Sludge powdering method and special dewatering apparatus thereof

A treatment method and powdering technology, which can be used in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., and can solve problems such as large energy consumption, secondary pollution, and large space. , to achieve the effect of reducing cost and high dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

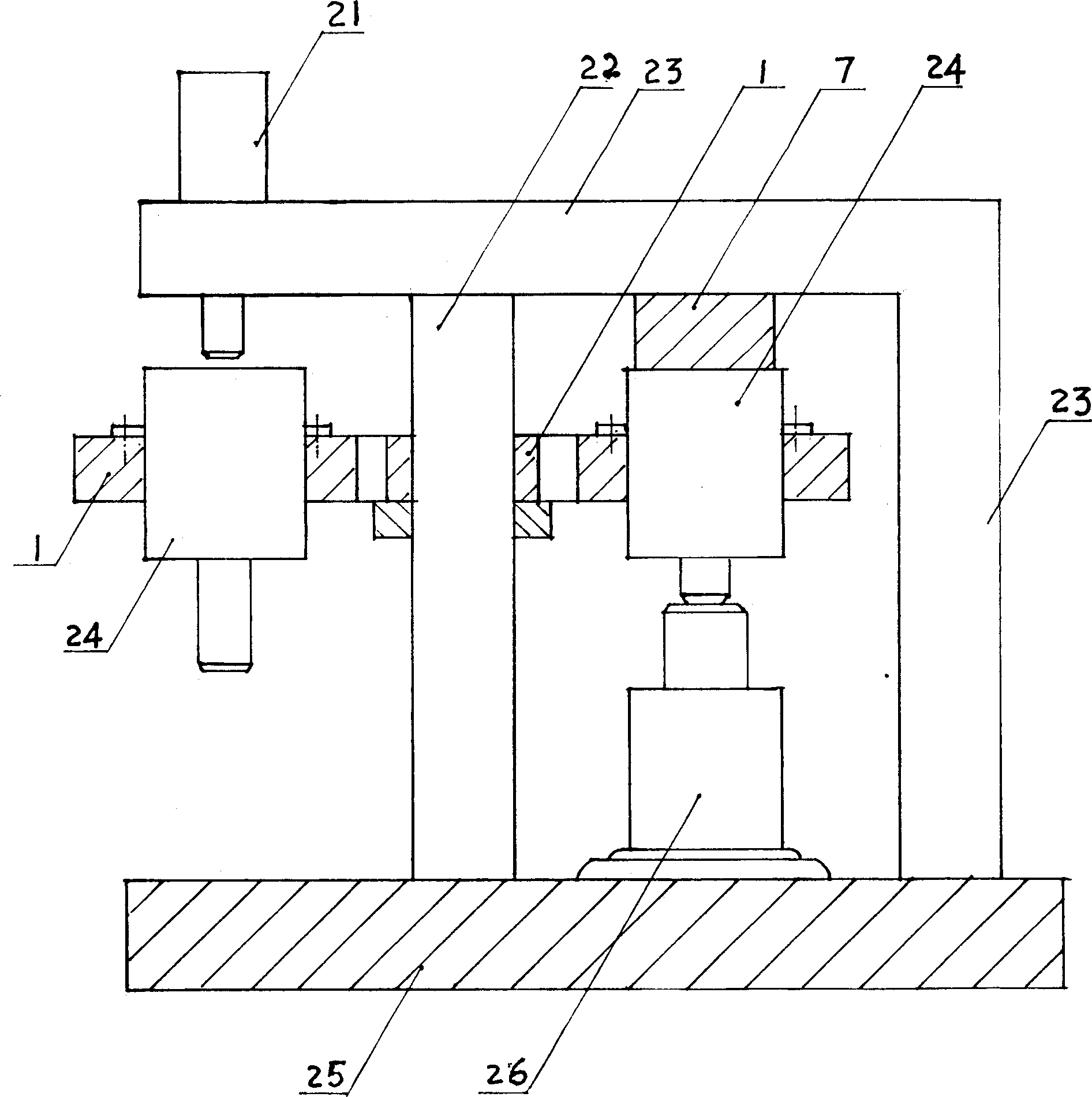

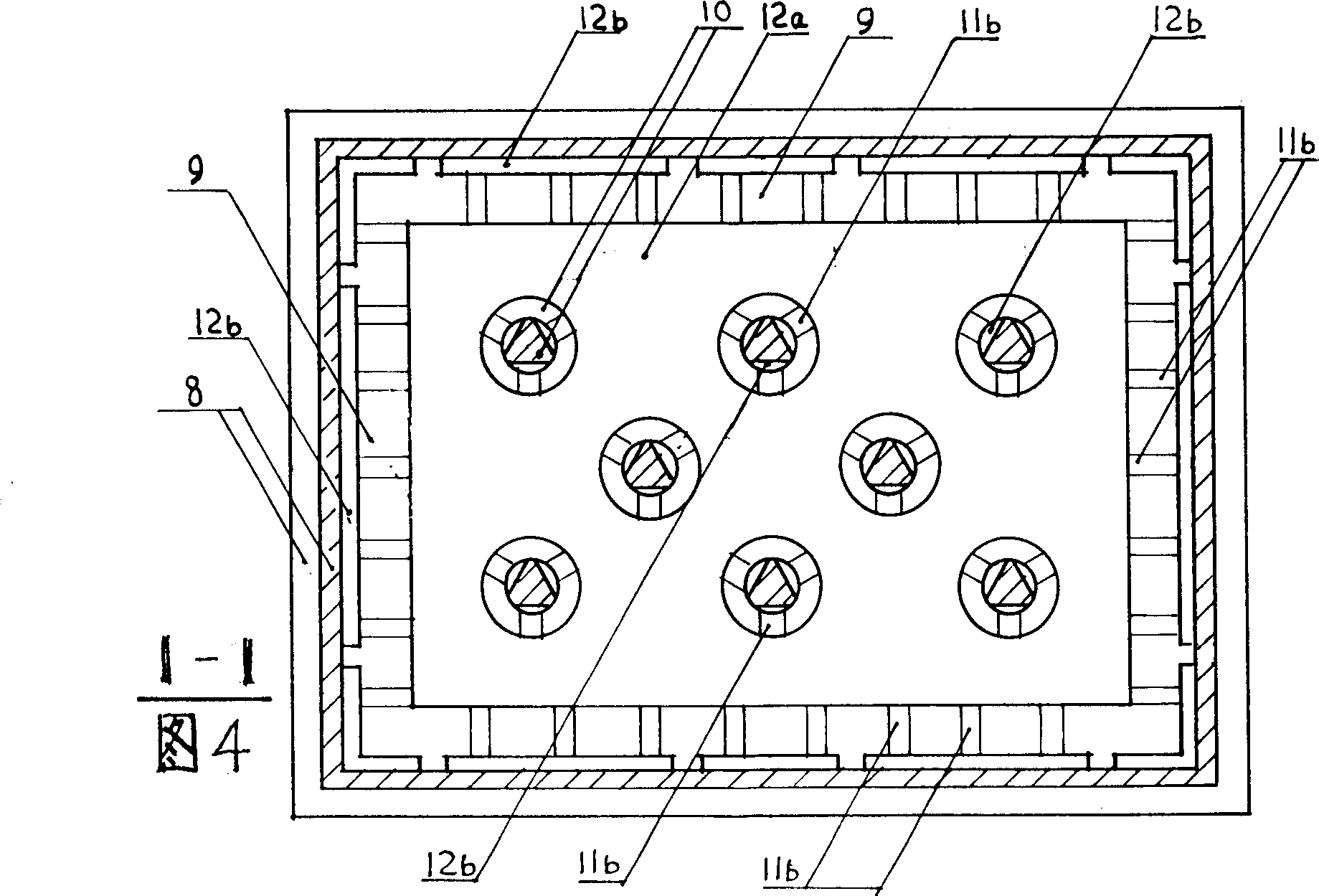

[0028] refer to figure 1 A dehydration device 24 is arranged symmetrically in the middle of a rotatable continuous circulation mechanism turntable 1, the turntable is mounted on the central axis 22 of the dehydration frame, and an upper cover 7 and a top press station are respectively provided above and below the turntable. Pressure oil cylinder 26, and the reset oil cylinder 21 of reset station.

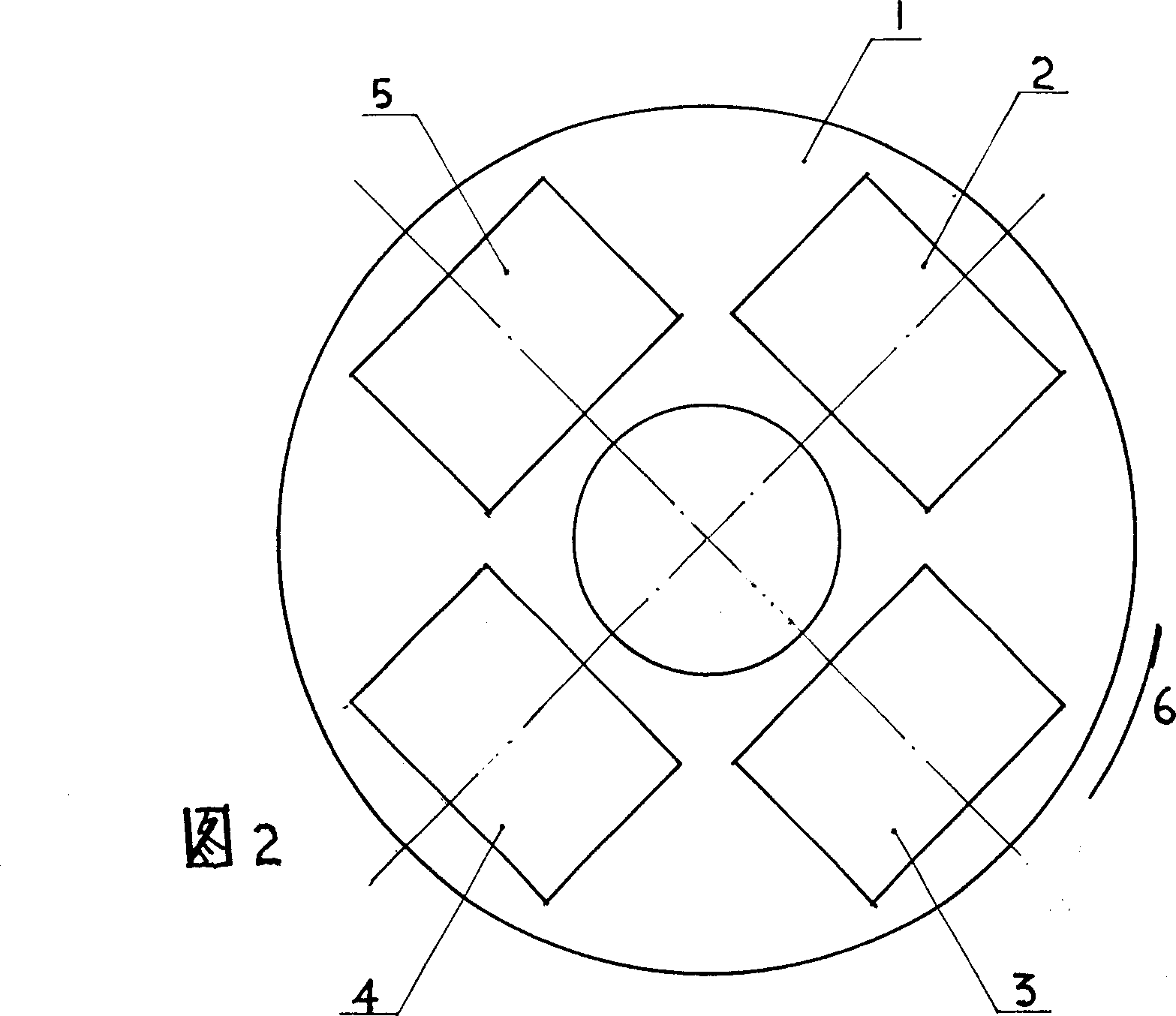

[0029] Referring to the continuous circulation mechanism shown in Figure 2 is a turntable driven by a motor. Corresponding to four stations on the turntable, four spaces are provided, and four dehydrating devices 24 can be installed in these four spaces. The four stations are made up of action actuators that are located above and below the turntable and are installed on the dehydration frame 23 and the dehydration machine base 25 respectively.

[0030] At the position 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com