Non-contact cards producing method and non-contact cards thereby

A production method and a contactless card technology, applied in the field of smart cards, can solve the problems of high cost and low production efficiency, achieve the effects of reduced manufacturing cost, simple and convenient manufacturing process, and suitable for mass production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with specific embodiments.

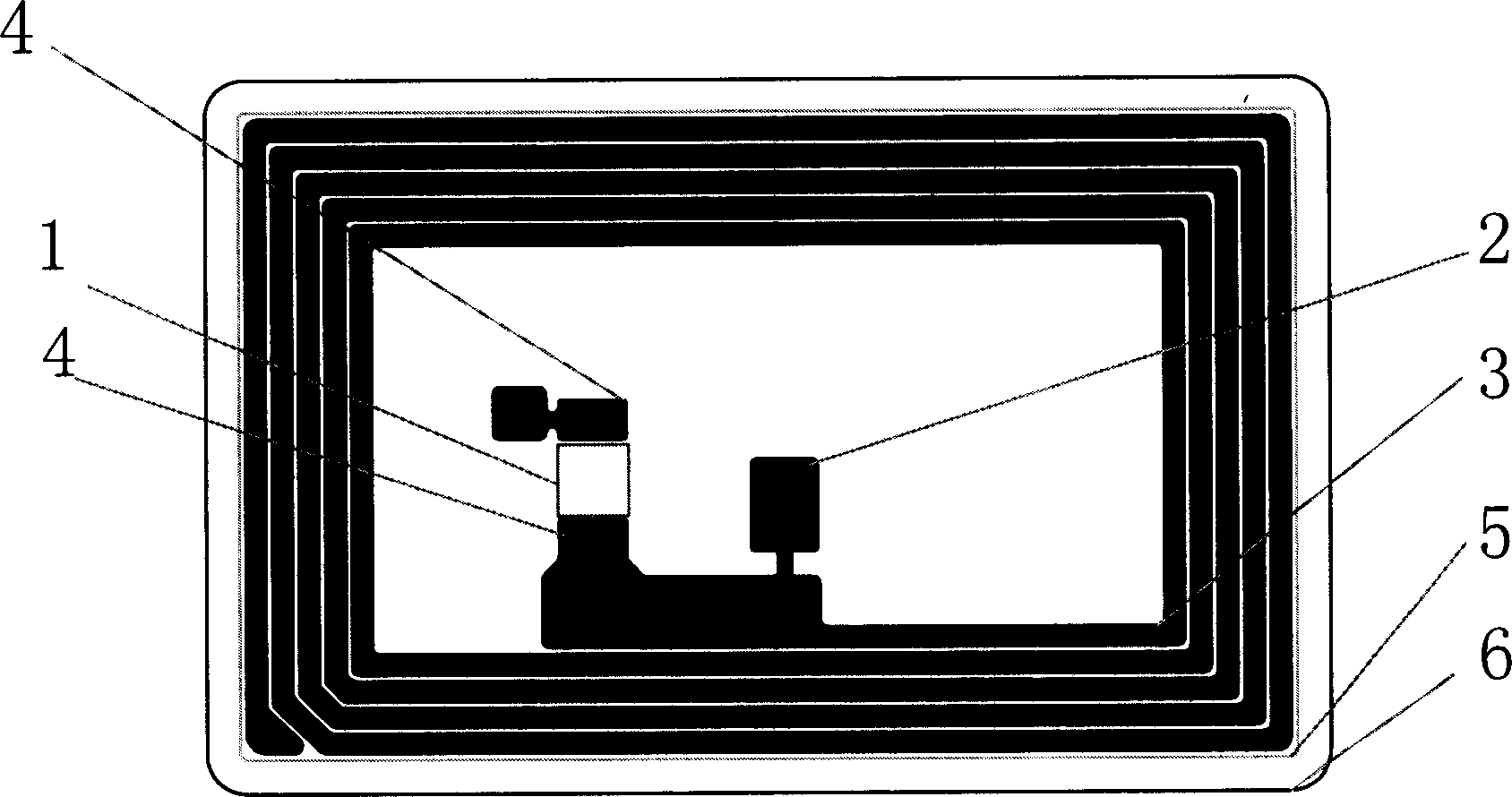

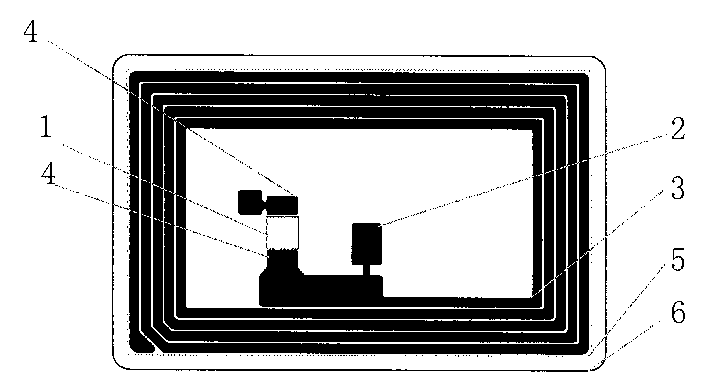

[0010] Such as figure 1 , the contactless card involved in the present invention comprises radio frequency module 1, module welding pad 4, polyester film 5, PVC card base 6, also comprises the coil 3 and film capacitor 2 that are made by corrosion method, coil and film capacitor and radio frequency The modules are electrically connected to the mylar.

[0011] The method involved in the present invention makes contactless card,

[0012] The first step in the process is module encapsulation.

[0013] First, thin the disk chip to 0.15-0.18mm, and then cut it; use a machine to combine the cut chip with silver paste and strips, and reach the tangential thrust standard> 500g / mm 2 ; For the finished semi-finished product to be soldered with gold wire, use gold wire to connect the solder joints and strips of the chip to form a path, and test to meet the following standards: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com