Multimode optical fiber row and prism coupled double wrapping optical fiber device and its coupling method

A double-clad fiber and fiber coupler technology, applied in the field of lasers, can solve the problems of difficult realization, complex process and high technical requirements, and achieve the effect of easy simultaneous multi-point pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

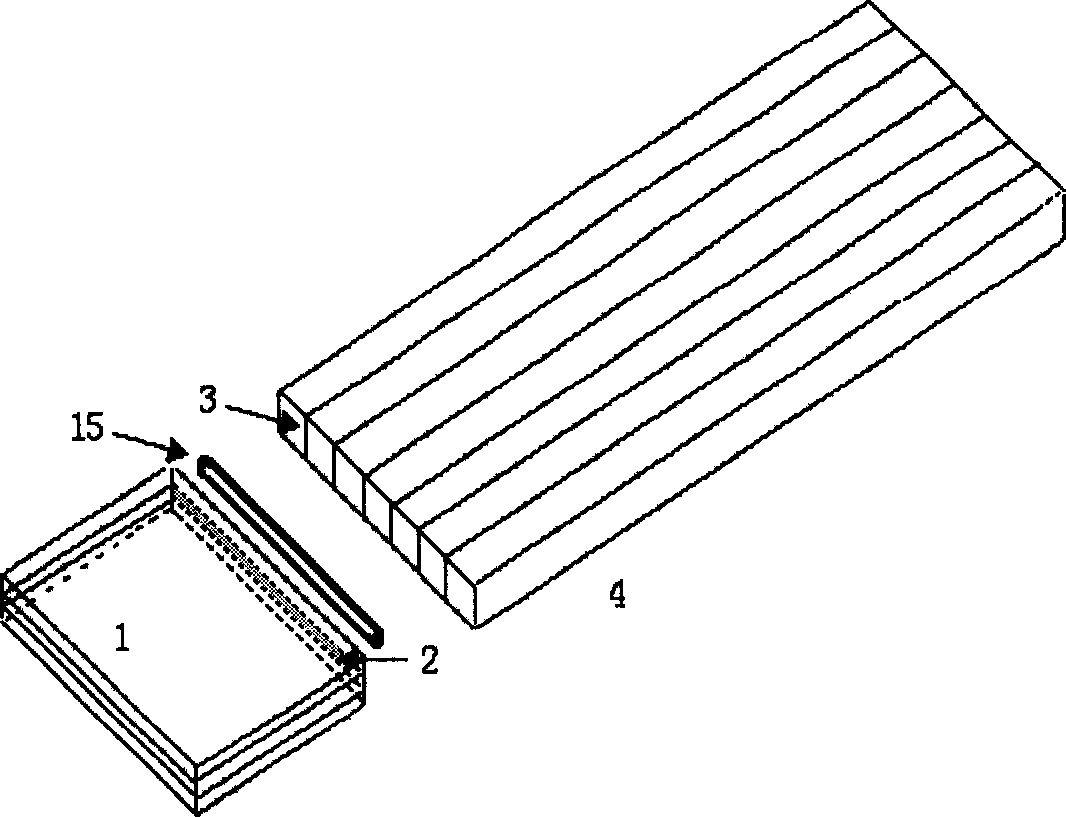

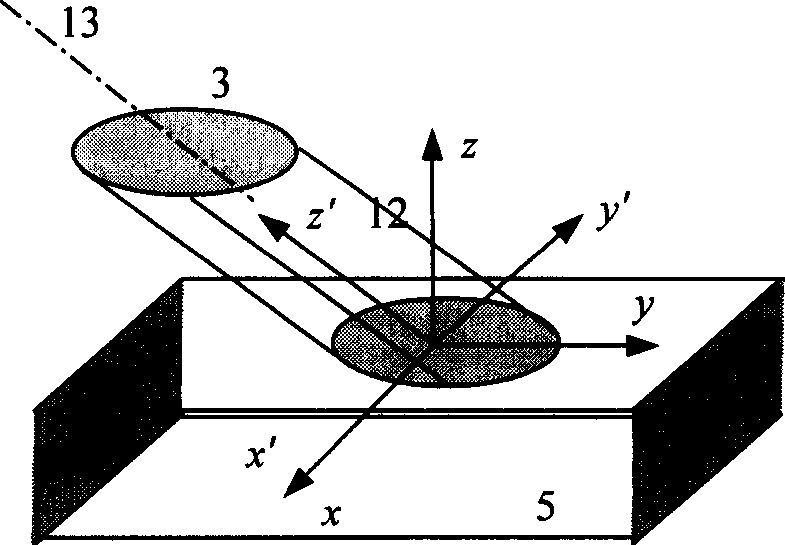

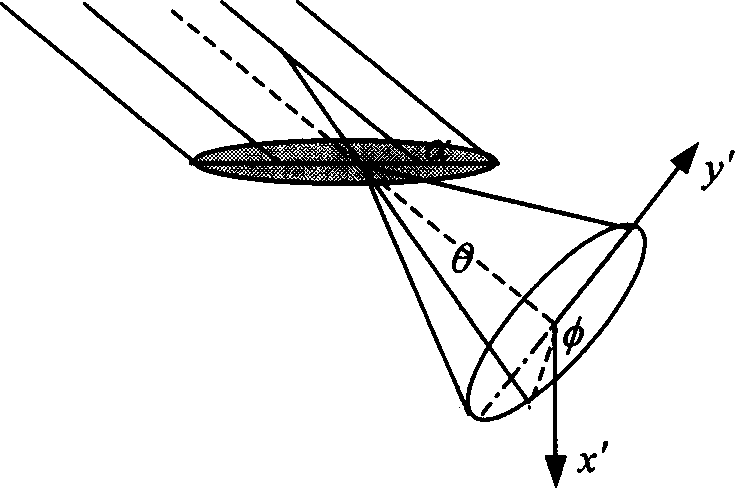

[0018] Multimode fiber row mode: figure 1 It is a schematic diagram of the optical path of the multimode fiber row coupling mode. The width of the multimode fiber row 4 is slightly larger than the width of the strip pump light output by the semiconductor laser array. The strip-shaped pumping light output by the semiconductor laser array is converged by the micro-cylindrical lens 15 and then injected into the multimode fiber row 4. After the pumping light is introduced into the multimode fiber, the multimode fibers can be scattered or concentrated into a fiber bundle or a fiber row . The light-emitting surface of the multimode fiber is ground and forms an angle α with the axis. The angle is determined according to the refractive index of the inner cladding 5 material of the double-clad fiber, so that the pump light is emitted from the light-emitting surface of the multimode fiber and then passes through the multimode fiber. The light-emitting surface and the optical contact s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com