Selective colour forming glasses lens by light absorbing material and control method thereof

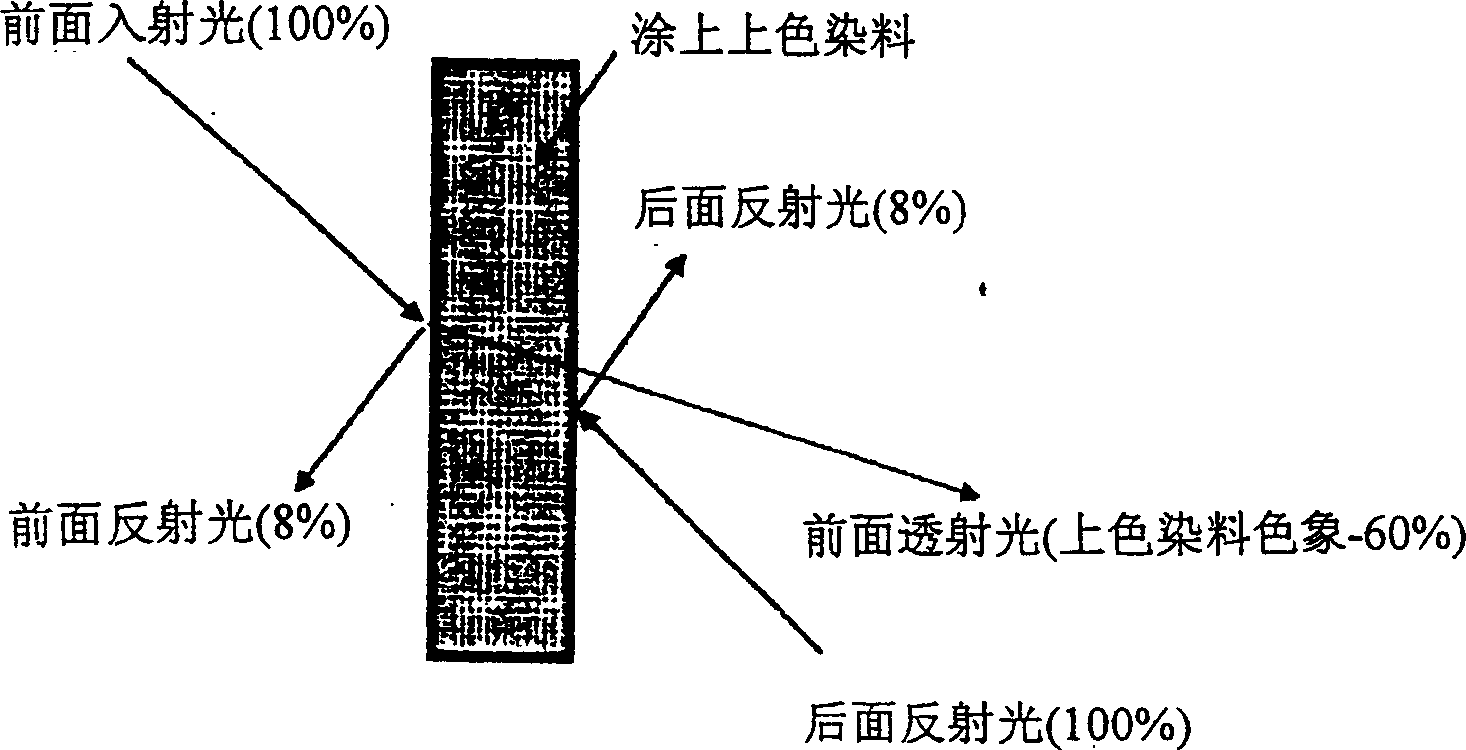

An ophthalmic lens, selective technology, applied in the field of controlling low reflection and transmission color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

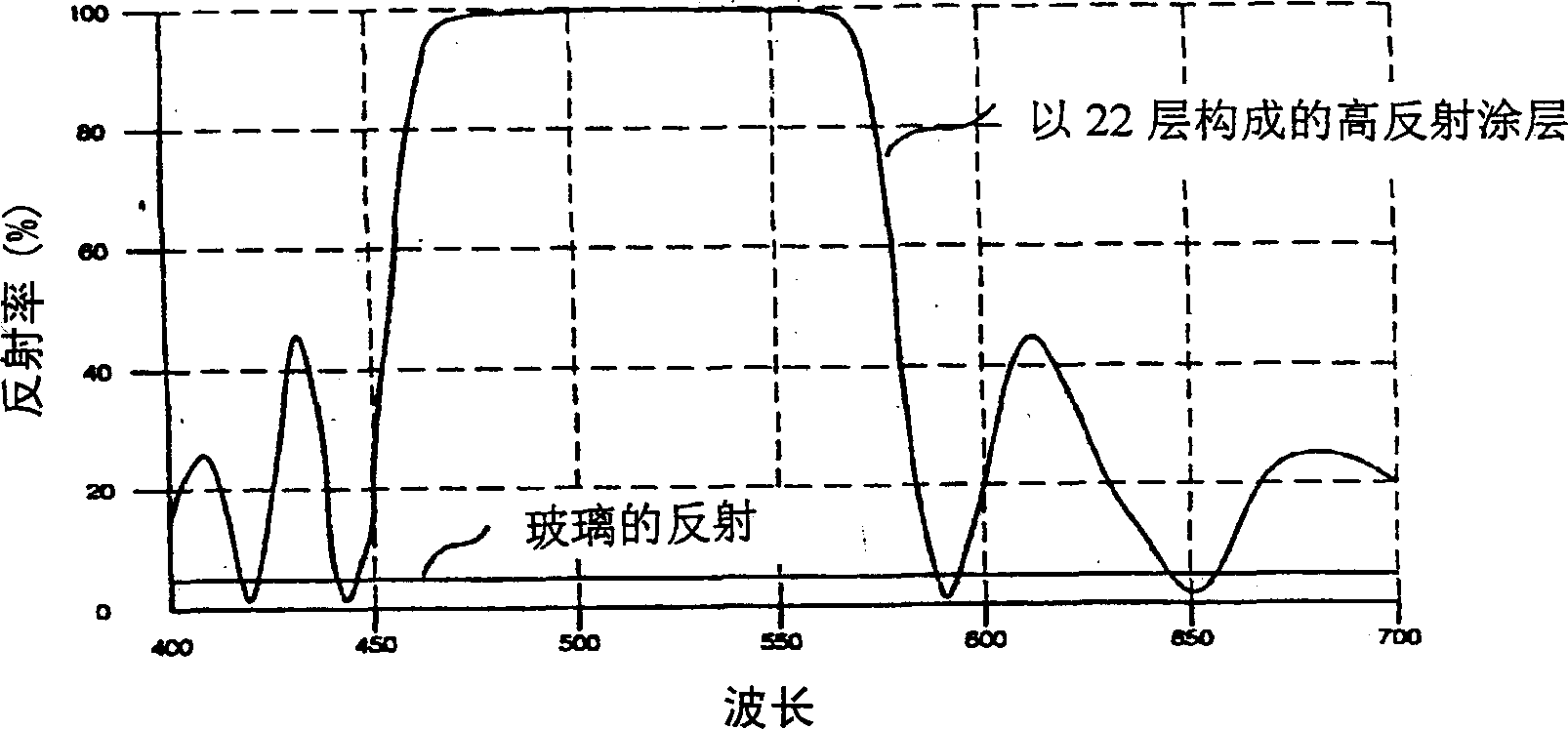

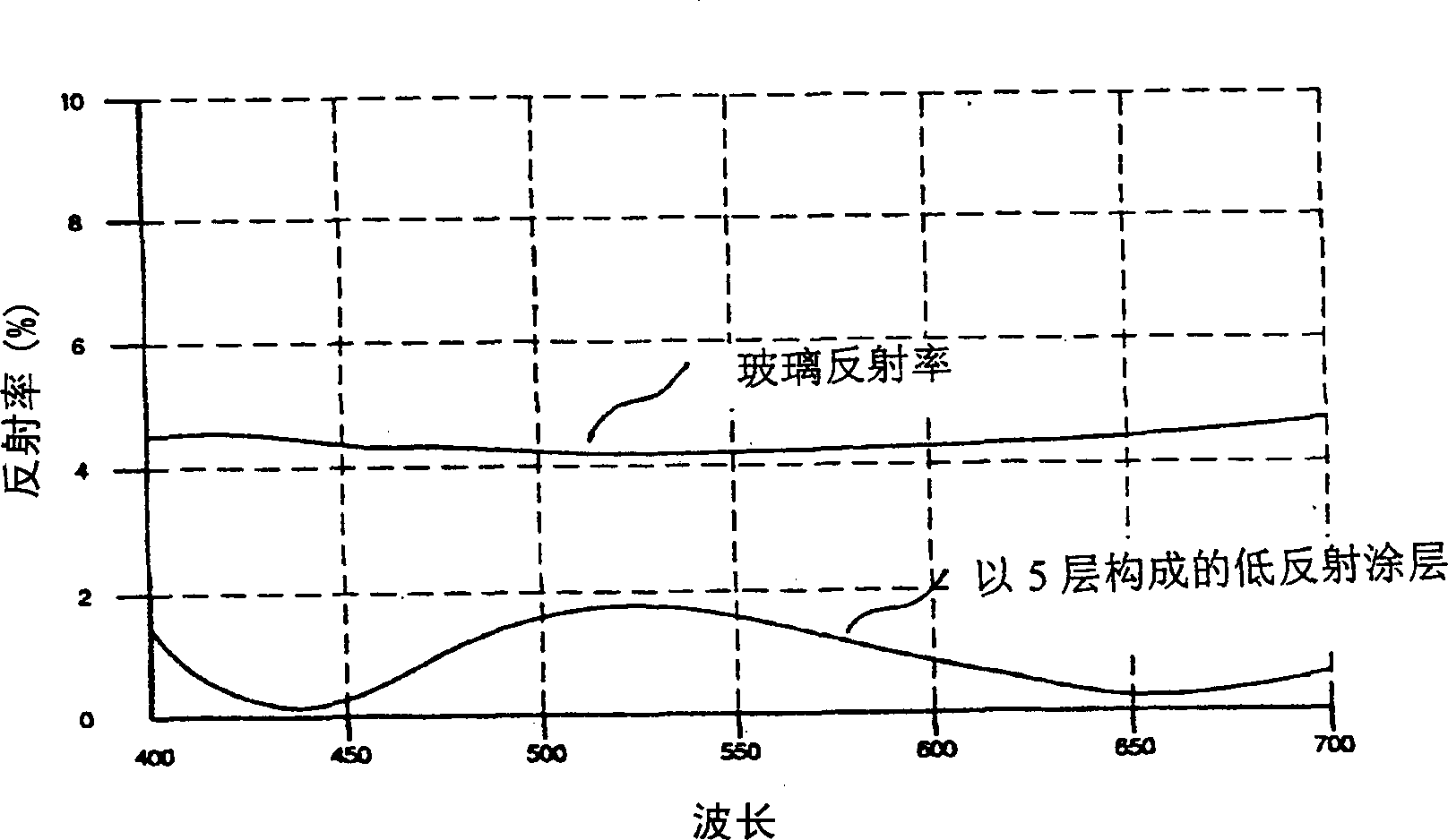

Embodiment 1

[0050] On the convex surface of the high refraction plastic lens with a refractive index of 1.61, a silicon dioxide series hard film with a thickness of 2 μm and a refractive index of 1.62 is coated by coating, and the above-mentioned lens substrate is placed in a vacuum chamber and decompressed with a vacuum pump. 3.0×10 -5 Torr. Then, accelerate the electron beam to carry out the paste work, and in order to improve the uniformity and physical properties of the film, ionize the oxygen gas, and irradiate the ionization energy to the substrate to carry out the paste. In this way, 1.46 low refractive index dielectric SiO is pasted on the front and back of the lens 2 and 2.06 high refractive index dielectric ZrO 2 . The order and thickness are shown in Table 2 and Table 3.

[0051] Material

SiO 2

ZrO 2

SiO 2

In 2 o 3

ZrO 2

SiO 2

Thickness

0.038

lambda 0

0.065

lambda 0

0.045

lambda 0

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com