Making process of gingko leaf cigarette with mellow taste

A processing method and technology of ginkgo biloba, which is applied in the field of processing the positive taste of ginkgo leaf cigarettes, can solve problems such as miscellaneous taste, peculiar smell, and influence on burning and smoking effects, and achieve the effects of improving physical properties, perfect smoking quality, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

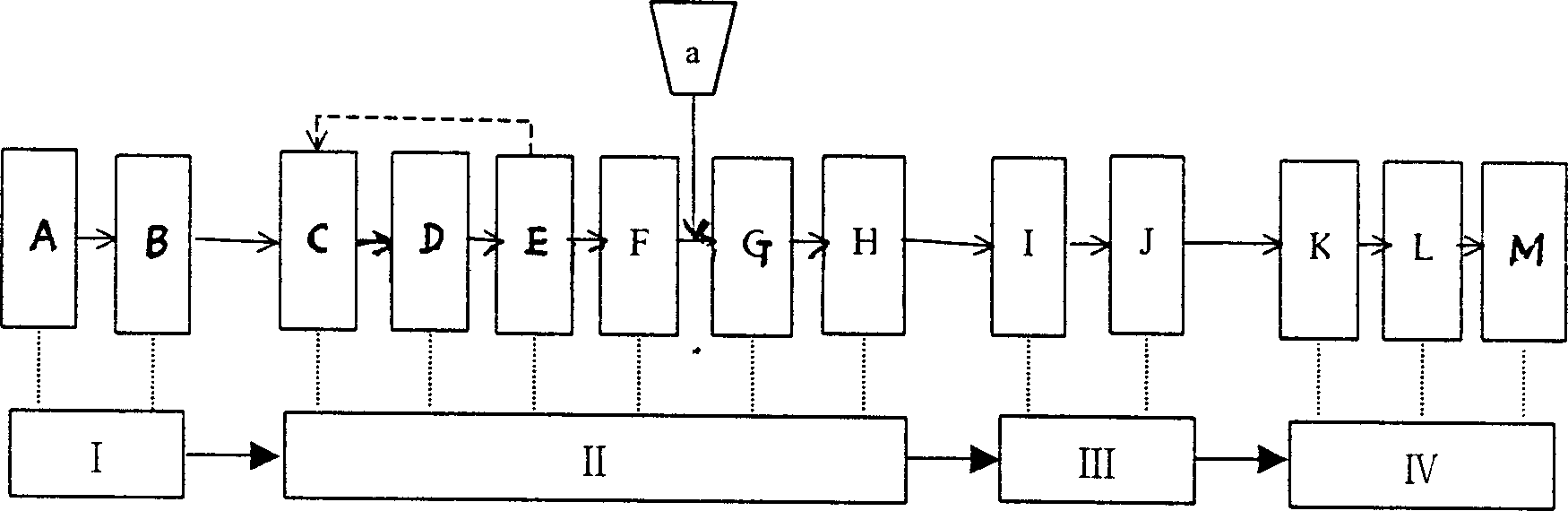

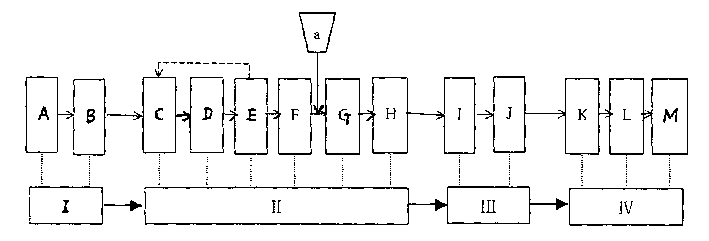

Method used

Image

Examples

Embodiment 1

[0017] After removing impurities, cleaning and sorting the purchased 100kg dried green leaves of ginkgo, artificially ferment them at a temperature of 60-65°C for 24 hours, separate the stalks and leaves, and add ingredients to the separated stalks of ginkgo leaves (see the recipe for the ingredients) One), the addition is 7.1kg; evenly spray the Chinese herbal medicine extract (the content of ginkgo leaf and white ginseng is 32%) that has been prepared in advance containing ginkgo biloba, white ginseng, astragalus, saffron, and apocynum, and wait for the leaf material to dry When the water content reaches 15-16%, balance for 12 hours and shred; then evenly add flavor and fragrance equivalent to 0.3kg of dry weight of leaves (see formula 2 for the flavoring formula), and dry twice to control the water content at 11.5 Between -13%, carry out silk storage balance for 24 hours; then roll the processed silk material, then carry out filter tip fitting, and finally carry out packagin...

Embodiment 2

[0021] Same as Example 1, the only difference is that the mixture of 90 kg of ginkgo leaves and 10 kg of honeysuckle is used as the rolled filling material, and the quality of the obtained product is close to that of Example 1.

Embodiment 3

[0023] Same as Example 1, the only difference is that the Chinese herbal medicine extract containing ginkgo biloba, white ginseng, astragalus, saffron, and apocynum is not added, and the product obtained has a strange taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com