Device and method for manufacturing soft metal tube

A manufacturing method and a manufacturing device technology, which are applied in the field of metal flexible pipe manufacturing and manufacturing devices, can solve problems such as difficult unwinding of copper pipes, and achieve the effects of saving space and reducing costs for the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

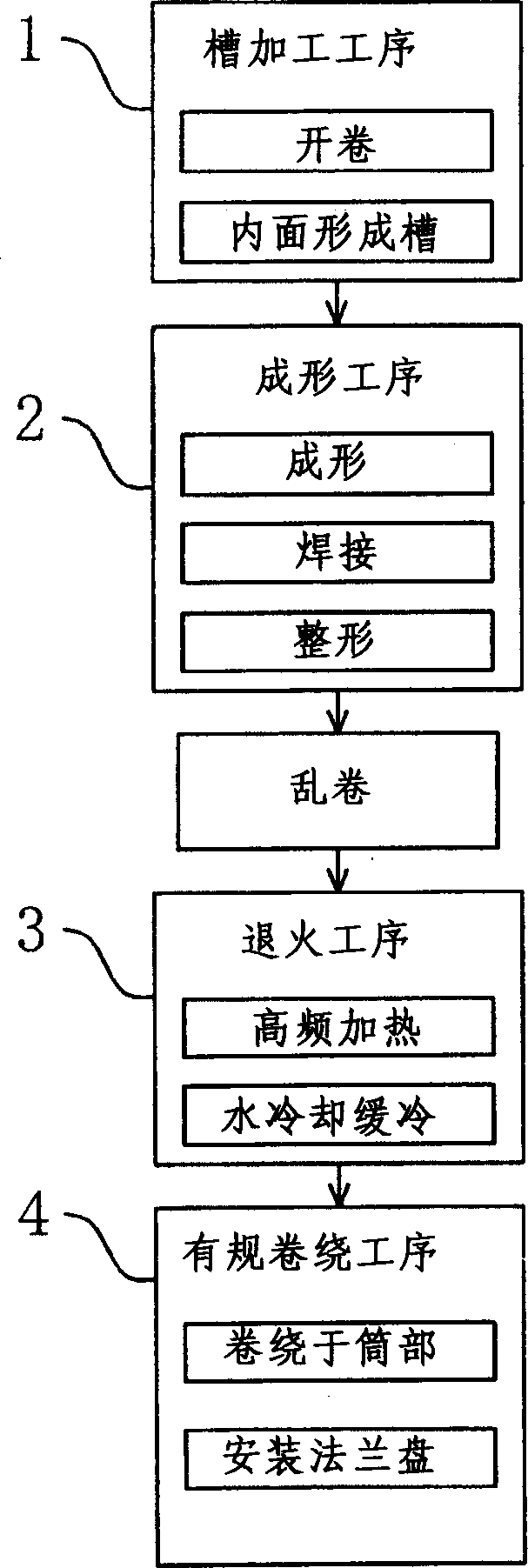

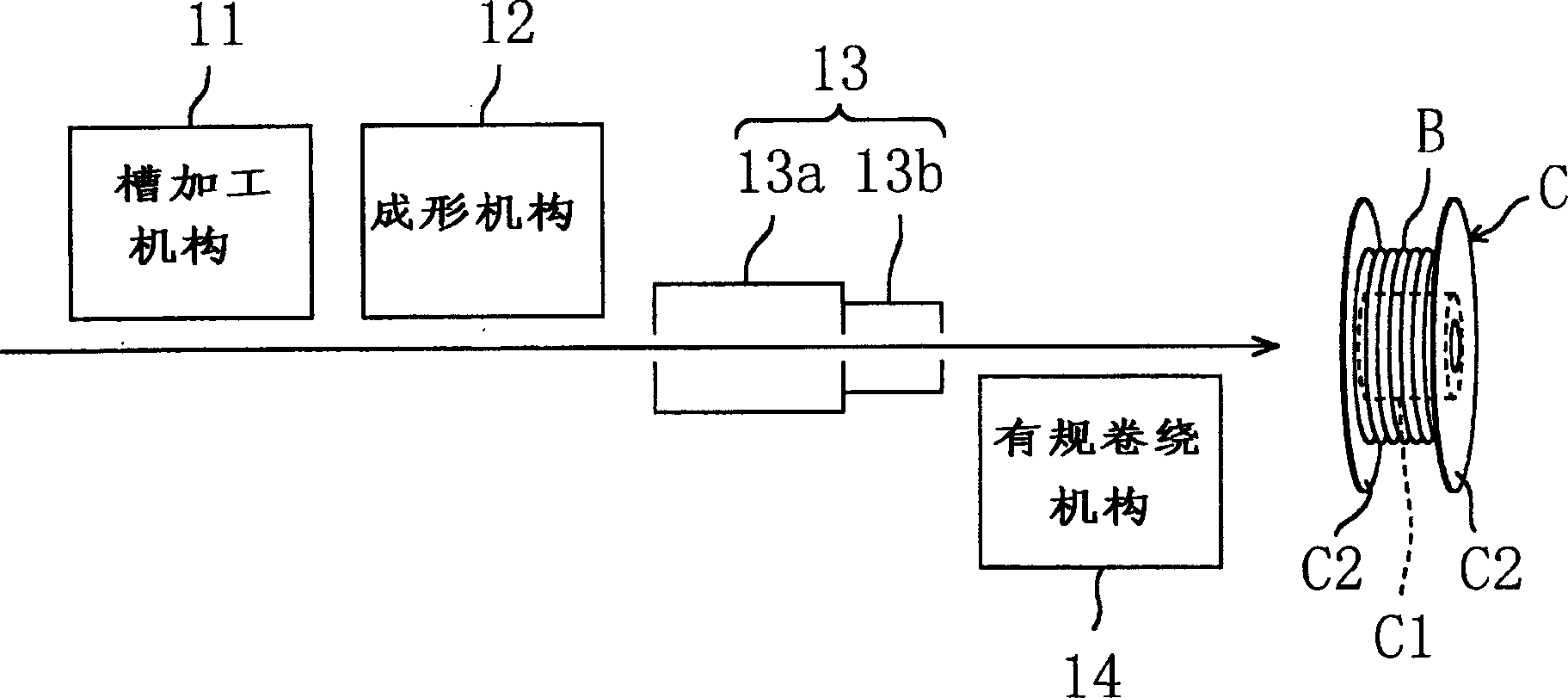

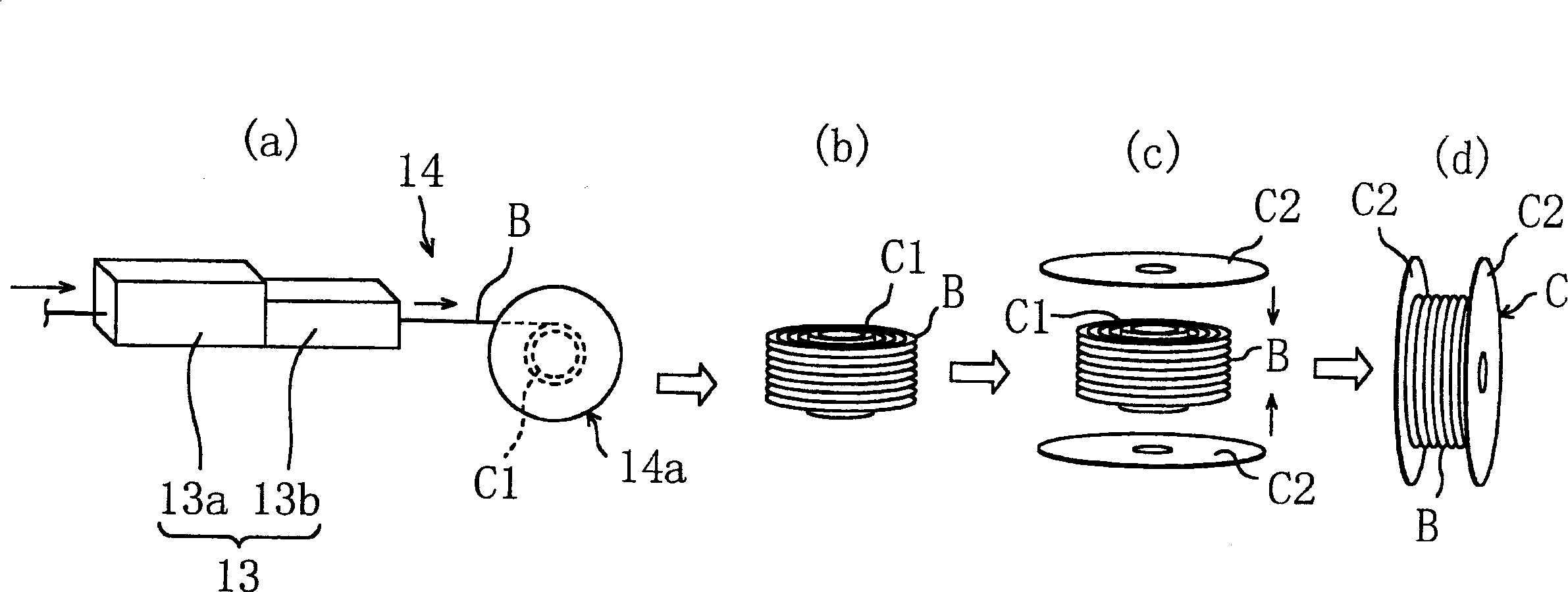

[0049] figure 2 It is a schematic diagram showing the overall configuration of a heat transfer tube manufacturing apparatus according to an embodiment of the present invention.

[0050] This device is a device assembled to a heat exchanger with a strip-shaped long soft copper plate (described in the conventional technical item) with a thickness of about 0.5 mm and a width of about 30 mm. The above-mentioned manufacturing apparatus is used for manufacturing a heat transfer tube (B) having a diameter of several mm (for example, 7 mm to 8 mm) with internal grooves.

[0051] The aforementioned manufacturing device, as a basic structure, includes: a groove machining mechanism (11) that forms a plurality of grooves on the soft copper plate by rolling; the copper plate that is grooved by the groove machining mechanism (11) is formed into a heat transfer The forming mechanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com