Linearly liquid collecting redistributor

A liquid collection and liquid distribution technology, which is applied in the direction of distillation separation, separation methods, chemical instruments and methods, etc., can solve the problems of complex structure of the collector, small gas channel, poor separation effect, etc. Effect of exchange and prevention of clogging by solid matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

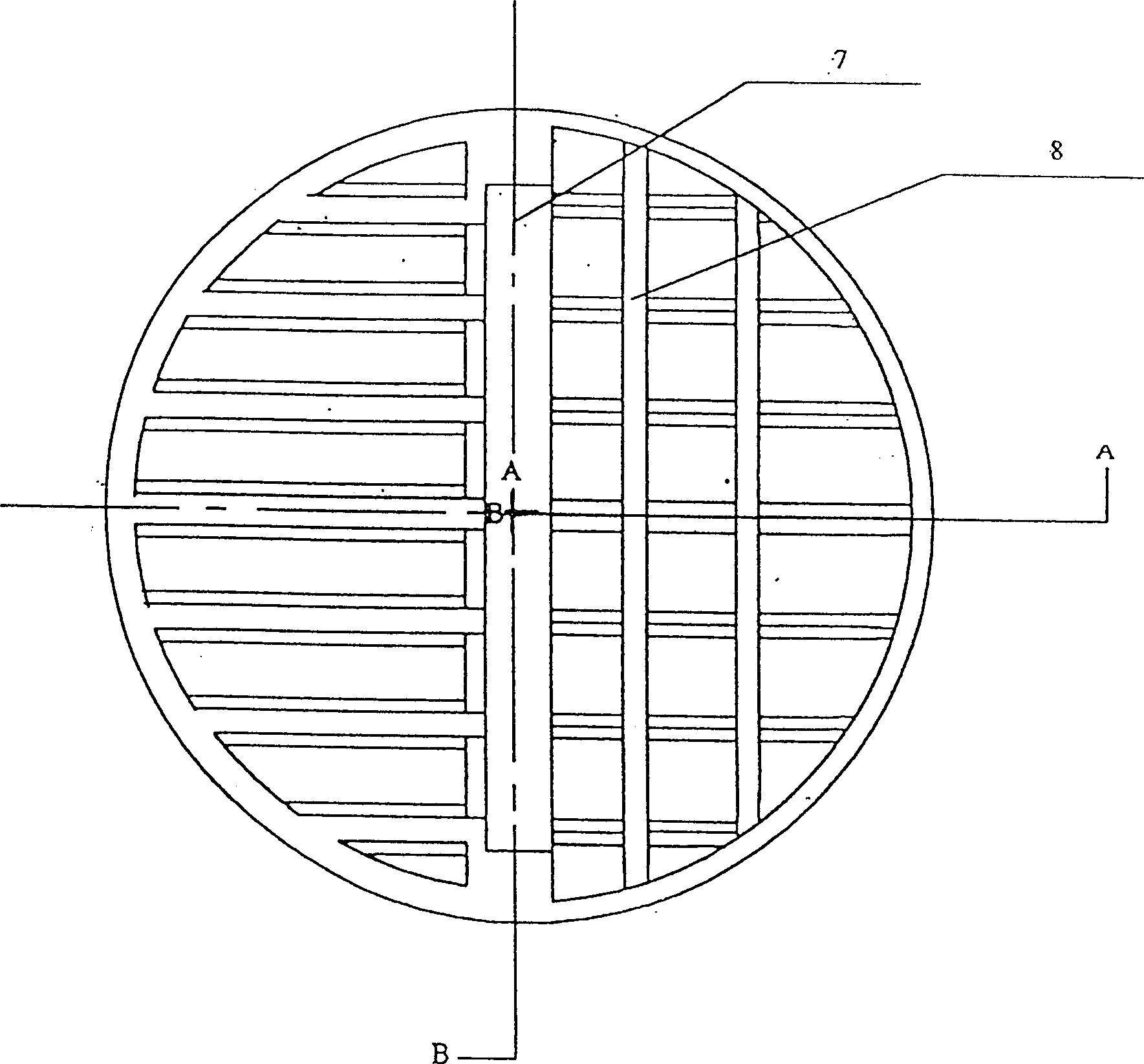

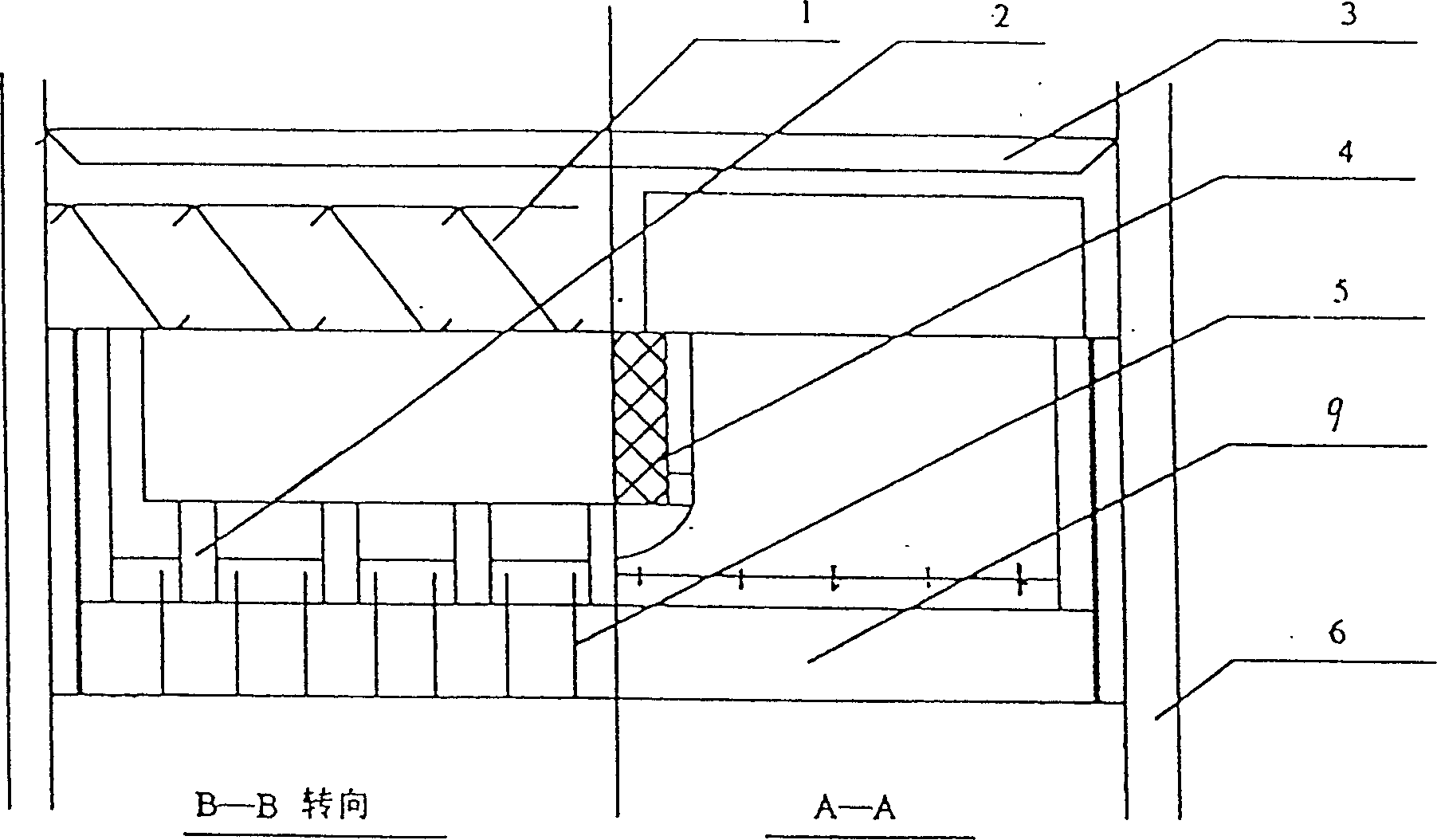

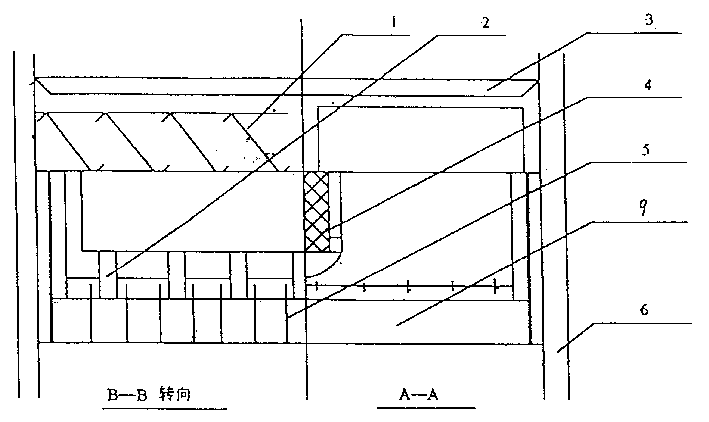

[0012] The present invention adopts the downcomer plate 5 and the downcomer ring 9 to be combined into one, placed between the filler and the liquid distribution groove 2, the lower part of which is directly pressed on the filler, and directly fixed on the tower wall 6 by bolts, which can play a role Compress the filler, and the downcomer plate acts as a liquid film generator. The part of the liquid distribution groove adopts the groove type set type, and several liquid distribution grooves 2 rest on the material ring 9 for reducing the hydraulic pressure, and the middle primary groove 7 is installed inside the liquid distribution groove 2, and the bottom of the middle communication part is designed as an R shape, which can Reduce the resistance of gas rising. Liquid flow distribution holes are formed on the liquid distribution groove 2 . Most of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com