Automatic regulation method for comprehensive combustion in circular fluidized bed boiler

A circulating fluidized bed and automatic adjustment technology, which is applied to fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problems of automatic adjustment that cannot be long-term, stable input, adjustment out of tolerance, etc., and achieve high inertia , Eliminate disturbances, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

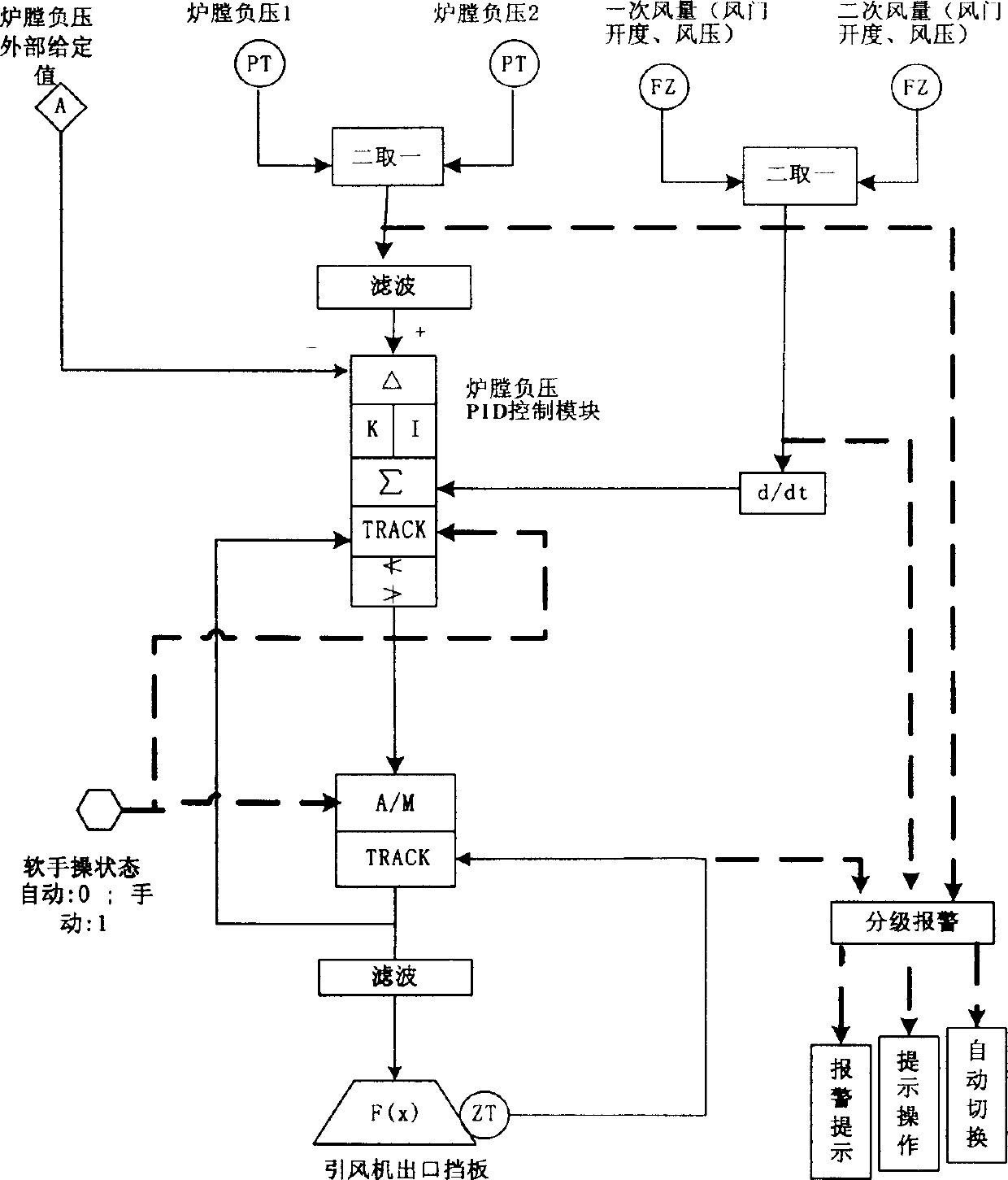

[0020] Referring to Fig. 1, in the step (1) of technical case:

[0021] The furnace negative pressure adjustment adopts the mode of single-loop adjustment, that is, the furnace negative pressure given value and the furnace negative pressure process measurement value enter the furnace negative pressure PID control module, and the PID control module outputs to the soft hand operator module, and the soft hand operator The module outputs to the external actuator - the outlet baffle of the induced draft fan or the frequency converter, and the air supply volume is used as feedforward;

[0022] The parameters of the furnace negative pressure PID control module are set as: proportional band P=120%~180%, integration time Ti=40~80s, output change rate=0.3%~1%; air supply volume feedforward is set as: Differential coefficient Kd2 = 1 ~ 2, differential time Td2 = 10 ~ 20s.

[0023] In the furnace negative pressure single-loop adjustment, when there are two actuators, a balance module of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com