Damping tools

A cutting tool and shock absorber technology, which is applied in the direction of cutting tools used in lathes, manufacturing tools, tool holder accessories, etc., can solve the problems of reducing the rotation speed, eccentricity of the counterweight part 102, changing viscosity, etc., and achieves the improvement of suppression of high frequency The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

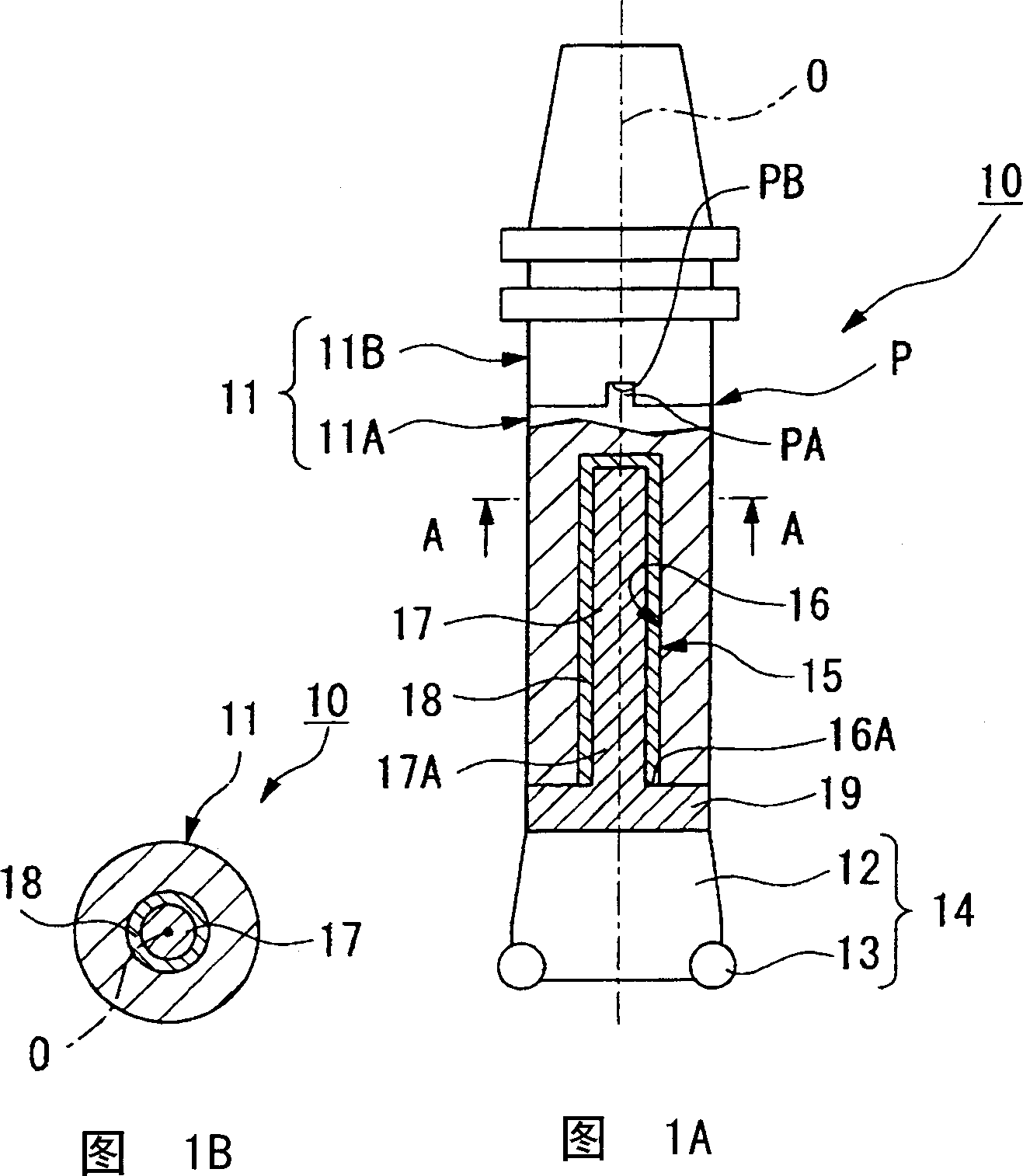

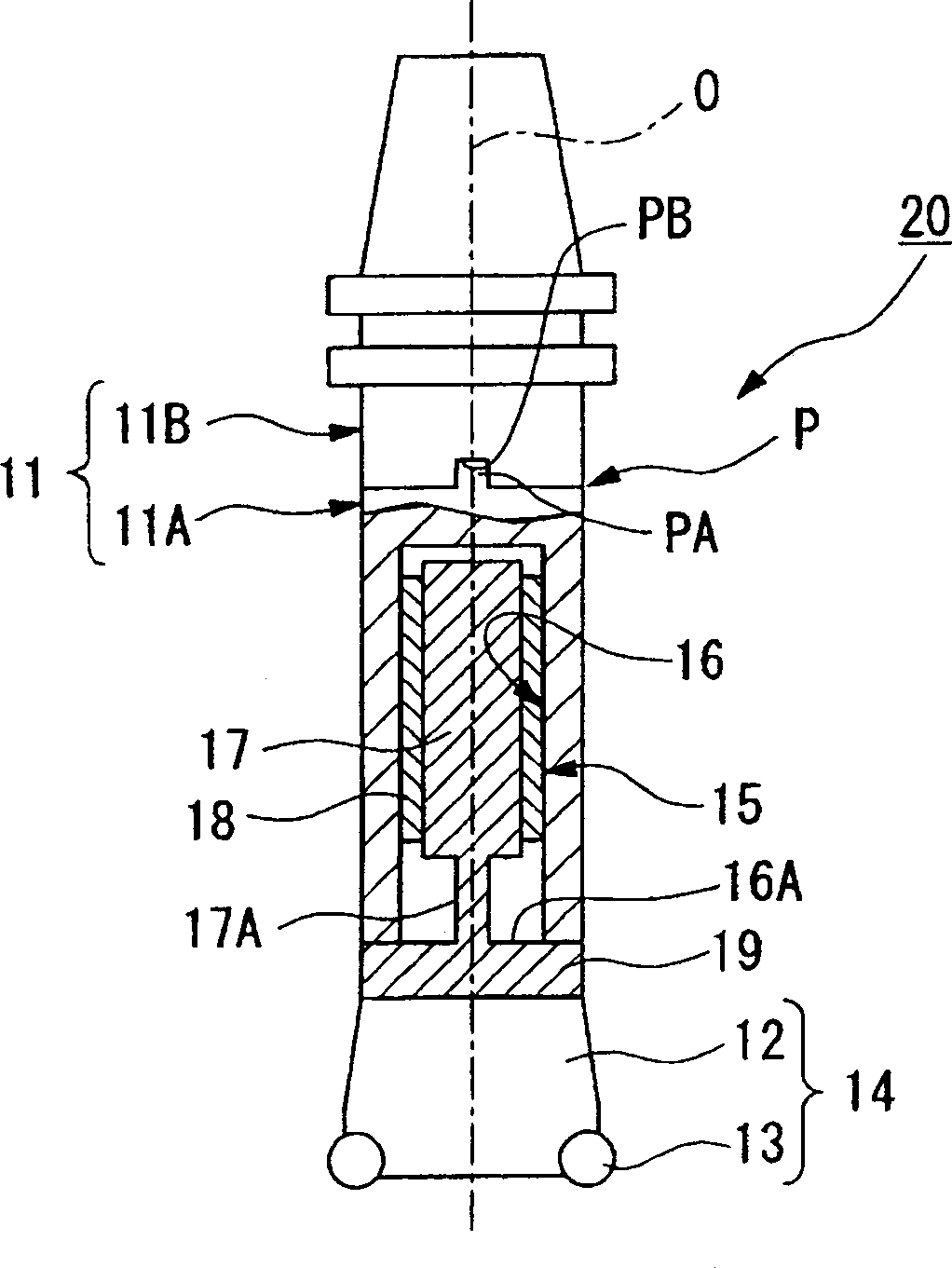

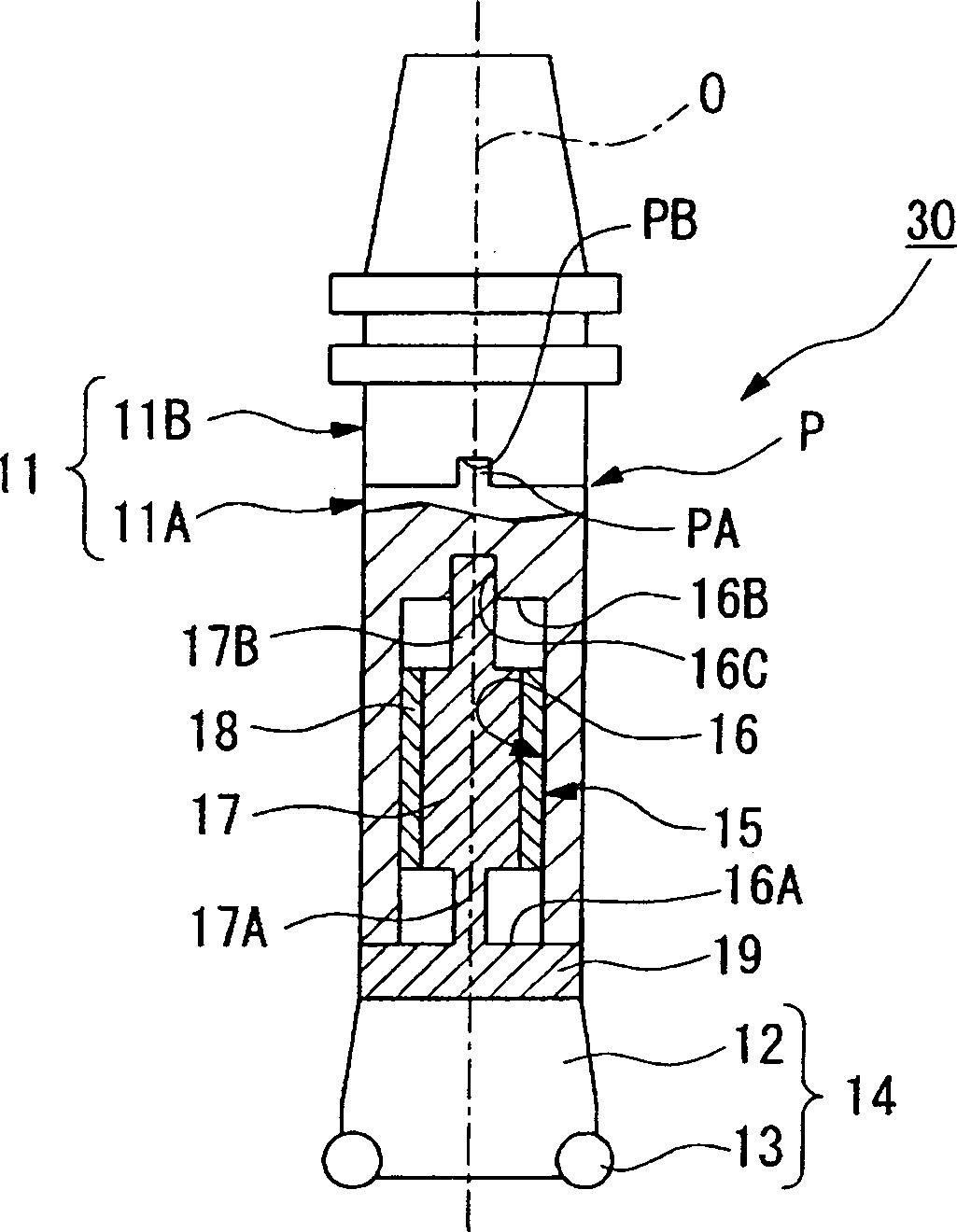

[0046] Fig. 1A is a partially cutaway side view of a vibration damping tool according to the first aspect of the present invention; Fig. 1B is a sectional view along line A-A in Fig. 1A.

[0047] As shown in FIG. 1, a vibration-damping tool 10 according to a first embodiment is a rotary cutting tool mainly formed of a tool body 11 and a head portion 14 (ie, cutting means). The body 11 is made, for example, of steel and has a bottom end supported in a cantilevered manner on the clamping portion of the machine tool. The tool body 11 is substantially cylindrical and rotates about the axis O. A plurality of throwaway blades 13 are installed on the outer circumference of the top of the head body 12 of the head 14 .

[0048] As shown in FIG. 1 , the head 14 is detachably mounted on the top end of the tool body 11 by means of fastening screws (not shown in the figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com