Light reflective sunshading and thermal insulating composite film

A composite film, sunshade and heat preservation technology, which is applied in the field of laminated products, can solve the problems of reducing reflection cooling performance, increasing energy consumption, and losing the purpose of sunshade, etc., and achieves the effect of improving the ability to resist natural degradation, prolonging the service life, and achieving remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

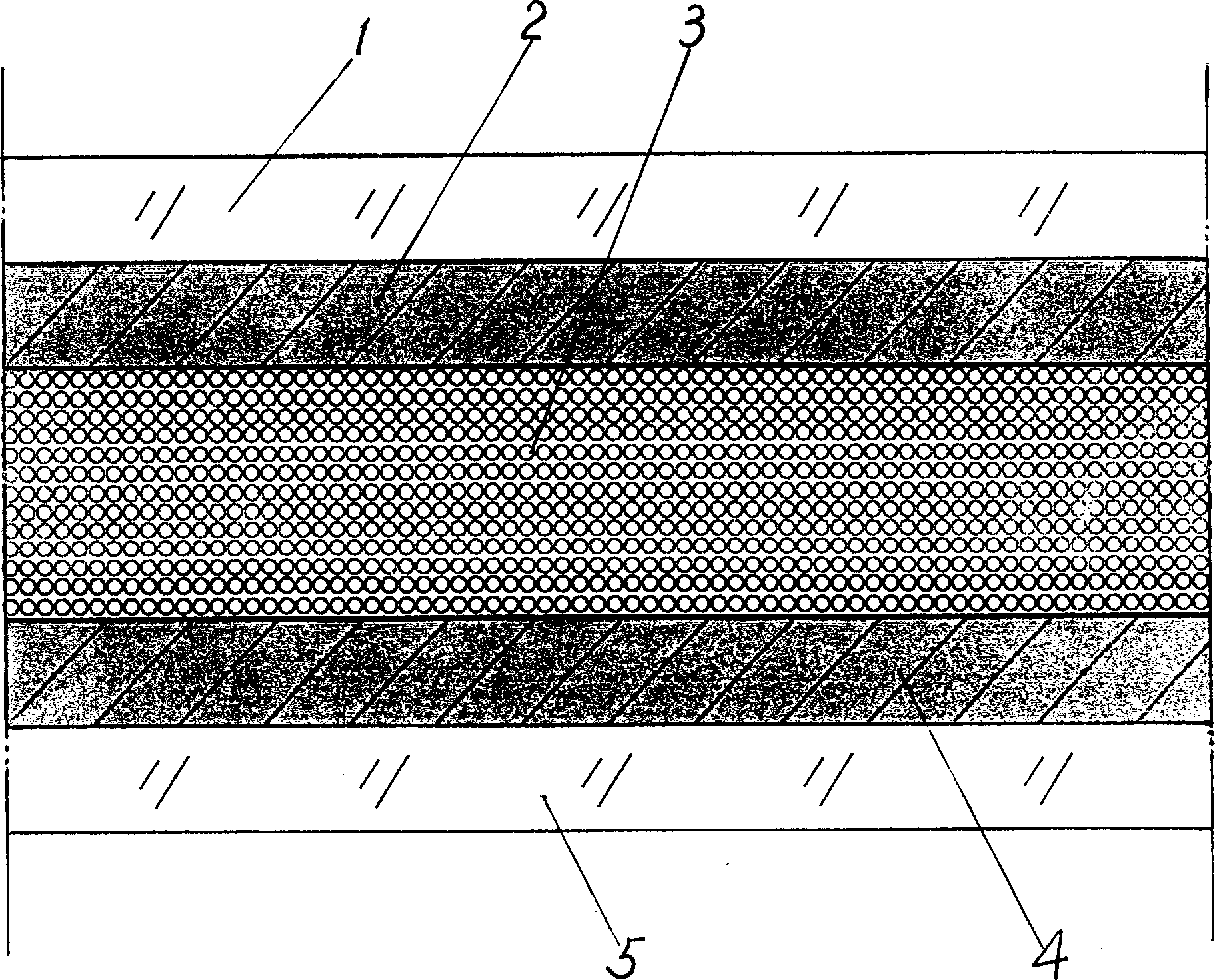

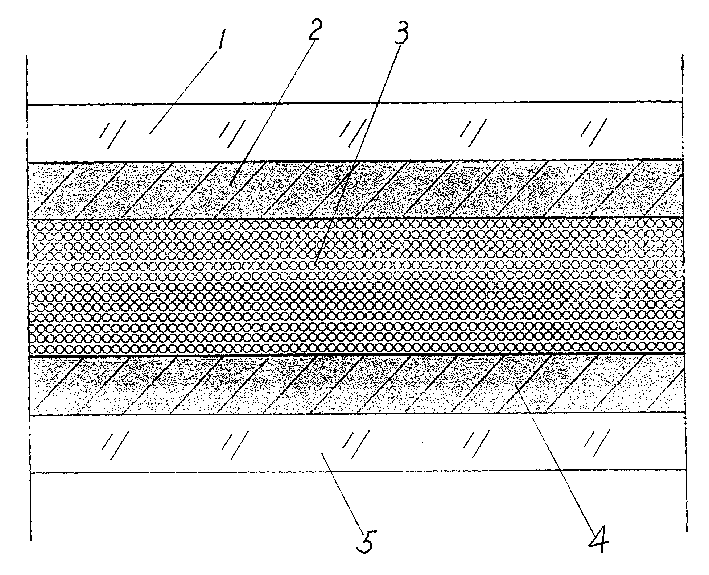

[0013] As shown in the drawings, the present invention comprises an aluminum layer divided into an upper aluminum layer 2 and a lower aluminum layer 4, and a transparent film 1 covering the outer surface of the upper aluminum layer 2. The transparent film 1 is polyethylene (PE), polyvinyl chloride (PVC) or polyester (PET) plastic film with high light transmittance. In consideration of the cost of the product and the prevention of ultraviolet rays, it is preferred to use uniaxially stretched polyethylene film plastic (OPE) with anti-pesticide anti-ultraviolet additives as the transparent film 1 . A microporous foam layer 3 is arranged between the upper aluminum layer 2 and the lower aluminum layer 4 . The microporous foaming layer is made of polyethylene and polyvinyl chloride added with foaming aids through a foaming process, and the foaming amount is 25 to 35 times. A transparent protective layer 5 is provided on the other side of the lower aluminum layer 4 . This transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com