Compensation method of current sensor and zero-flux microcurrent sensor

A technology of micro-current sensor and current sensor, which is applied in the direction of inductors, instruments, circuits, etc., can solve the problems that cannot be provided by the original current sensor, cannot track the excitation current in real time, static compensation, etc., and achieve good anti-electromagnetic interference ability, The effect of high reliability and low temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

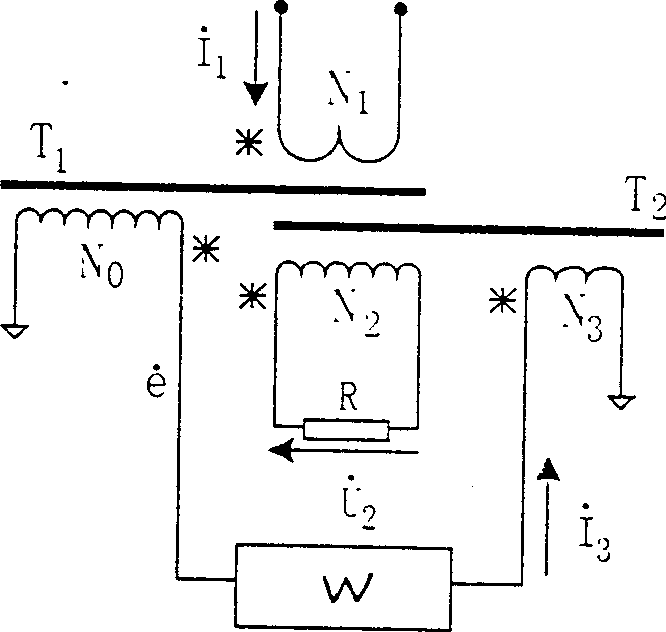

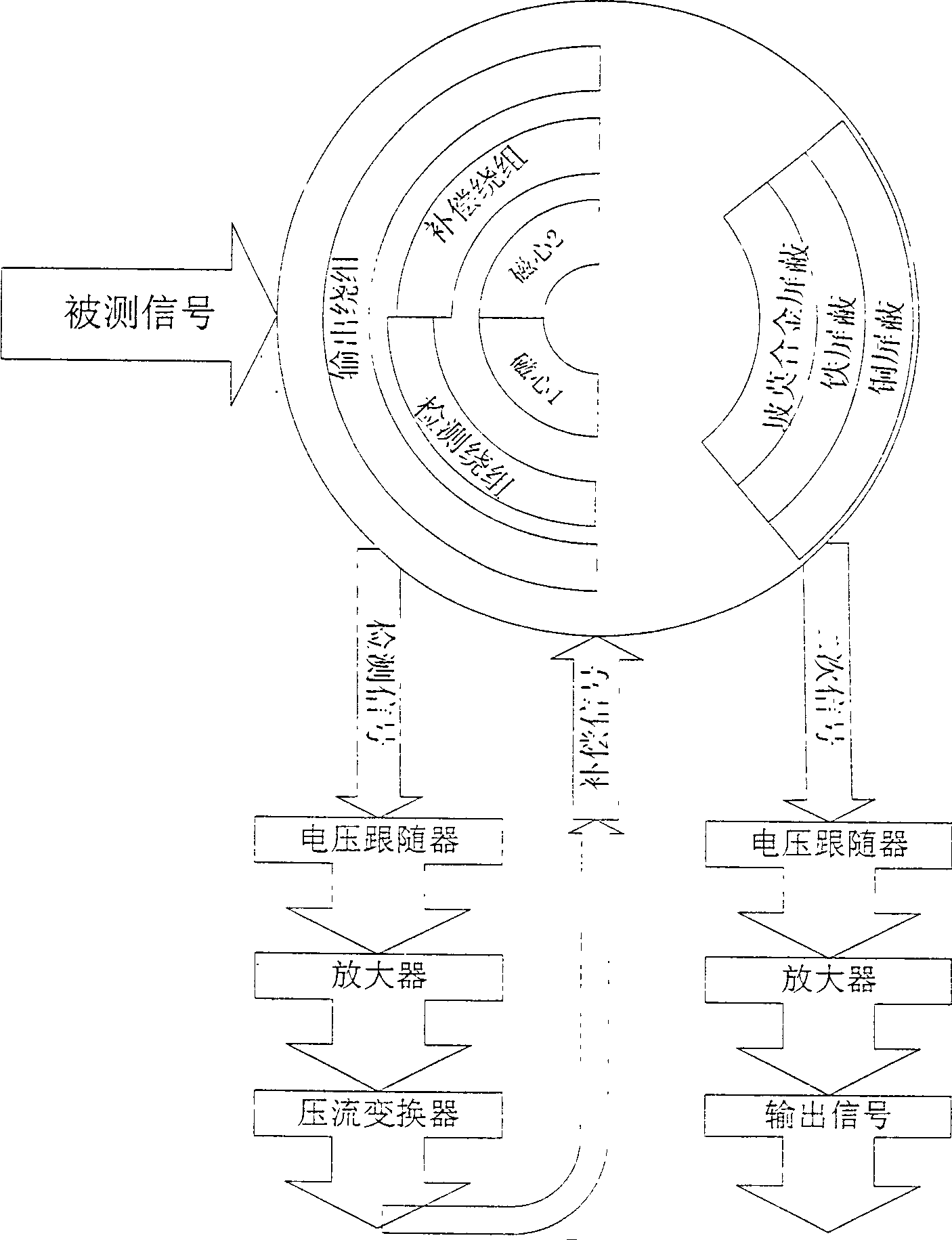

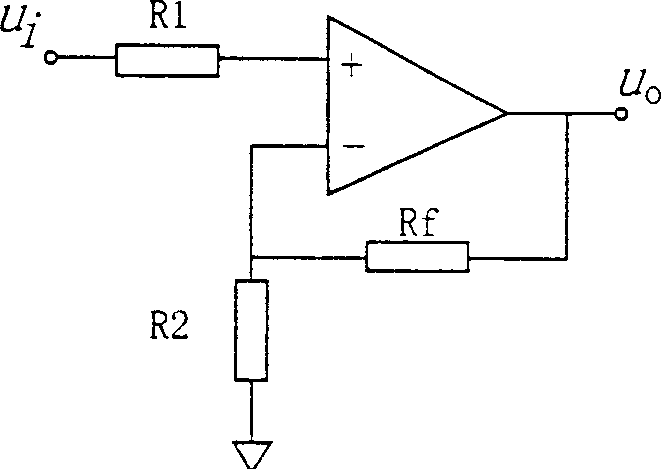

[0014] see figure 1 , the present invention adds a ring-shaped working magnetic core T on the basis of the ordinary current sensor 1 Auxiliary core T with the same shape and size 2 , the primary coil N after the two are superimposed 1 and secondary coil N 2 Wound on a laminated magnetic core, the secondary coil N 2 A load (such as a precision resistor R) is connected between the two ends of the circuit as a secondary current and then converted into a voltage signal and then amplified and output. The detection coil N 0 Wound on the working core T 1 On, compensation coil N 3 Wound on auxiliary core T 2 up, N 0 with N 3 An electronic conditioning circuit W is connected between them. Detection winding N 0 The role is to detect T 1 The magnetic density (magnetic induction intensity) in, provides the feedback voltage signal for the electronic conditioning circuit W, at N 0 There is no current in the winding, so for T 1 I will not appear when listing the balance equatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com