X zeolite preparation

A zeolite and nano-technology, applied in the direction of crystalline aluminosilicate zeolite, fauhhedral crystalline aluminosilicate zeolite, etc., to achieve the effect of improving the environment and reducing waste residue and mother liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the low silicon-aluminum ratio X zeolite provided by the present invention comprises:

[0014] (1) According to the chemical composition of the waste residue and / or mother liquor, add sodium hydroxide and potassium hydroxide mixed alkali and water glass and / or aluminum source into the catalyst plant waste residue and / or mother liquor according to the required feeding ratio, and mix well , so that the total molar composition of the resulting reaction mixture conforms to (4.0-6.0)Na 2 O:(1.0~2.5)K 2 O:Al 2 o 3 :(1.0~3.0)SiO 2 :(50~250)H 2 The ratio of O; among them, Al in waste residue and mother liquor 2 o 3 Accounting for the total Al of mixed material 2 o 3 0-50% by weight of the amount; SiO in waste residue and mother liquor 2 % of total SiO in mixed materials 2 15-100% by weight of the total alkali amount; the alkali in the waste residue and the mother liquor accounts for 0-45% of the total alkali amount;

[0015] (2) aging the mi...

Embodiment 1

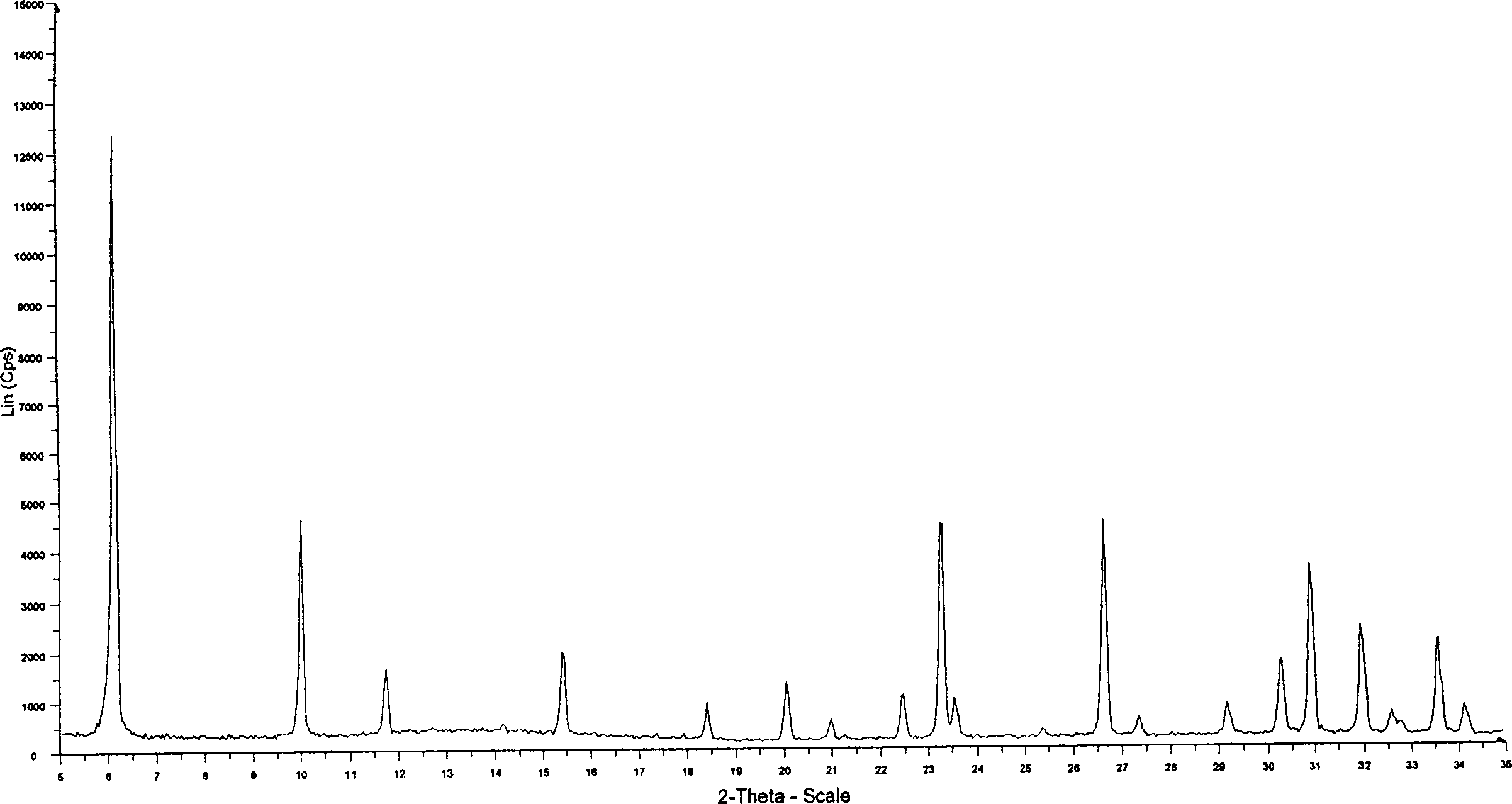

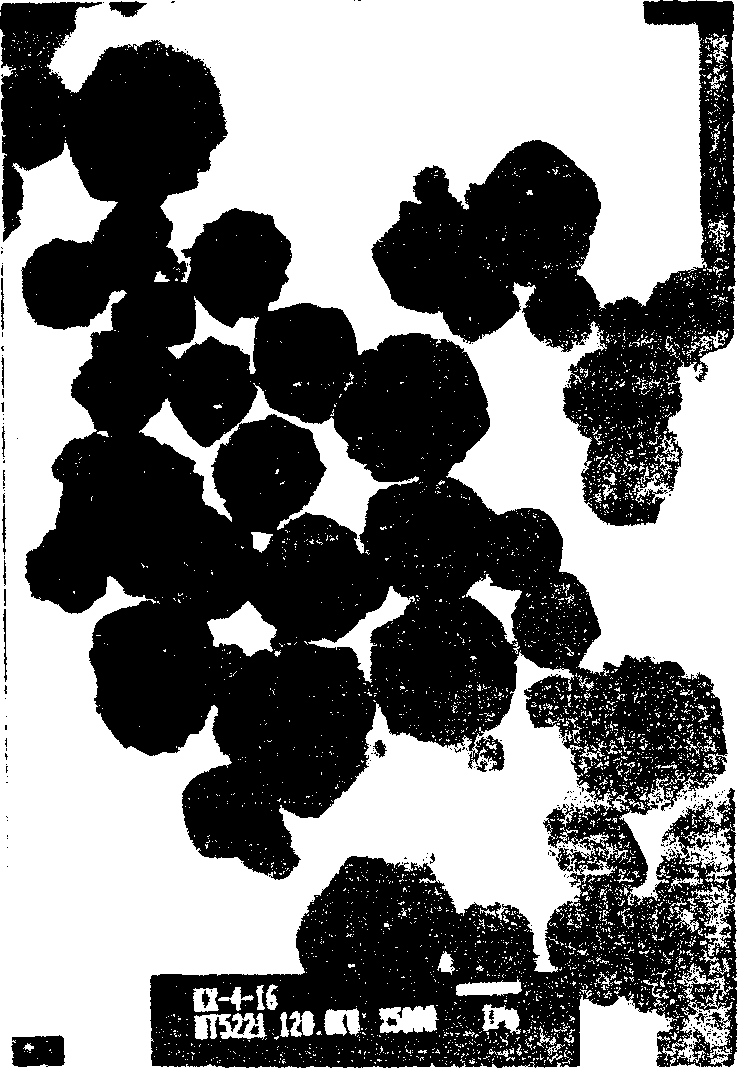

[0027] In the 880g waste residue (taken from the comprehensive workshop of Changling Catalyst Factory, Na 2 O=1.83%, SiO 2 =76%, Al 2 o 3 = 32.4%, RE 2 o 3 = 28%, SO 4 = = 1.14%, Fe = 0.046%, Cl - =0.3%, solid content=15.7%), add 310 milliliters of mother liquor (Na 2 O=47 g / L, SiO 2 =99 grams per liter), 710ml liquid caustic soda (NaOH, taken from Changling Catalyst Factory, Na 2 O=298 grams per liter), and 224 grams of KOH (chemically pure reagent, purity 82%, Beijing chemical plant), stir, after the solid alkali dissolves substantially, add 580 milliliters of low alkalinity sodium metaaluminate solutions (Na 2 O=147 g / L, Al 2 o 3 =90 g / L), stirred evenly, put into a stainless steel reactor and aged at 40°C for two days, crystallized at 70°C for 16 hours, filtered, washed, and dried. The unit cell constant of the resulting product is 2.501 nanometers, and the chemical composition of the product is Na 2 O=13%, K 2 O=12%, SiO 2 =41%, Al 2 o 3 = 33%, RE 2 o 3...

Embodiment 2

[0032] In 860g waste residue (same as above, Na 2 O=6.7%, SiO 2 =66.9%, Al 2 o 3 = 18.6%, RE 2 o 3 =0.47%, Fe 2 o 3 = 0.25%, SO 4 = =5.2%, Cl - =0.30%, solid content 18.3%), add 300 milliliters of mother liquors (same as above, Na 2 O=40 g / L, SiO 2 =87 grams per liter), 650ml liquid caustic soda (same as above, Na 2 (O=297 g / liter), 220 gram KOH (same as above), 10 grams of X zeolite product gained in Example 1, stir, and add 730 milliliters of low alkalinity sodium metaaluminate (same as above, Na 2 O=152 g / L, Al 2 o 3 = 100 g / L), stirred evenly, put into a stainless steel reactor and aged at 30°C for three days, crystallized at 60°C for 24 hours, filtered, washed, and dried. The resulting product unit cell constant is 2.501 nanometers, and the chemical composition of the product is Na 2 O=14%, K 2 O=11%, SiO 2 =41%, Al 2 o 3 = 34%, RE 2 o 3 =0.15%, Fe 2 o 3 =0.1%, benzene adsorption capacity 170mg / g, whiteness 83%, specific surface area 590m 2 / g, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com