Method for igniting rotary motor without carbonbrush for driving IC engine

A technology of rotating electric machines and starting methods, which is applied to the starting of engines, the starting of motors for engines, machines/engines, etc., and can solve problems such as inability to switch to power on, accuracy rate of only 1/3, and inability to detect rotor position induced voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

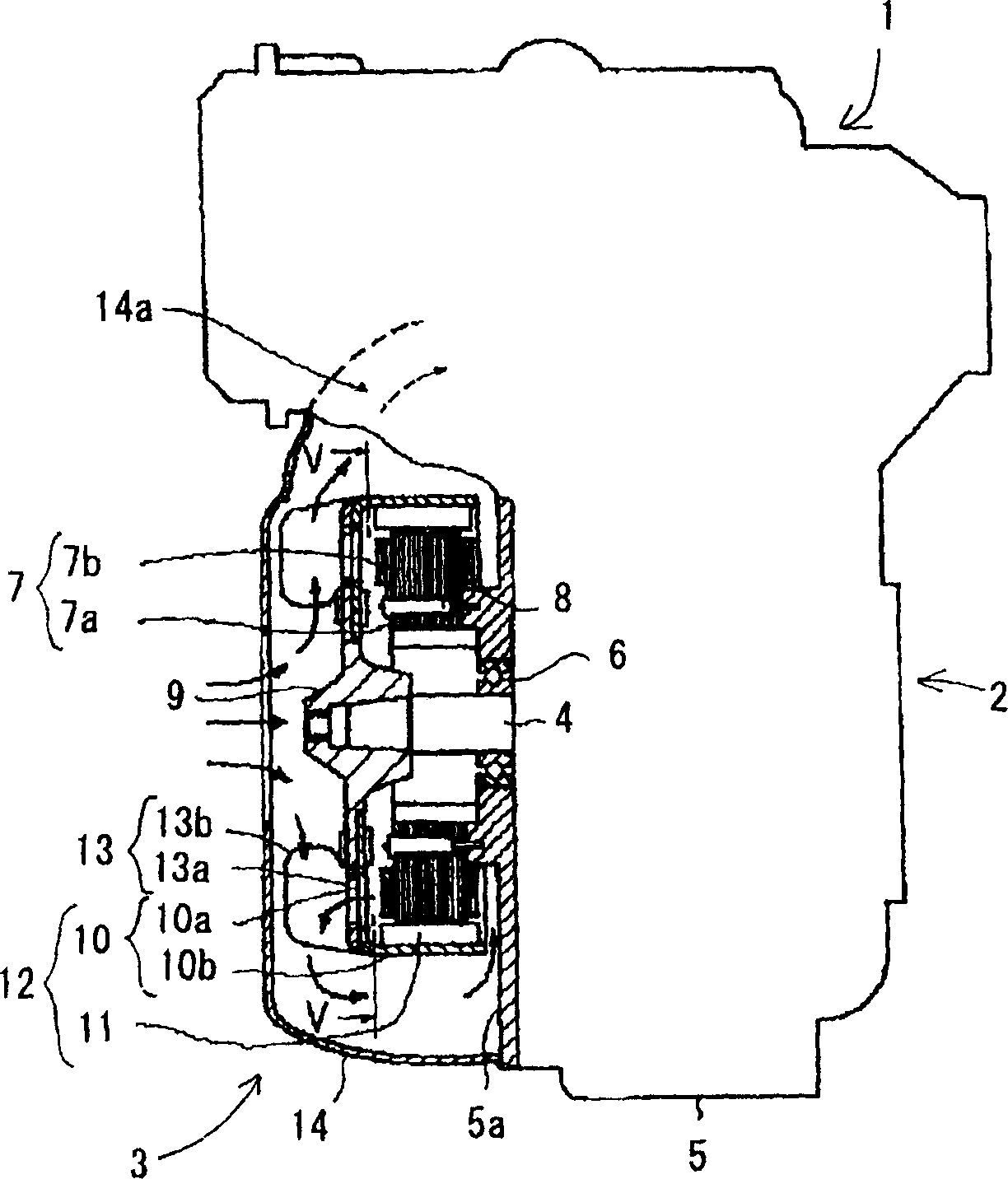

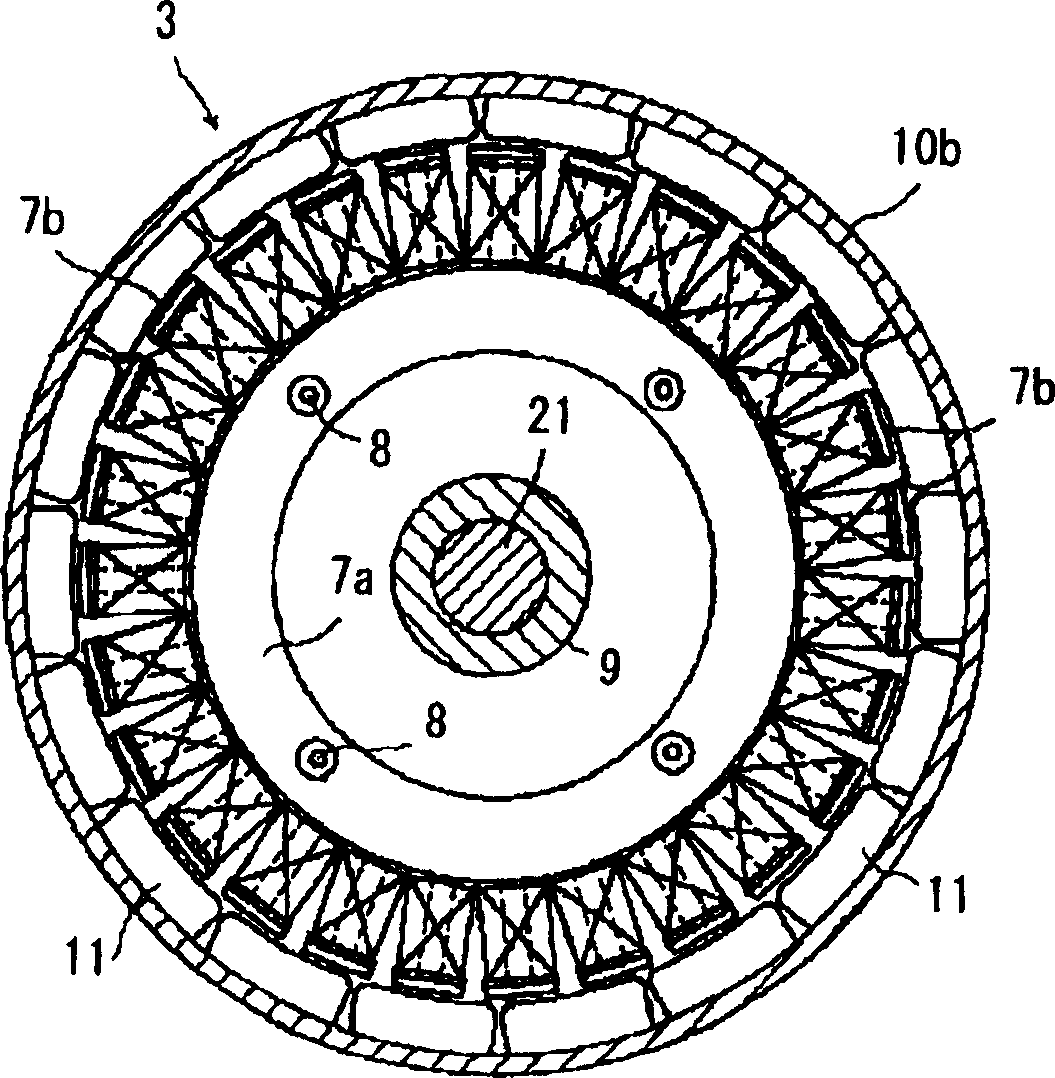

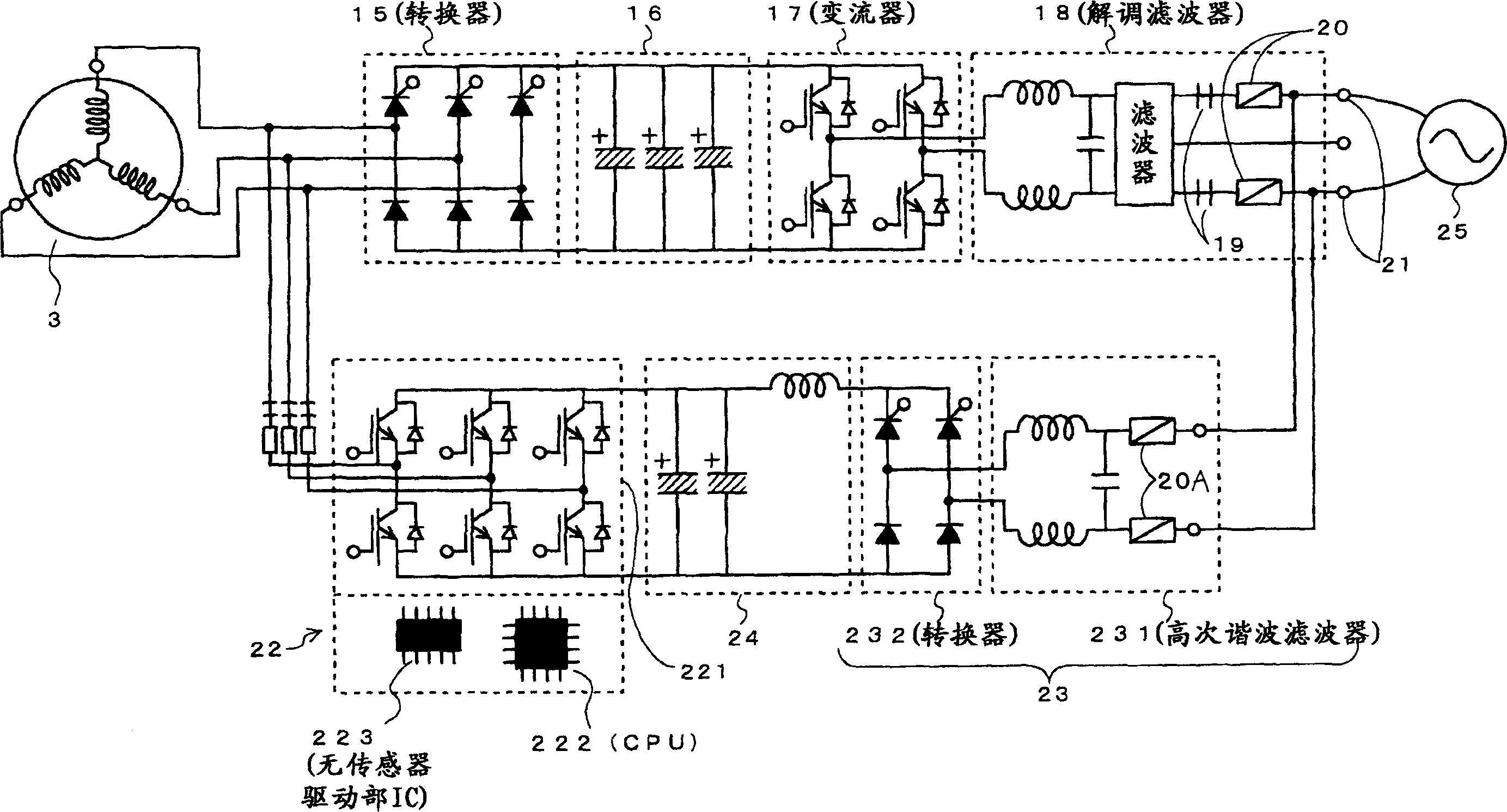

[0039] An embodiment of the present invention will be described in detail below with reference to the drawings. figure 1 is a side view of an engine power generator as an example of a brushless rotating electric machine, figure 2 yes figure 1 Sectional view of V-V.

[0040] The engine generator 1 has an engine 2 and a generator 3 . The generator 3 is a magnet type multi-pole generator. A crankshaft 4 of the engine 2 is supported by a bearing 6 provided on a side wall 5 a of the crankcase 5 . One end is drawn out to the outside of the engine 2 . On the peripheral boss of the side wall 5 a of the crankcase 5 surrounding the crankshaft 4 , an annular star core 7 is fixed by bolts 8 . The iron core 7 is composed of an annular yoke portion 7 a and 27 display electrode portions 7 b protruding radially therefrom.

[0041] Three-phase coils are alternately wound sequentially on the display pole portion 7 a to form the stator 8 . Such multi-polarization of the core 7 achieves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com