End semiconductor pumping bidirectional solid ring laser

An end-pumped, bidirectional solid-state technology, applied in lasers, laser components, phonon exciters, etc., can solve the problems of low efficiency and reliability, achieve low energy loss, overcome high coating requirements, overcome temperature drift and Non-Linear Insufficient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

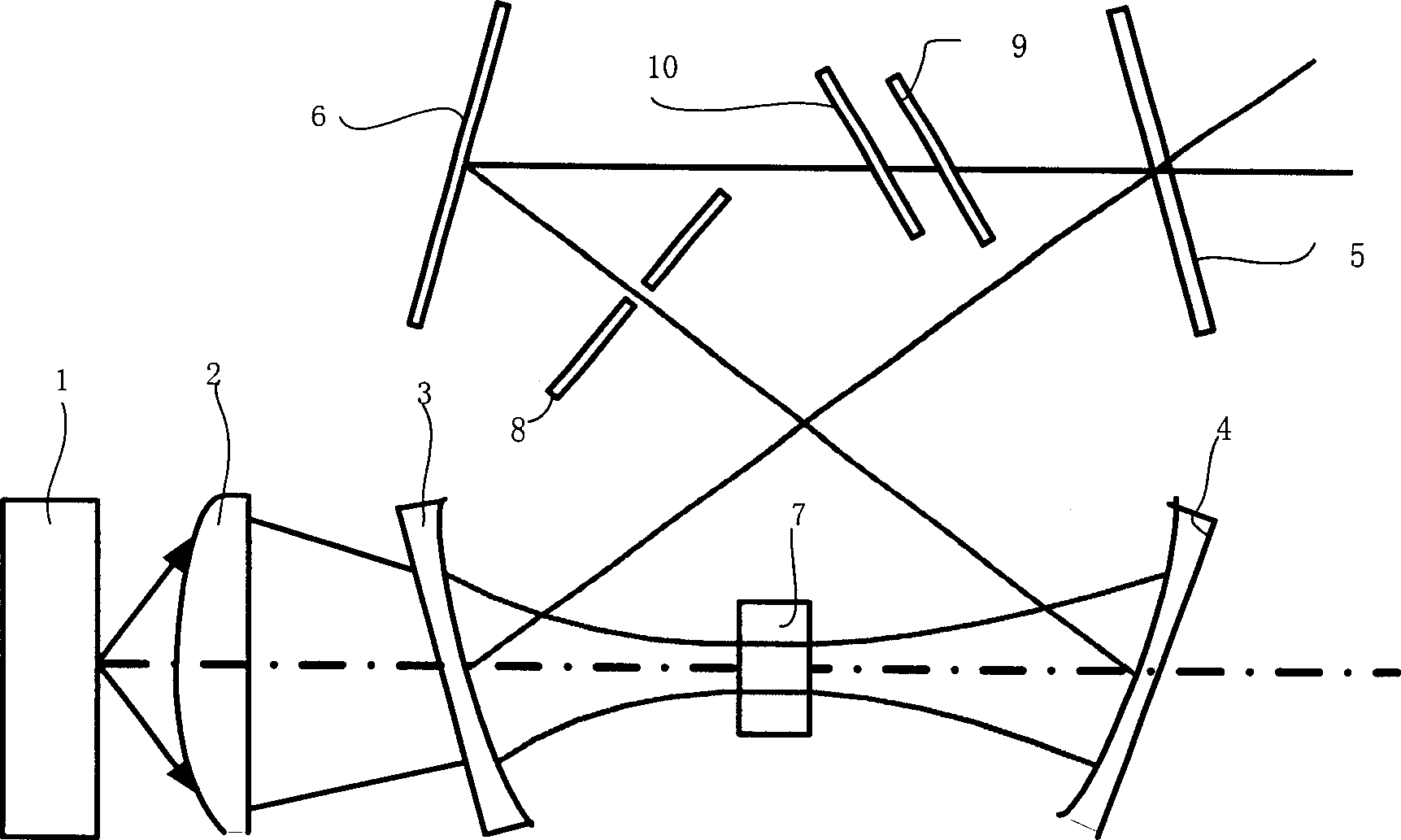

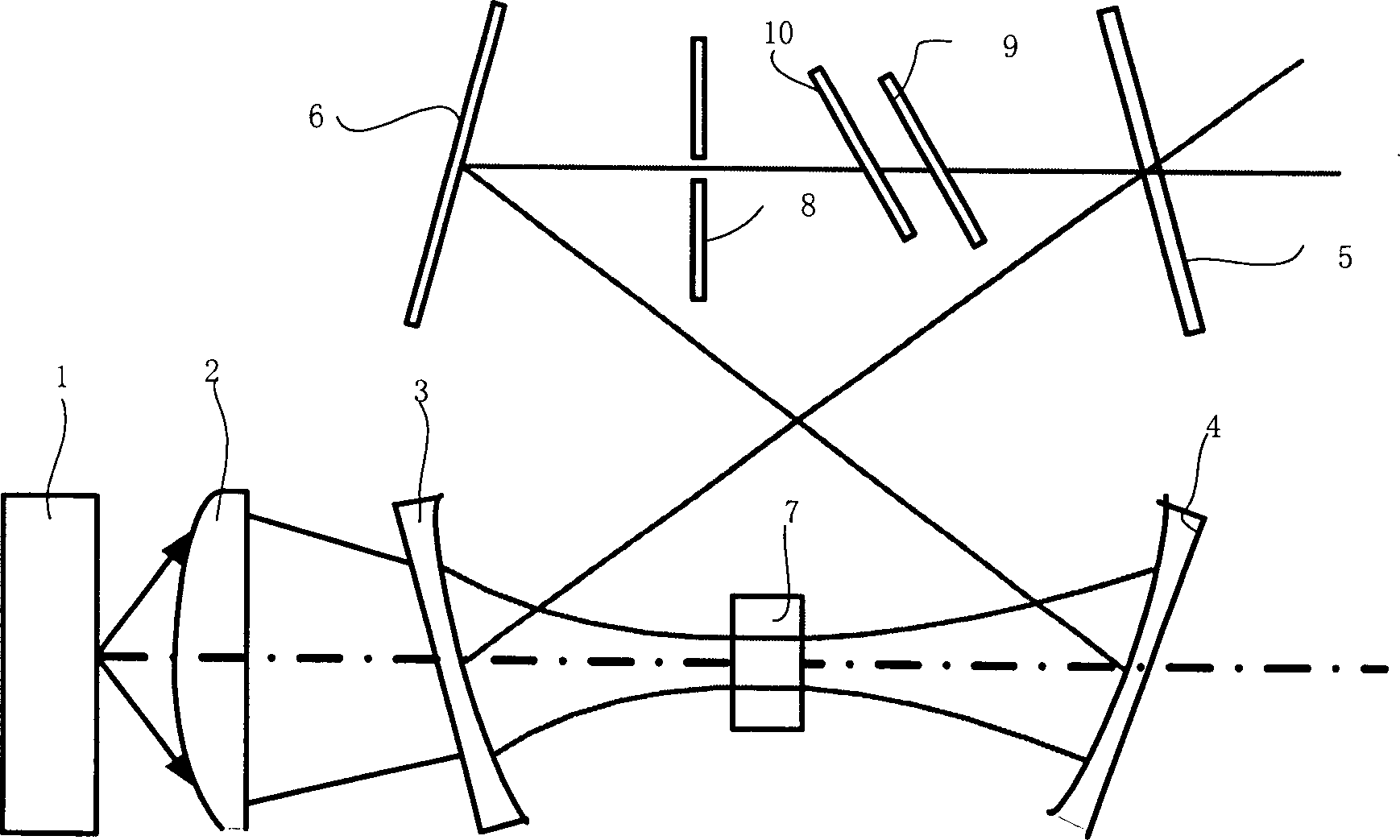

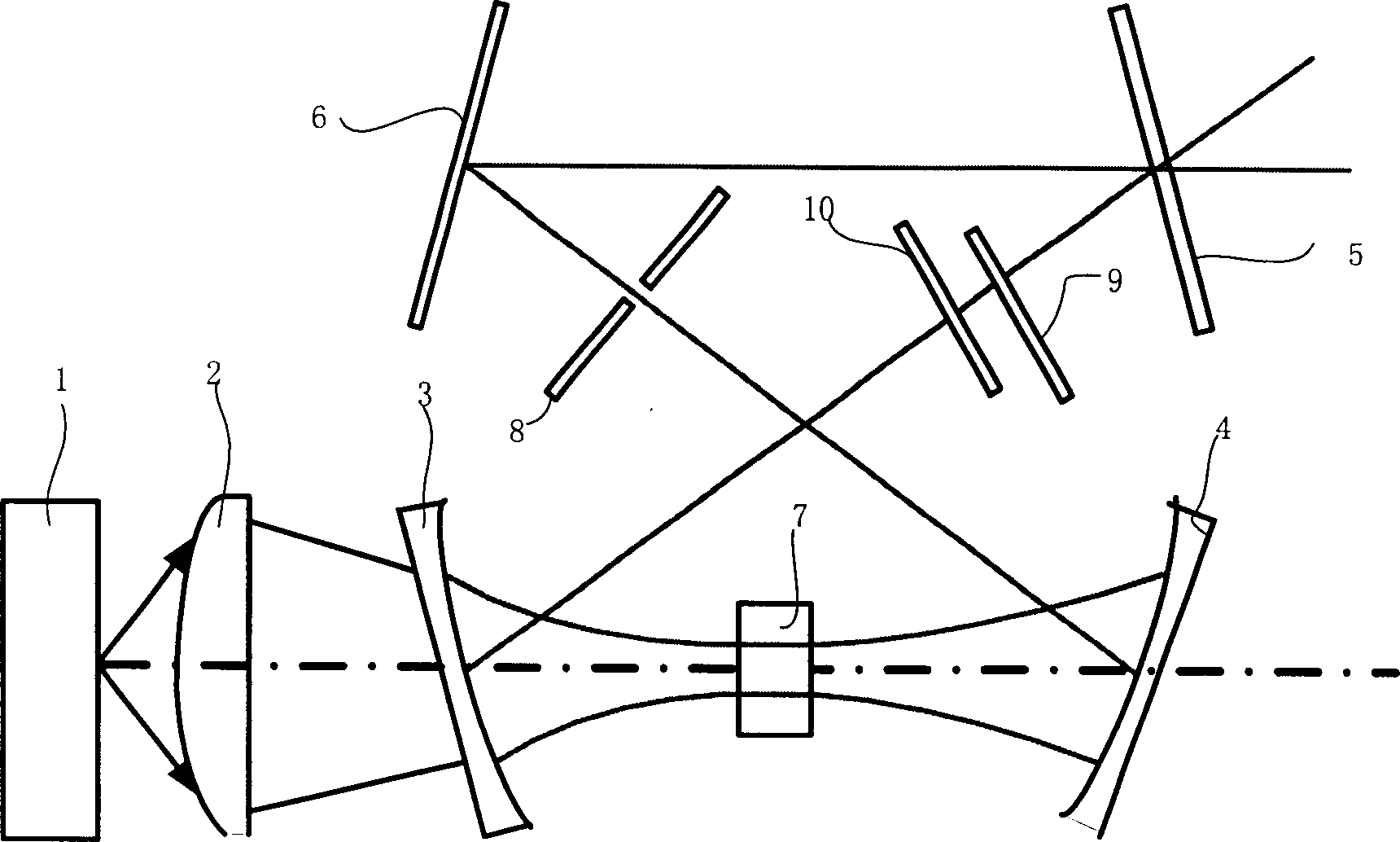

[0021] Embodiment: the structural representation of this system is as figure 1 shown. The detailed steps are as follows: the semiconductor laser array 1 used is a 6W GaAlAs / GaAs double heterojunction laser array with a peak wavelength of 810±5nm, which is fixed on a semiconductor refrigerator and controlled by a temperature control system. The gain medium 7 adopts a crystal whose absorption wavelength matches the peak wavelength of the semiconductor laser. We choose a very mature Nd:YVO 4 , did not choose Nd: YAG. Nd: YVO 4 The doping concentration of the crystal is ≈0.5%, the geometric shape is a slab, the size is 10×5×5mm, the input and output end faces (that is, two 5×5mm faces) are plated with a high-transparency film with a reflectivity of less than 0.1% for the 1064nm wavelength, and the crystal is used The indium foil wrap (for good thermal contact) is placed inside the copper block, which is cooled and temperature controlled by a peltier cooler. The annular cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com