Grating type filter with adjustable spectrum shape

A spectral shape and filter technology, applied in the field of optical applications, can solve the problems of increasing the cost of filter production, expensive mask plate, etc., and achieve the effect of simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

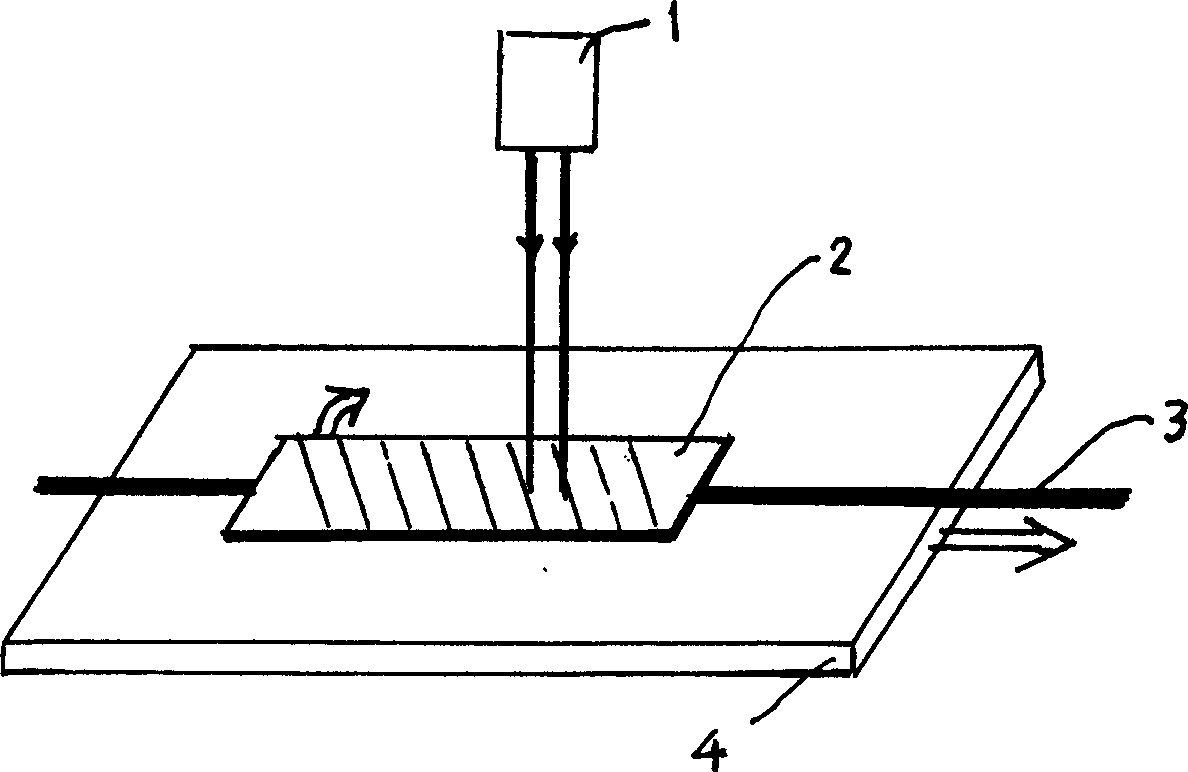

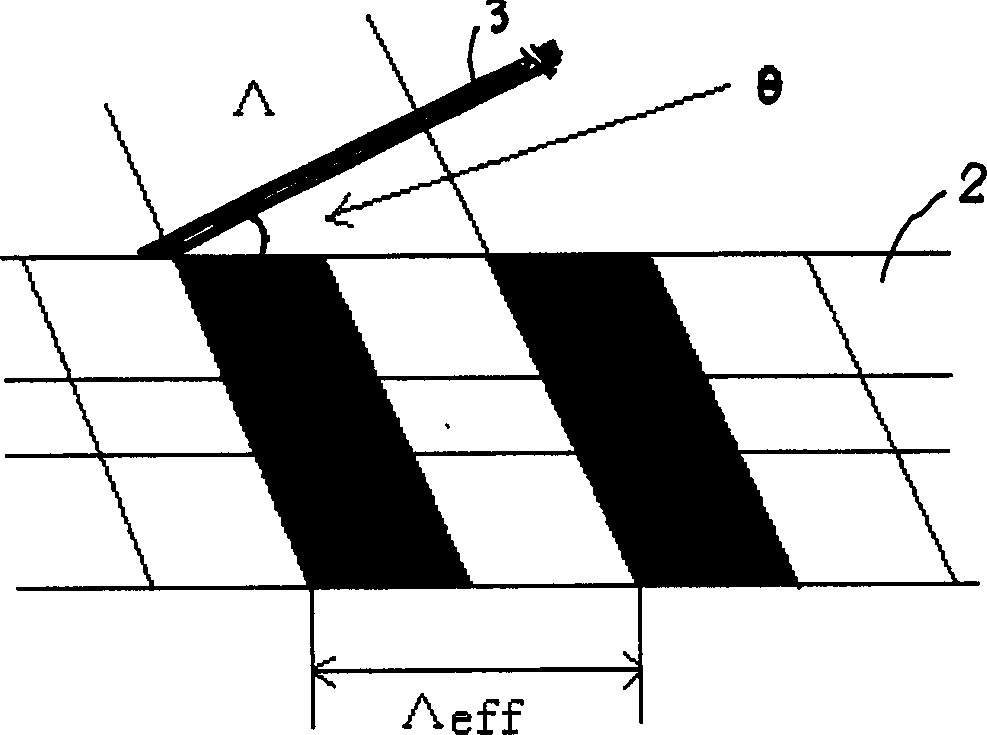

[0019] In the process of designing a grating filter with adjustable spectral shape, we use a stepping motor to control the relative rotation between the mask 2 and the optical fiber or waveguide 3 and the relative translation between the platform 4, the mask 2, and the laser beam. For this purpose, a stepper motor is also included in the structure. The stepping motor can drive the mask plate 2 or / and the platform 4 to rotate through the transmission device, and drive the platform 4, the mask plate 2, and the laser 1 to move in translation.

Embodiment 2

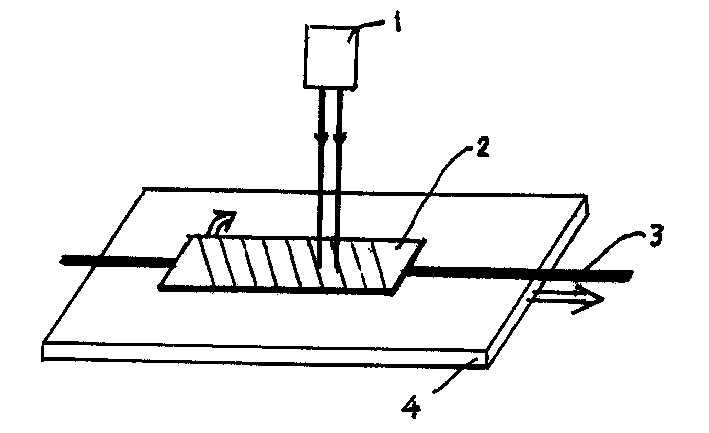

[0021] The relative rotation between the mask plate 2 and the optical fiber or waveguide 3 and the relative translation of the platform 4, mask plate 2, and laser beam can be controlled by a stepping motor, that is, the structure includes a computer control system. The computer control system controls the relative rotation of the mask 2 or / and the platform 4 , and controls the relative translation of the platform 4 , the mask 2 and the laser 1 .

[0022] Therefore, the production of grating filters has high precision and accuracy. When making grating filters with different spectral shapes, we don't need to change the mask, just change the control program of the computer to achieve the goal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com