Symmetric chromatic separated gratings

A color separation and symmetrical technology, applied in the field of color separation gratings, can solve the problems of misalignment of phase steps on the phase plate of alignment error, double frequency light residue, etc., and achieve the effect of solving the residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

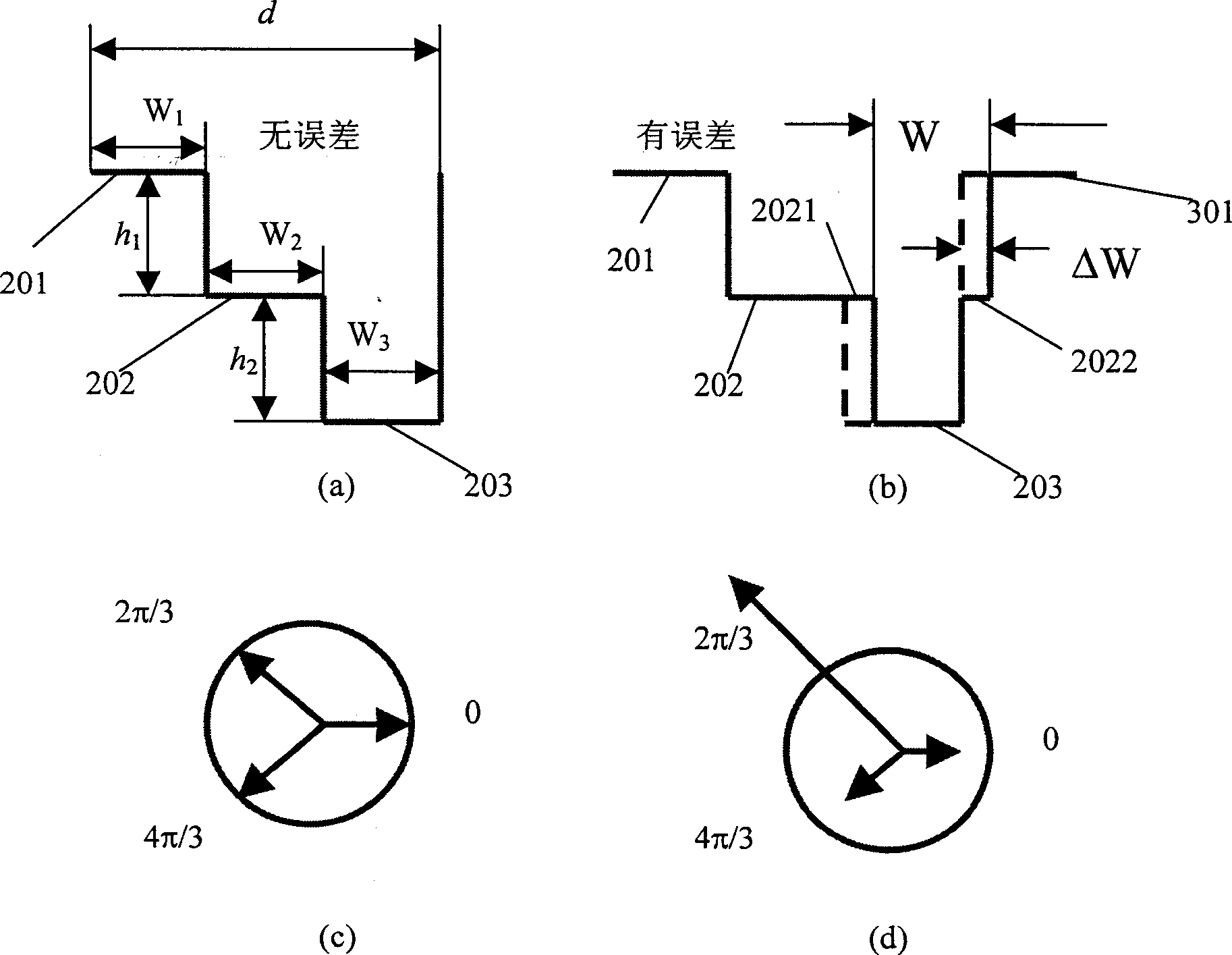

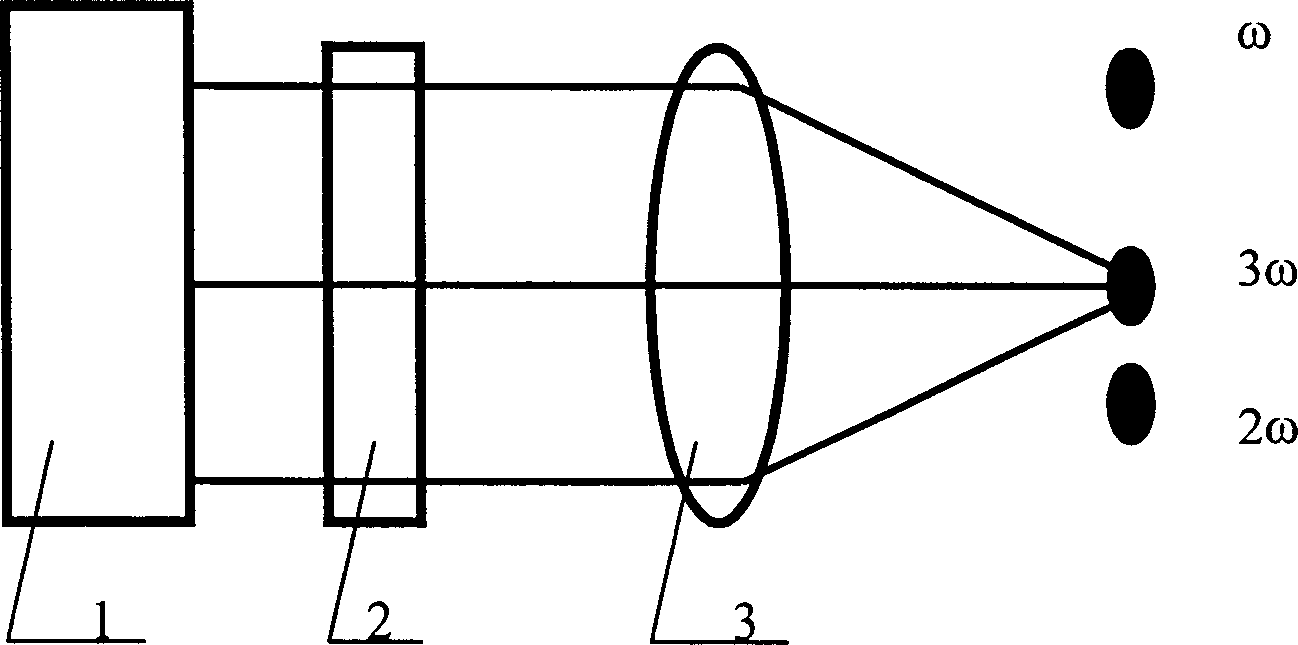

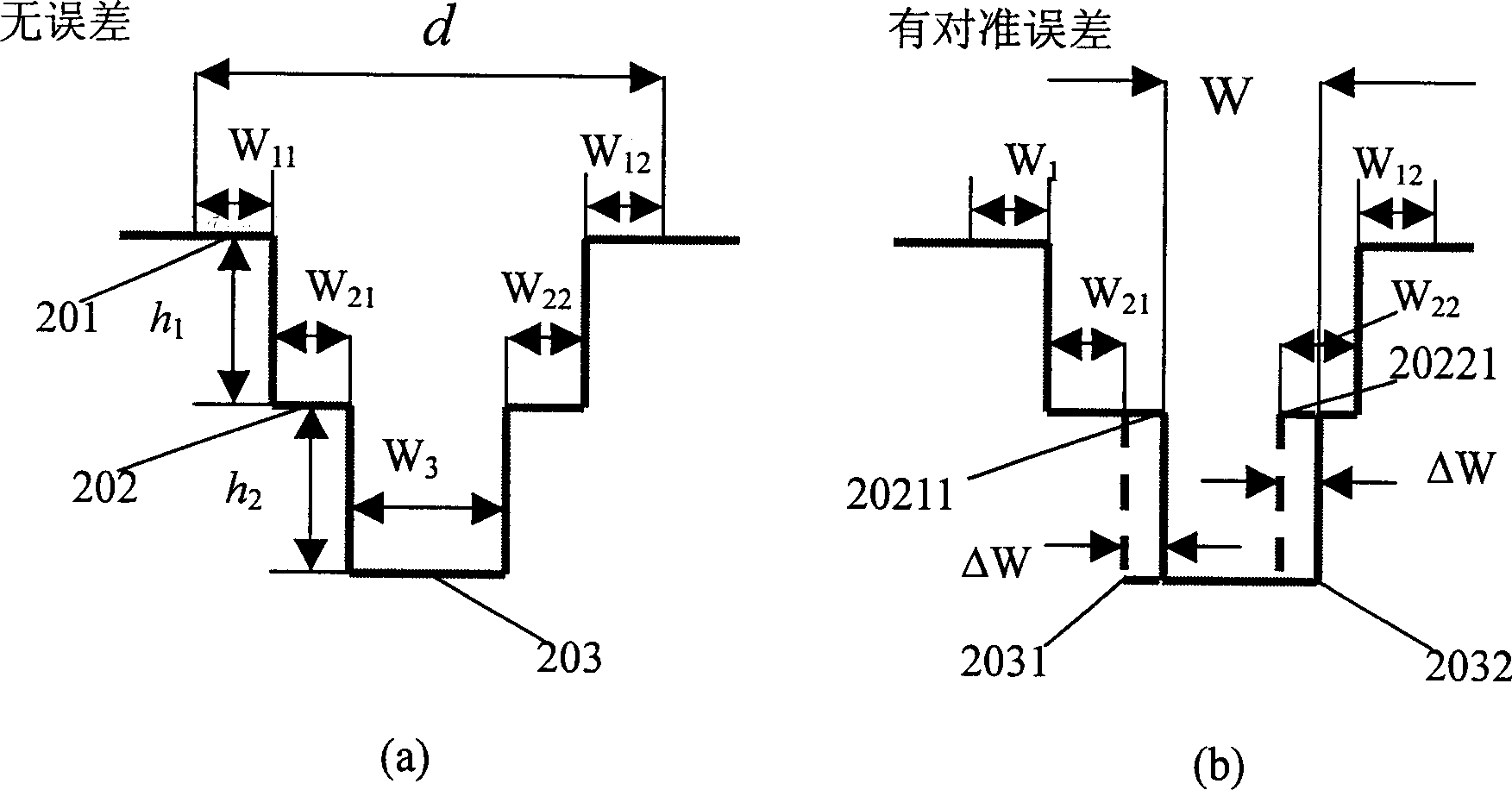

[0023] first please refer to image 3 and Figure 4 . The use of symmetrical color separation grating in the optical path is as follows: Figure 4 as shown, Figure 4 1, 3 functions of optical components and figure 2 It is exactly the same as in , here only the symmetrical color separation grating 2 is used, and its phase distribution is completely symmetrical. The parts from left to right are: W 11 , W 21 , W 3 , W 22 , W 12 ,like image 3 As shown in a, for fundamental frequency light, its phase distribution is: 0, 4π / 3, 8π / 3, 4π / 3, 0, for double frequency light, its phase distribution is: 0, 2π / 3, 4π / 3, 2π / 3, 0, therefore, after the fundamental frequency light and the double frequency light pass through such a symmetrical color separation grating, they will be symmetrically distributed on both sides of the focal point of the converging lens, such as Figure 4 shown. For the frequency tripled light, the depth of each stepped phase is an integral multiple of 0 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com