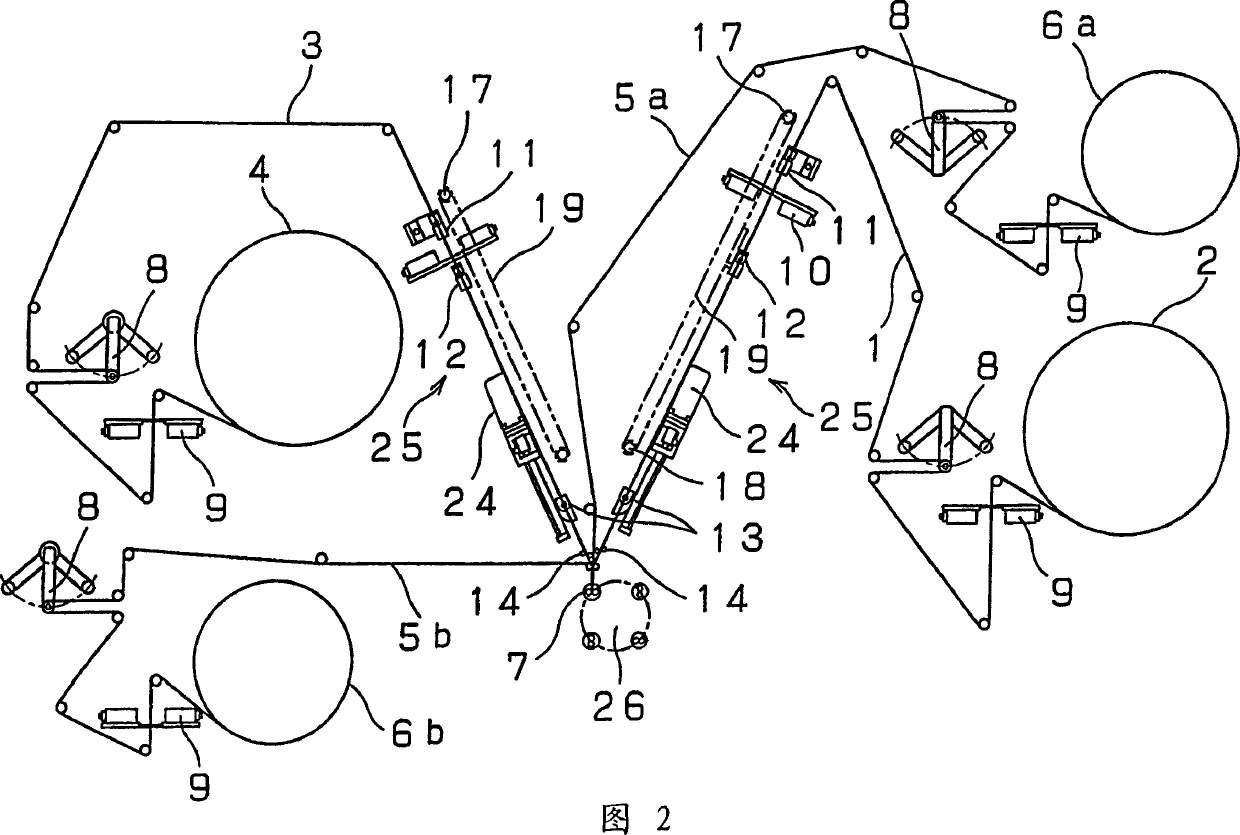

[0031] The embodiment of the winding method and device thereof for the battery spiral electrode group of the present invention is described below with reference to the accompanying drawings. The perspective view of the main part in the case (however, for the sake of understanding, only the positive electrode plate 1 or the negative electrode plate 3 is wound on the winding core 7, and other electrode materials are omitted to simplify the illustration). Fig. 2 is a diagram showing a schematic configuration of a winding device for a battery spiral electrode group according to the present invention.

[0032] In FIG. 2 , the positive and negative electrode plates 2 and 4 , the first separator plate 6 a and the second separator plate 6 b wound in rolls are respectively installed on a supply conveying shaft (not shown). And the winding device part is installed on a rotating disk 26, as shown in Figure 4, four axially perpendicular cross-sections are made into substantially hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com