Deep negative pressure high-efficiency low-temp. water discharge crossflow cooling tower

A cooling tower, cross-flow technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of increased failure rate of refrigerator operation, increased exhaust air volume of cooling towers, and reduced safety factor and other issues, to achieve the effect of improving the comprehensive energy saving effect, reducing the operating current and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

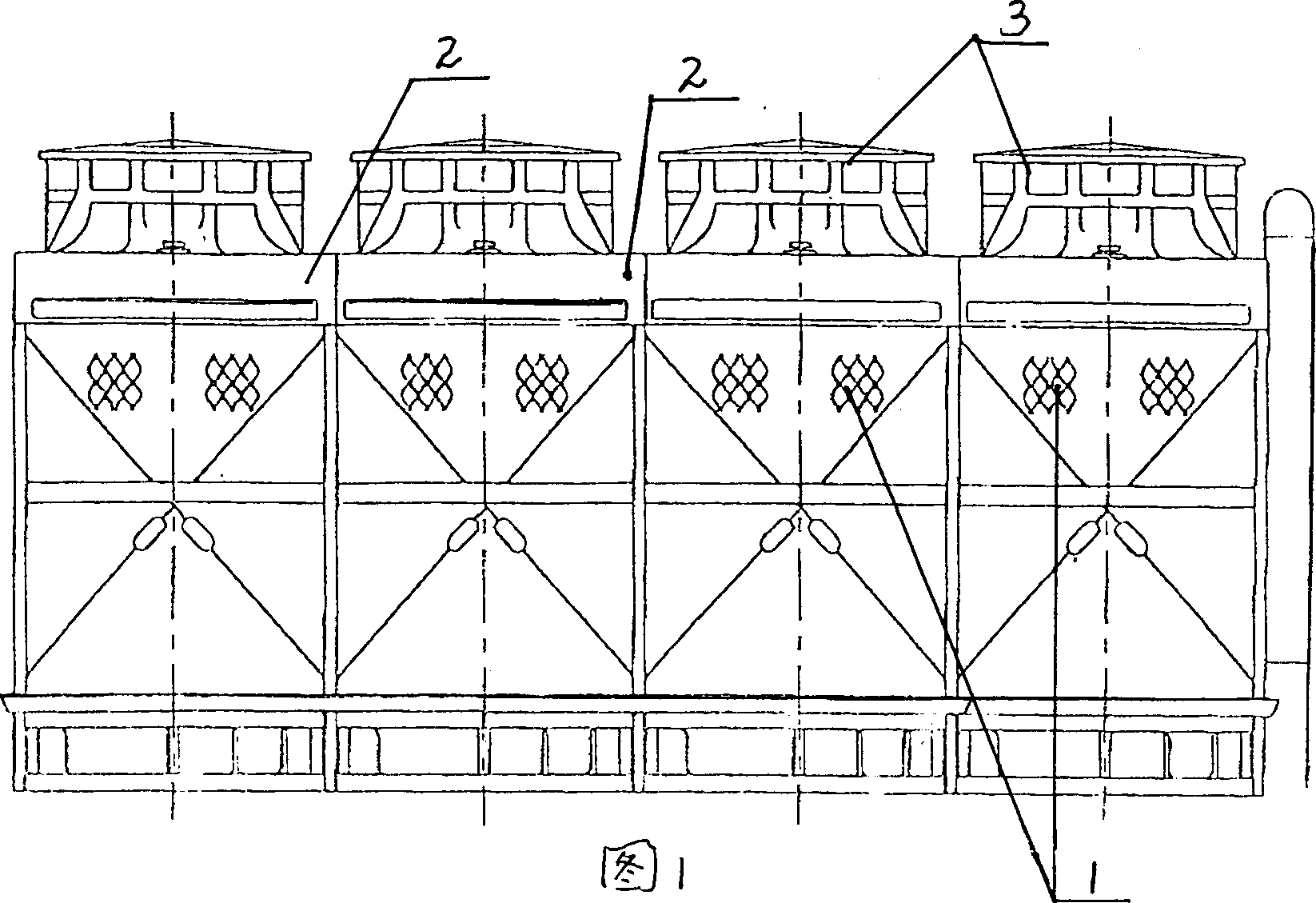

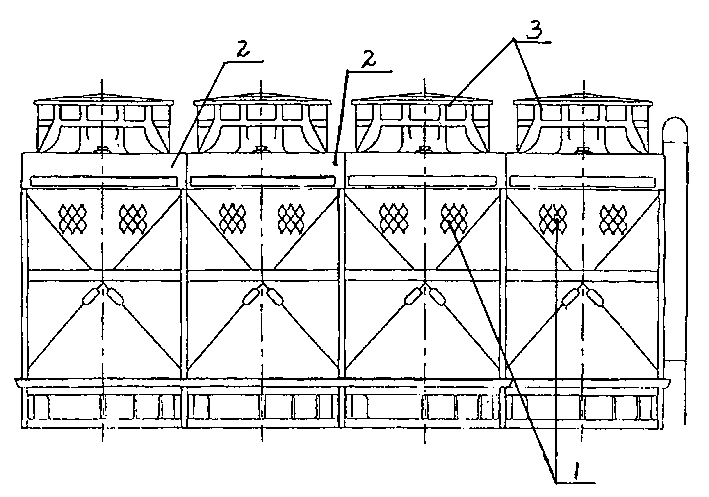

[0026] Choose the Sino-US joint venture Marley SC-150L tower type, and assemble every 4 sets into a cooling tower of the model TSC-500ML (see Figure 1). A total of 6 sets of TSC-500ML cooling towers are assembled and improved at the same time:

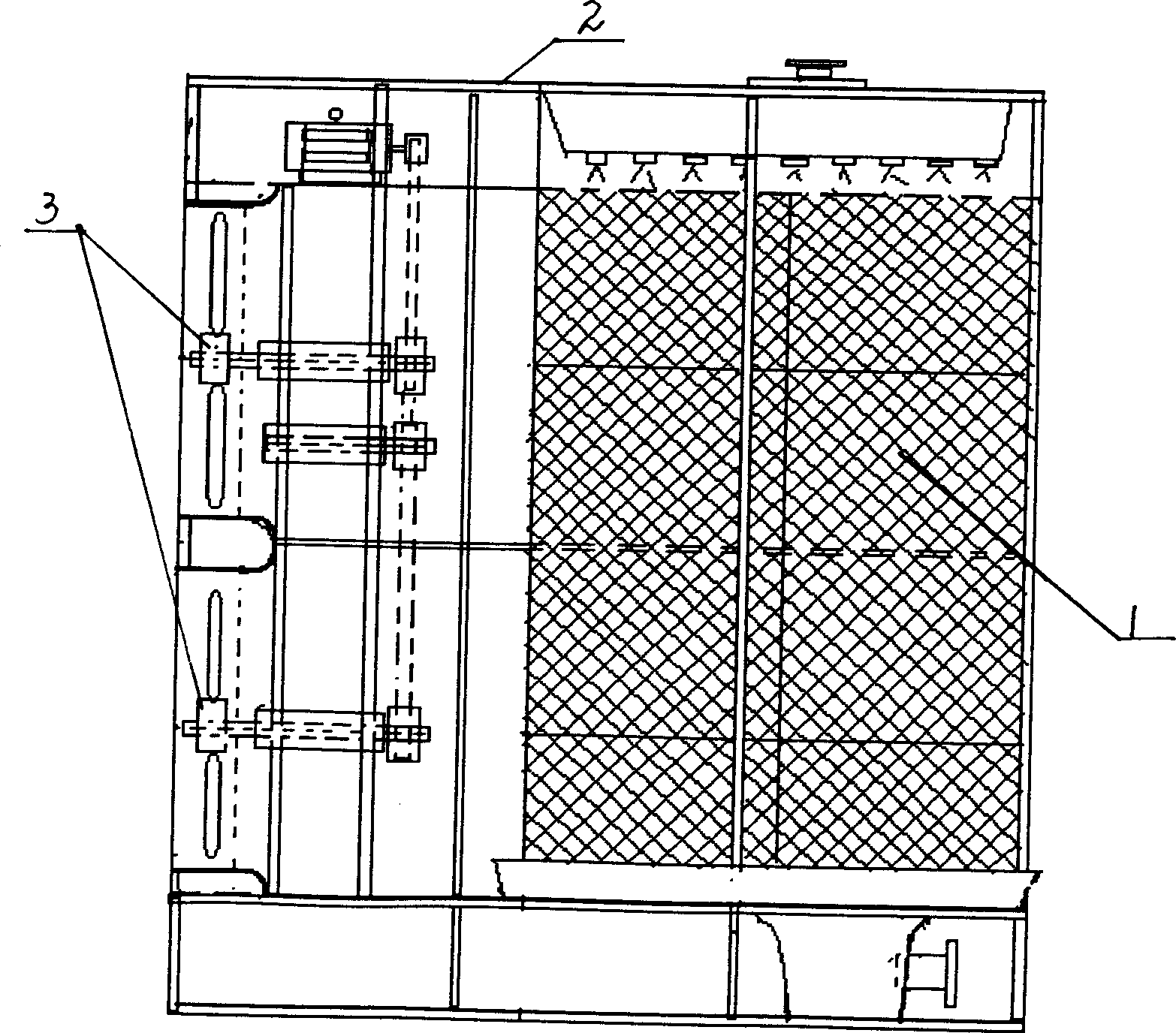

[0027] 1. Change the power of cooling tower fan 3 from 5.5kw to 7.5kw, increase the angle of fan blades, and increase the total exhaust air volume from 330000M 3 / h, increased to 440000M 3 / h or so. Increase the exhaust air volume by 33%. Make the pressure drop between the inlet and outlet of the heat sink in the cross-flow cooling tower reach 5-50 mm water column.

[0028] 2, the filler 1 in the above-mentioned cooling tower (it is positioned at both sides in tower body 2) widens 10% (total filler is greater than 20% when adding combination), filler 1 area increases about 40% than rated area.

[0029] 3. Since the area of the air inlet of the cooling tower increases by 20%, and the air intake is greater than 20% of the rated amou...

Embodiment 2

[0034] Choose the Sino-US joint venture Marley SC-150L tower type, and assemble every 4 sets into a cooling tower of the model TSC-500ML (see Figure 1). A total of 6 sets of TSC-500ML cooling towers are assembled and improved at the same time:

[0035] 1. Change the power of cooling tower fan 3 from 5.5kw to 9kw, increase the angle of fan blades, and increase the total exhaust air volume from 330000M 3 / h, increased to 528000M 3 / h or so. Increase the exhaust air volume by 60%, so that the pressure drop between the inlet and outlet of the heat sink in the cross-flow cooling tower reaches 500-1000 mm water column, which increases the kinetic energy of water evaporation, reduces the gravitational force of water molecules, and accelerates the speed of water evaporation and strength. Its operating efficiency table is shown in Table 3.

Embodiment 3

[0037] Choose the Sino-US joint venture Marley SC-150L tower type, and assemble every 4 sets into a cooling tower of the model TSC-500ML (see Figure 1). A total of 6 sets of TSC-500ML cooling towers are assembled and improved at the same time:

[0038] 1. Change the cooling tower fan 3 to a high-efficiency impeller scroll type high-pressure fan with a power of 10kw and a total exhaust air volume of 330000M 3 / h, increased to 594000M 3 / h or so. Increase the exhaust air volume by 80%, so that the pressure drop between the inlet and outlet of the heat sink in the cross-flow cooling tower reaches 1500-1900 mm water column, which increases the kinetic energy of water evaporation, reduces the gravitational force of water molecules, and accelerates the speed of water evaporation and strength.

[0039] 2, the filler 1 in the above cooling tower is increased by 10%, widened by 80%, (total filler is greater than 20% when adding combination), and the area of filler 1 is increased by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com