Compound liquid-crystal micro-lens for sensor

A liquid crystal lens and lens technology, which is applied in the direction of lens, instrument, image data processing, etc., can solve the problems that cannot be shortened and increase production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

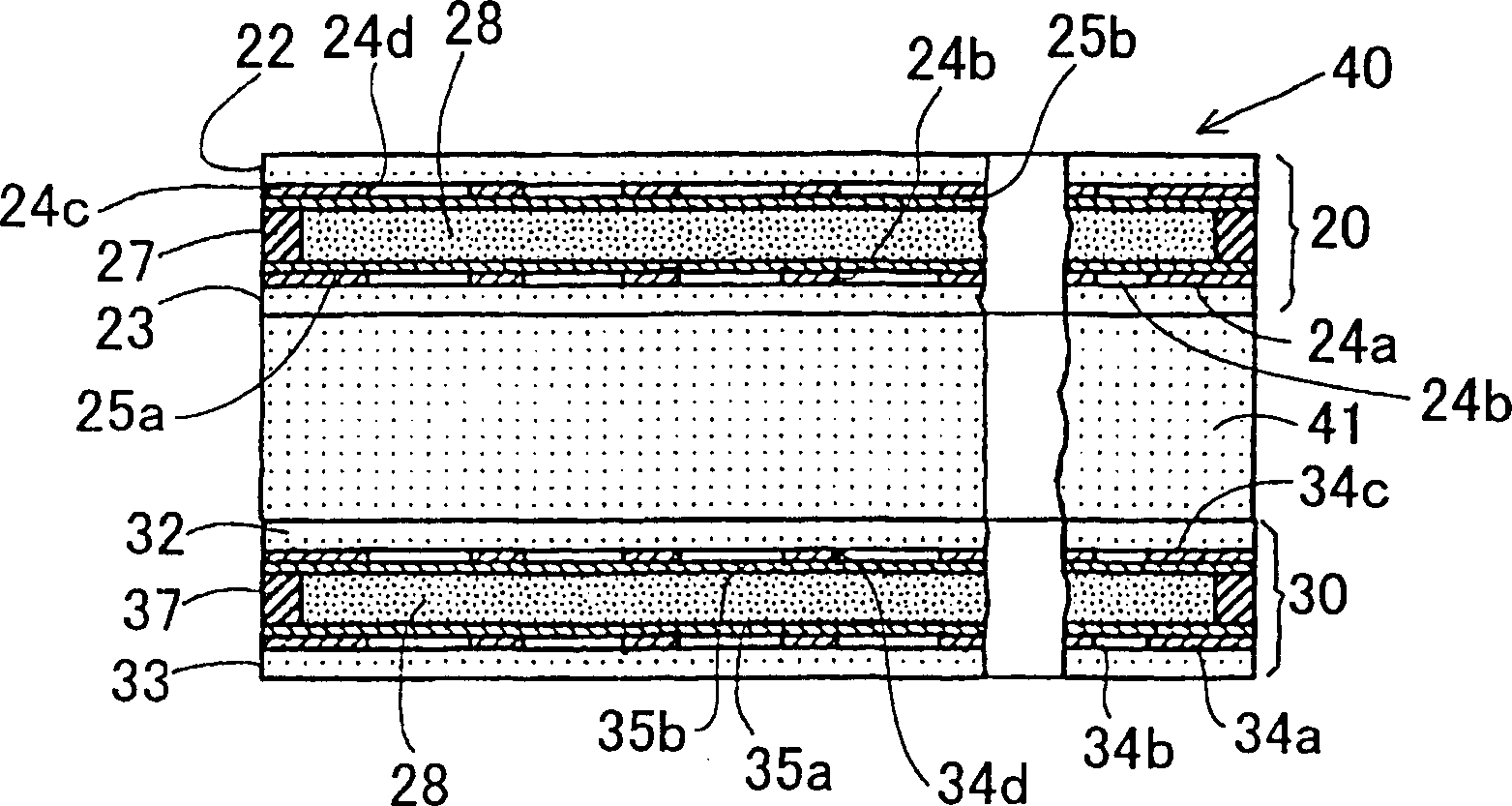

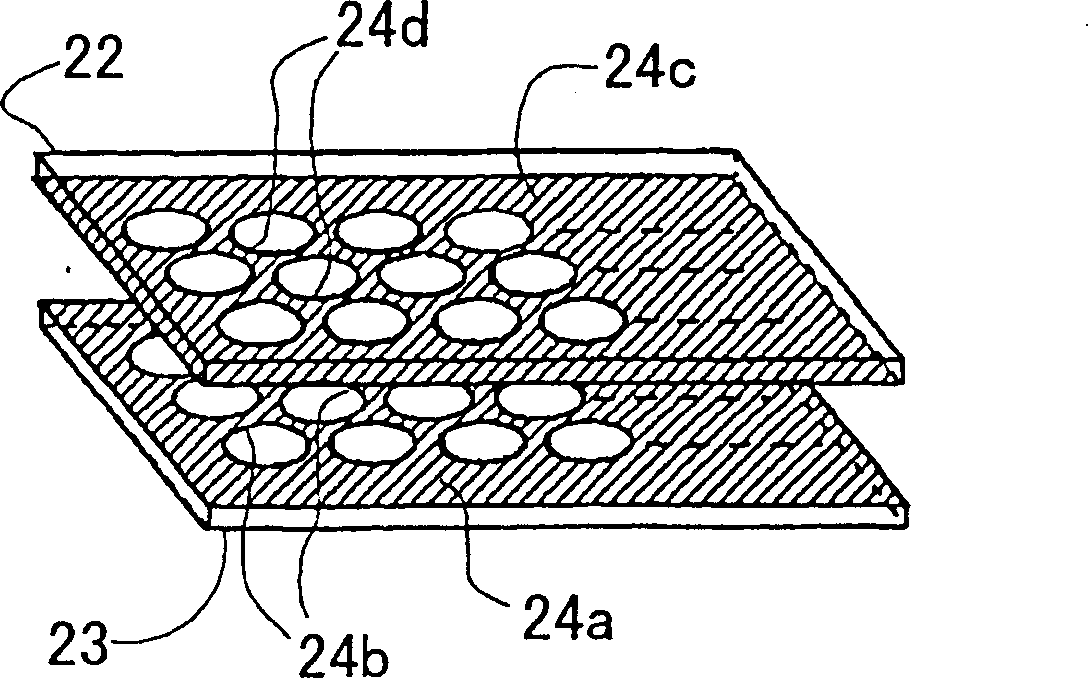

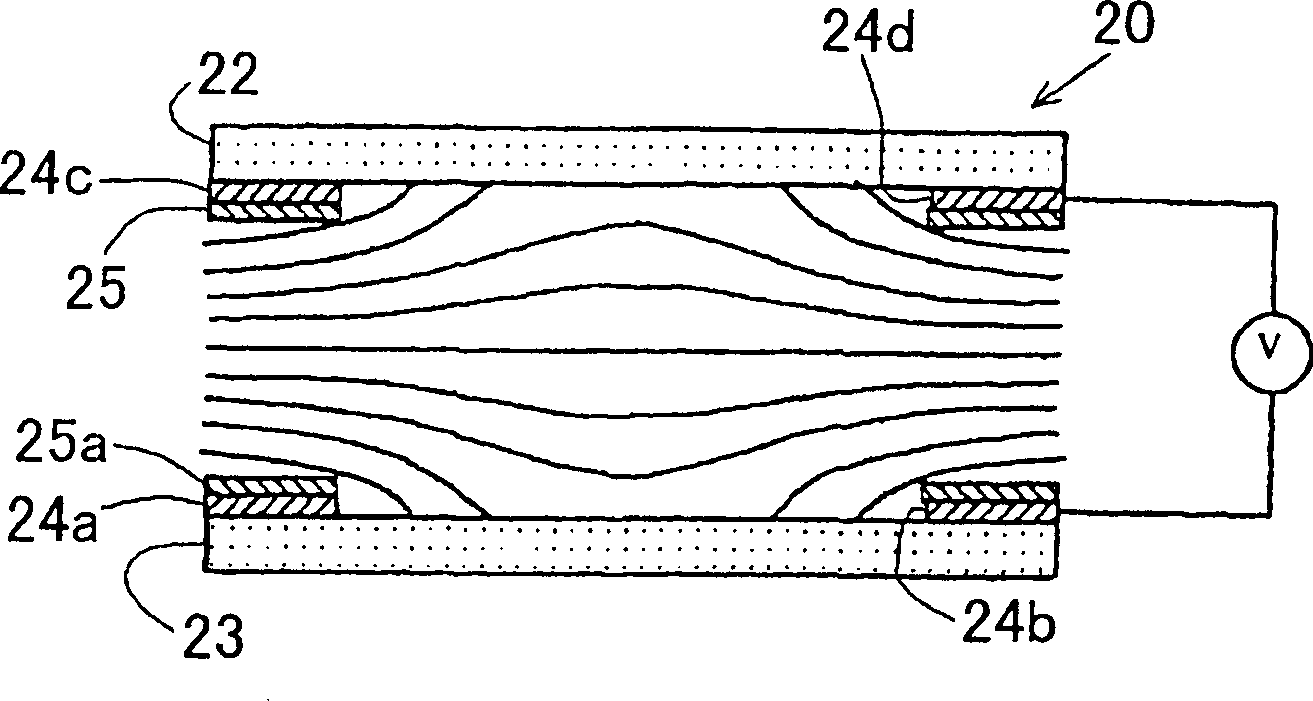

[0045] First, explain the liquid crystal lens in general. The structure and characteristics of a liquid crystal lens are described in the known publication OplusE. October 1998, Vol. 20, No. 10, Kabushiki Kaisha Shingijutsu Communication, with the characteristics of a liquid crystal optical element and its application: liquid crystal microlens. The content of the article will be described below.

[0046] In order to form an optical element used as a lens with liquid crystal, the liquid crystal layer that becomes the medium is shaped into the lens, as in a glass lens. On the other hand, an optical element can be configured so that a spatial refractive index can be imparted. In a nematic liquid crystal cell, liquid crystal molecules are aligned in the direction of an electric field. Thus, due to the symmetrical and non-uniform distribution effect of the liquid crystal molecules in the electric field about the axis, a lens with a spatial refractive index distribution can be pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com