Hollow decorative PVC gusset and its production process

A production method and technology of PVC materials, which are applied to objects with hollow walls, building components, applications, etc., can solve the problems of flammability, inapplicability, and easy damage, and achieve simple production methods, wide application range, and not easy to be damaged. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

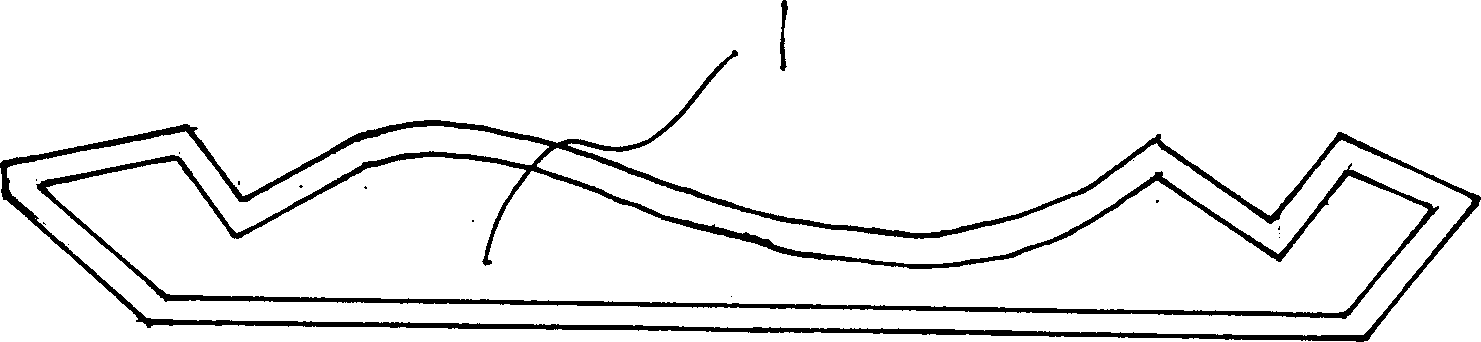

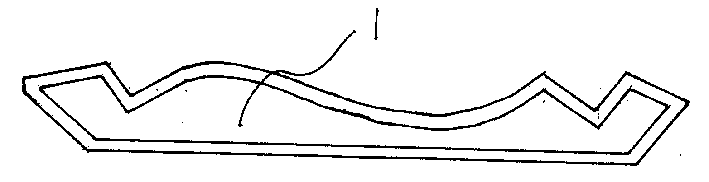

[0015] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. figure 1 Shown is a hollow trim molding made of PVC material. Its PVC material can be made of 8 kilograms of polyvinyl chloride, 8 kilograms of chemical coloring additives, 8 kilograms of three-salt mechanical lead sulfate, 8 kilograms of hard acid, 8 kilograms of hard lead, 8 kilograms of hard barium, and 8 kilograms of two new Barium and 15 kg of calcium heavy acid powder mixed. It can also be composed of 15 kg of polyvinyl chloride, 15 kg of chemical coloring additives, 15 kg of three-salt mechanical lead sulfate, 15 kg of hard acid, 15 kg of hard lead, 15 catties of hard barium, 15 kg of dinew barium and 22 kg Calcium heavy acid powder is mixed.

[0016] The specific production method is:

[0017] First, mix the raw materials according to the above materials; put the mixed materials into the plastic extruder, the temperature of the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com