Electric dust collector

A vacuum cleaner and electric technology, applied in the direction of vacuum cleaners, electric components, electromechanical devices, etc., can solve the problems of power increase and other problems, achieve the effects of shortening length, high air supply efficiency, and improving suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Figure 10 A perspective view showing the appearance of the electric vacuum cleaner related to Embodiment 1 of the present invention. exist Figure 10 Among them, 1001 is the main body of the vacuum cleaner with a built-in control circuit and electric blower, 1002 is a hose connected to the suction port of the main body 1001 of the vacuum cleaner, and 1003 is a hose handle connected to the hose 1002 at one end and held by the user at the same time. , 1004 is the extension tube connected to the other end of the hose handle 1003, 1005 is the suction port connected to the extension tube 1004, 1006 is the switch operation part set on the hose handle 1003, 1007 is set on the hose handle 1008 is the second infrared luminescent part arranged on the hose handle part 1003, 1009 is the infrared photosensitive part arranged on the vacuum cleaner main body 501, and 1010 represents the indoor ceiling.

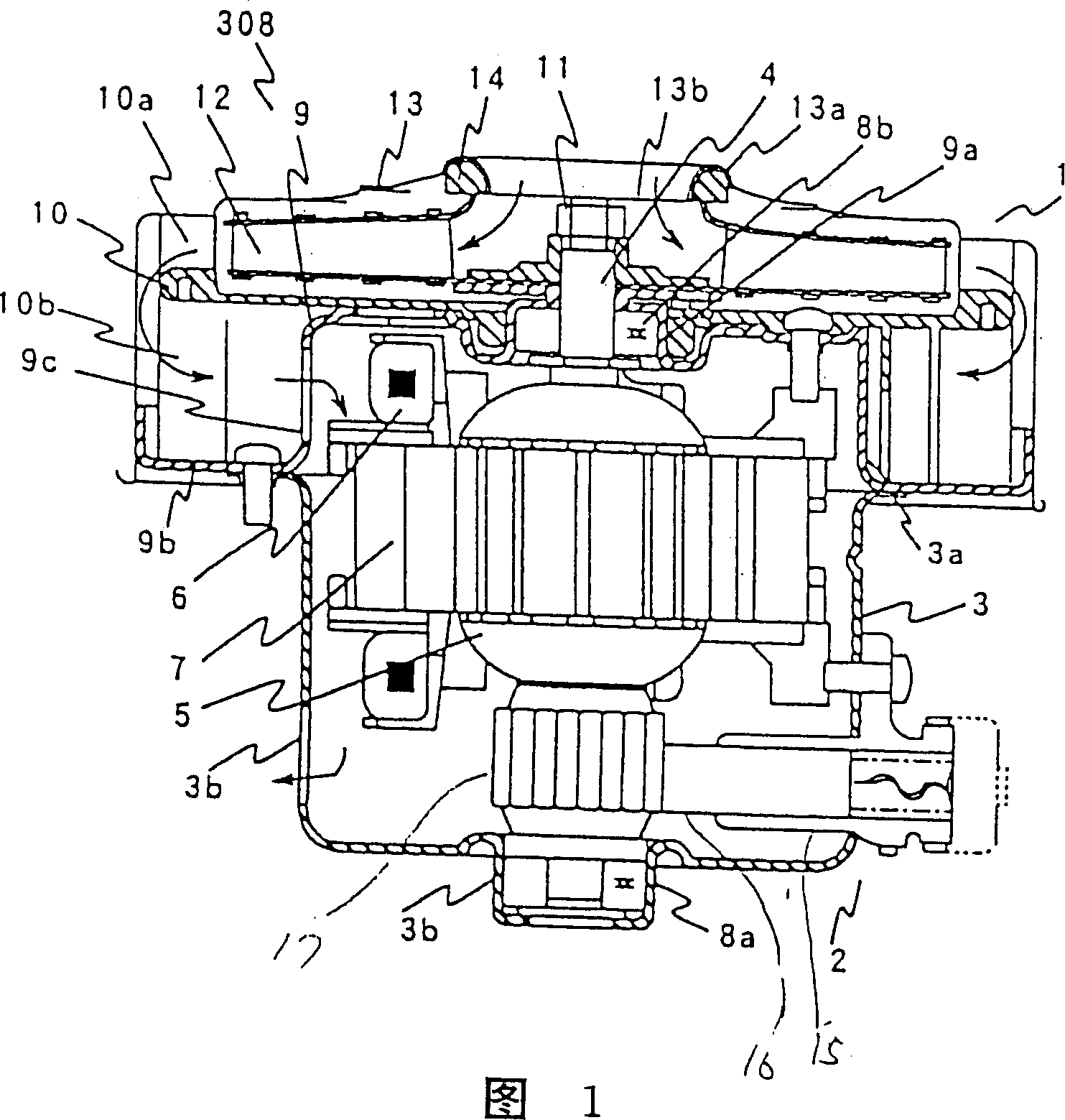

[0050] Figure 11 It shows a longitudinal sectional view of the electric vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com